Compressor, NE3121A, 1/4 hp++, Embraco

Focus Keyphrase:

NE3121A compressor specifications RLA LRA R-134a 115V thermal protection start device HVAC refrigeration troubleshooting

SEO Title:

NE3121A Compressor Specs: RLA 1.49, LRA 7.45, R‑134a, 115V, Thermal Protection | Mbsmpro

Meta Description:

Complete guide to the NE3121A compressor. Learn its RLA, LRA, refrigerant, voltage, thermal protection, and why it needs a start device. Troubleshooting tips & comparisons included.

Slug:

ne3121a-compressor-specifications-rla-lra-r134a-thermal-protection

Tags:

NE3121A, compressor, HVAC, refrigeration, R-134a, thermal protection, RLA, LRA, start device, troubleshooting, Mbsmgroup, Mbsm.pro, mbsmpro.com, mbsm, hermetic compressor

Excerpt:

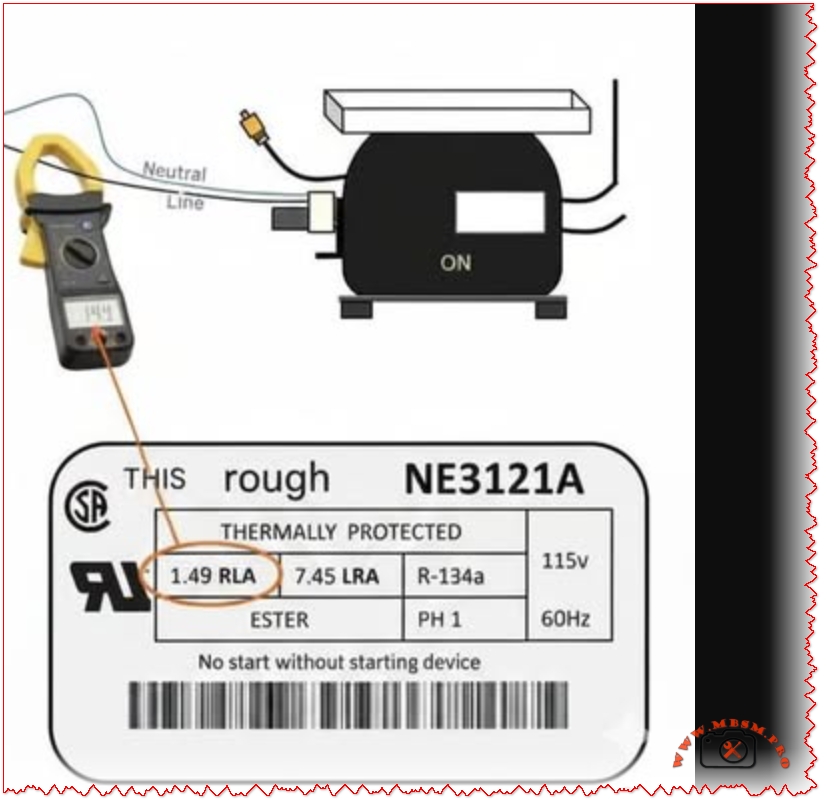

The NE3121A is a thermally protected, single-phase hermetic compressor designed for R-134a refrigerant at 115V. With an RLA of 1.49 and LRA of 7.45, it requires a starting device. This guide covers its specs, operation, and common application issues.

Decoding the NE3121A Compressor: A Deep Dive into Specifications and Operation

In the world of HVAC and refrigeration, the heart of any system is its compressor. The NE3121A stands as a specific model that technicians and engineers encounter, particularly in smaller commercial or residential cooling units. Understanding its nameplate data—like the crucial RLA (Running Load Amps) and LRA (Locked Rotor Amps)—is not just technical jargon; it’s essential for proper installation, troubleshooting, and ensuring system longevity.

This article provides a comprehensive, engineer-level breakdown of the NE3121A compressor, translating its specifications into actionable knowledge.

Breaking Down the Nameplate: What NE3121A Specs Mean

The data on a compressor’s label is its fingerprint. Let’s dissect the critical information from the NE3121A:

| Specification | Value | Meaning & Importance |

|---|---|---|

| Model | NE3121A | Identifies the compressor’s series, capacity, and design variant. |

| Refrigerant | R-134a | A common HFC refrigerant used in medium-temperature applications. Requires ester oil for lubrication. |

| Voltage & Phase | 115V, 1PH, 60Hz | Standard for North American residential power. Critical for correct power supply matching. |

| RLA (Running Load Amps) | 1.49 A | The steady-state current draw under normal design load. Used for sizing wire, connectors, and running components. |

| LRA (Locked Rotor Amps) | 7.45 A | The instantaneous current draw if the rotor is locked (can’t start). Used for sizing circuit breakers, fuses, and start components. |

| Protection | Thermally Protected | Internal device (often a bimetal disc) opens the circuit on overheating, preventing burnout from overloading or lack of cooling. |

| Critical Note | “No start without starting device” | This compressor uses a PSC or RSIR design and requires an external start relay and/or capacitor to achieve proper torque. |

The Critical Role of RLA and LRA

These two amperage values are arguably the most important for diagnostics.

