ZMC GL80AF R134a Hermetic Compressor

ZMC GL80AF R134a Hermetic Compressor: Technical Profile, Applications and Professional Opinion

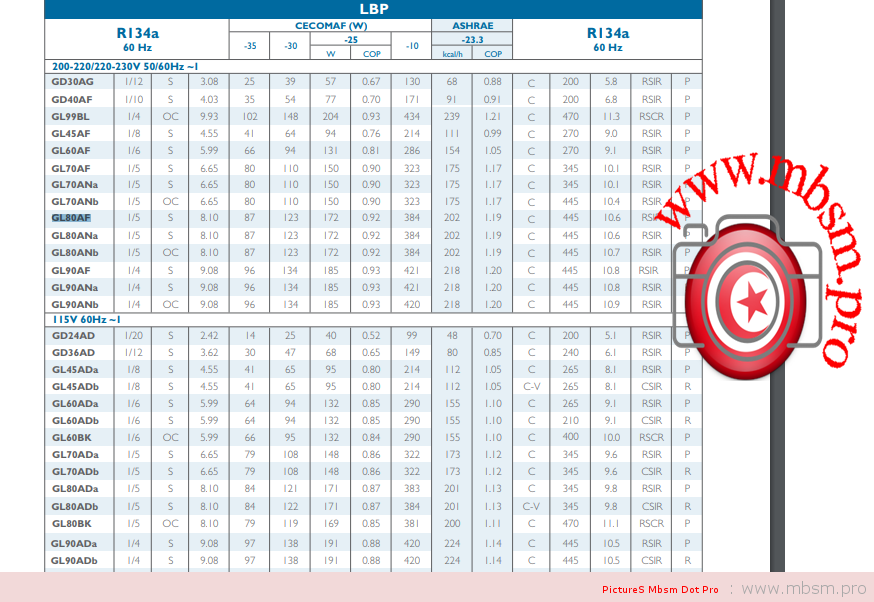

The image shows a ZMC GL80AF hermetic compressor designed for domestic refrigeration using refrigerant R134a, manufactured in Egypt and widely used as a 1/5 HP replacement in household refrigerators and coolers. This model belongs to the GL‑AF family of ZMC low‑back‑pressure compressors, optimized for energy‑efficient operation on 220–230 V, 50/60 Hz single‑phase supply in warm climates such as North Africa and the Middle East.

Main identification

The label in the photo clearly indicates the marking GL80AF, the brand ZMC / ZEM, the refrigerant R134a and the supply range 200–220 V / 220–230 V at 50/60 Hz, with manufacture noted as “Made in Egypt”. In ZMC’s catalog, GL‑series compressors in the 80 class are rated around 1/5 HP, with displacement close to 8 cm³ and low‑back‑pressure duty for freezer and refrigerator applications using capillary tubes.

Table – ZMC GL80AF key data (typical catalog values for GL80 R134a series)

Technical context and typical uses

Within ZMC’s R134a range, the GL80AF is positioned between smaller GD40/GL45 units and larger GL90 models, offering a balance between cooling capacity and electrical consumption for medium‑size domestic refrigerators and small commercial coolers. Installers commonly use it as a service replacement for 1/5 HP R134a compressors in brands such as Electrolux, Zanussi and regional OEM manufacturers, particularly where a robust compressor is needed for high‑ambient conditions up to 43 °C.

The GL80AF is designed for use with capillary expansion devices, mineral‑free ester oil compatible with R134a and standard household line voltages, making it straightforward to integrate into existing systems that originally used CFC‑12 or early R134a units of similar capacity. For correct operation, technicians must respect ZMC’s recommendations regarding oil type, charge amount, airflow around the compressor shell and proper matching between evaporator, condenser and capillary tube dimensions.

Installation, replacement and troubleshooting notes

When replacing a failed compressor with a GL80AF, professionals typically verify that the original unit had a similar displacement and LBP duty rating and then adapt mounting springs, suction and discharge connection diameters if needed. Attention to cleanliness of the refrigeration circuit—nitrogen purging during brazing, filter‑drier replacement and precise R134a charging—is essential to guarantee reliability and avoid lubricant breakdown or acid formation inside the hermetic shell.

Electrical checks before start‑up usually include measuring winding resistances, confirming the correct RSIR/RSCR starting components (start relay, overload protector and capacitor if required) and ensuring that the supply voltage at the compressor terminals stays within the 187–264 V working range specified for ZMC R134a models. Because GL80‑class compressors are optimized for low back‑pressure, using them outside their intended evaporating temperature range (for example in high‑back‑pressure air‑conditioning duty) can lead to overheating, high current draw and premature mechanical failure.

Reference images and documentation

Technicians and buyers seeking more visuals can consult ZMC’s official product pages and specialist refrigeration catalogs, which show close‑up images of GL‑series compressors, terminals and mounting hardware. In addition, Mbsmgroup maintains its own photographic documentation and comparison articles featuring the GL80AF in real workshop conditions, including the same type of label as seen in the attached image.

Several reliable PDF resources provide detailed performance data, cooling‑capacity curves and application limits for ZMC R134a compressors, including GL80‑family models. These catalogs list parameters such as displacement, current, COP, recommended capillary tube sizes and wiring diagrams, giving professionals the information they need to design or repair systems around the GL80AF platform.