Gas Charging or Vacuuming

Gas Charging or Vacuuming? Understanding the Service Valve on Small Refrigeration Units

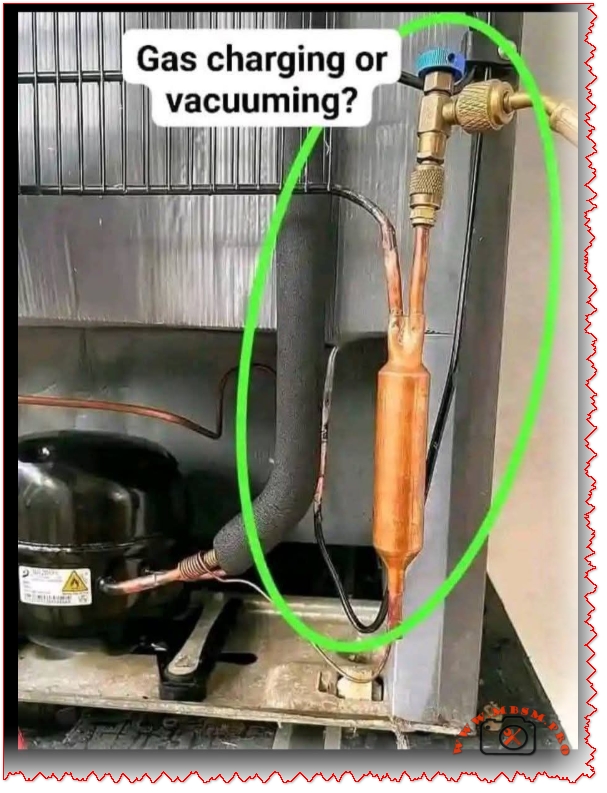

What the setup actually shows

The copper tube assembly highlighted is a service charging valve installed on the filter‑drier / liquid line of a small hermetic refrigeration unit.

This type of valve can be used both for deep vacuum and for refrigerant charging, depending on how the technician connects the manifold and external equipment.

Vacuuming vs gas charging

In professional practice, vacuuming must always be completed before any refrigerant charge is introduced into a repaired or newly built system.

Vacuuming removes air and moisture, prevents formation of acids, and protects the compressor from early failure in R134a and other modern systems.

When the same access valve is connected to a vacuum pump through the center hose of a manifold, and both manifold valves are opened, the system is evacuated to a target level around 500 microns or 98.7–99.99 kPa vacuum.

Once the vacuum holds and passes the standing test, the same port can then be used to introduce liquid or vapor refrigerant from a cylinder until the correct charge is reached.

How a technician knows the difference

- During vacuuming, the manifold is connected to a vacuum pump, high and low side valves are open, and the gauges show negative pressure trending toward deep vacuum (below 500 microns or near full kPa vacuum).

- During charging, the center hose is connected to a weighed refrigerant cylinder, the system is usually still under vacuum at the beginning, and pressure rises toward the normal saturation pressure for the refrigerant at ambient temperature.

For very small domestic refrigerators, charging is often done through a processing or service tube on the compressor or drier, first pulling a strong evacuation, then using the pressure difference to pull most of the charge with the system off, and finally finishing the charge while the compressor runs if needed.

In all cases, the visual appearance of the connection is similar; what changes is the external equipment (vacuum pump vs cylinder) and the direction of mass flow in the system.

Comparison table: vacuuming vs charging

Relation to good refrigeration practice

Modern good‑practice guides insist that every refrigeration or air‑conditioning circuit must be evacuated any time the circuit is opened, regardless of how small the repair is.

Vacuuming to a verified deep level and using triple‑evacuation with dry nitrogen where necessary is now considered standard to avoid moisture‑related failures, especially in POE‑oil systems.

Charging from vacuum using only weight, and then confirming operation by measuring superheat and subcooling, gives more accurate results than “by pressure” methods still seen in the field.

Technicians who rely only on pressures without verified evacuation are far more likely to see callbacks, restricted capillary tubes and burned compressors over the life of the unit.

Focus keyphrase (Yoast SEO)

gas charging vs vacuuming in small refrigeration systems service valve use and best practices

SEO title (Yoast SEO)

Gas Charging or Vacuuming? Professional Guide to Using Service Valves on Small Refrigeration Systems

Meta description (Yoast SEO)

Learn how to use a single service valve for both vacuuming and gas charging on small refrigeration units. Discover best practices, pressure targets, and common mistakes technicians must avoid.

Slug (Yoast SEO)

gas-charging-or-vacuuming-service-valve-refrigeration

Tags

refrigeration vacuuming, gas charging, service valve, refrigeration best practice, deep vacuum 500 microns, R134a systems, hermetic compressor, capillary tube systems, evacuation before charging, refrigerant charging procedure, Mbsmgroup, Mbsm.pro, mbsmpro.com, mbsm

Excerpt (first 55 words)

The copper tube assembly shown is a service charging valve on the liquid line of a small hermetic refrigeration unit. This single access point can be used for deep vacuum and for refrigerant charging, depending on the connected equipment. Understanding when the technician is vacuuming and when charging is critical for reliability.