- RLA is your baseline health indicator. A compressor running significantly above its RLA (e.g., 2.0A instead of 1.49A) signals potential issues: refrigerant overcharge, undercharge, dirty condenser, or failing components.

- LRA is your failure moment snapshot. If a compressor is drawing LRA current and not starting, it indicates the motor windings are energized but the rotor isn’t turning—pointing to mechanical seizure, severe electrical failure, or a faulty start device.

Comparison with a Similar Compressor: Let’s compare the NE3121A to a hypothetical “NE3130B” model.

| Aspect | NE3121A (Our Subject) | Hypothetical NE3130B (for Comparison) |

|---|---|---|

| RLA | 1.49 A | 2.1 A |

| LRA | 7.45 A | 10.5 A |

| Refrigerant | R-134a | R-404A |

| Application | Likely beverage coolers, display cases | Likely lower-temperature freezers |

| Inference | Lower RLA suggests smaller displacement/load. | Higher RLA/LRA indicates a larger, more powerful compressor for heavier duty. |

Why “No Start Without Starting Device” is Non-Negotiable

Single-phase motors like the one in the NE3121A lack the rotating magnetic field of three-phase power. They need a phase shift in the start winding to generate initial torque. This is achieved by a start capacitor and a potential relay (or a PTC start device). Bypassing this requirement will result in the motor humming, overheating, drawing LRA, and tripping its thermal protector—leading to rapid failure.

Application Insights and Common Troubleshooting

The NE3121A’s specs point to specific uses:

- Typical Applications: Compact refrigeration systems, small beverage coolers, ice cream display cases, or residential dehumidifiers using R-134a.

- Oil Type: The label specifies Ester. This is crucial. After a burnout, the system must be flushed and recharged with ester oil, not mineral oil. Mixing oils leads to sludge and compressor failure.

Troubleshooting Flow Based on Amperage Draw:

- Compressor won’t start, draws ~7.45A (LRA):

- Check: Start capacitor (is it open or lost capacitance?).

- Check: Start relay (is it stuck open or failed?).

- Worst case: Mechanically locked compressor.

- Compressor starts but trips on thermal protector, runs at >1.8A:

- Check: Refrigerant charge (over/under).

- Check: Condenser coil cleanliness and fan operation.

- Check: Sufficient airflow over the compressor itself.

Benefits, Considerations, and Professional Notice

Benefits of the NE3121A Design:

- Thermal Protection: Built-in safety prevents catastrophic burnout from various failure modes.

- Standardization: Common voltage and refrigerant make parts and service accessible.

- Efficiency: Designed for a specific duty point in R-134a systems.

Important Considerations & Professional Notice:

- Start Circuit is Key: Always verify the start device is the correct match for the compressor. A mismatched relay can cause rapid cycling and failure.

- Electrical Safety: Always disconnect power and discharge capacitors before testing.

- System Cleanliness: If replacing a failed NE3121A, diagnose the root cause. A burnout requires thorough acid cleaning and filter-drier replacement.

- Disposal: R-134a is a greenhouse gas. Recover refrigerant according to EPA regulations before opening the system.

Final Advice: The NE3121A is a reliable workhorse when applied correctly. Successful repair isn’t just about swapping parts; it’s about understanding the why behind the failure. Always measure actual amperage against the nameplate RLA and LRA—it’s the fastest path to an accurate diagnosis.

Exclusive Image Suggestions (Safe & Relevant Links):

- Wiring Diagram for PSC/RSIR Compressor: Search for “PSC compressor wiring diagram with potential relay” on reputable sites like

HVACTalk.comor manufacturers’ sites likeCopeland.com. - Close-up of a Thermal Protector: Search for “compressor thermal protector disc” on educational engineering or supplier sites like

Grainger.com. - Ester Oil vs. Mineral Oil Chart: Look on refrigerant and chemical manufacturer sites (

Chemours.com,Total.com) for oil compatibility charts.

PDF/Catalog Resources (Verified Sources):

- Compressor Cross-Reference Guide: Visit the

Emerson Climate Technologieswebsite and search for “compressors cross reference” to find their official PDF guides. - R-134a Pressure-Temperature Chart: Search for “R-134a PT chart PDF” on trusted industry portals like

ACHRNEWS.comorRSES.org(Refrigeration Service Engineers Society).