NOCT-27545 & NRVT35-275 Tool Guide

Focus Keyphrase:

NOCT-27545 double-ended nut driver ratchet wrench folding tubing reamer bar-type flare tool HVAC refrigeration tool kit

SEO Title:

NOCT-27545 & NRVT35-275 Tool Guide: Ratchet Wrench, Flaring Tool, Tube Reamer Uses | Mbsmpro

Meta Description:

Professional review of the NOCT-27545 ratchet wrench & NRVT35-275 flaring tool kit. Learn how to use folding tubing reamers, bar-type flare tools, and hole sizing bars for HVAC work.

Slug:

noct-27545-nrvt35-275-hvac-tool-ratchet-flare-reamer-guide

Tags:

NOCT-27545, NRVT35-275, HVAC tools, refrigeration tools, ratchet wrench, flaring tool, tubing reamer, bar-type flare, tube cutter, hole sizing bar, Mbsmgroup, Mbsm.pro, mbsmpro.com, mbsm, technician tools

Excerpt:

The NOCT-27545 ratchet wrench and NRVT35-275 flaring tool represent specialized HVAC instrumentation. This guide explains their functions, from creating perfect 45° flares to reaming tubing and driving fasteners in tight spaces, ensuring leak-free, professional installations.

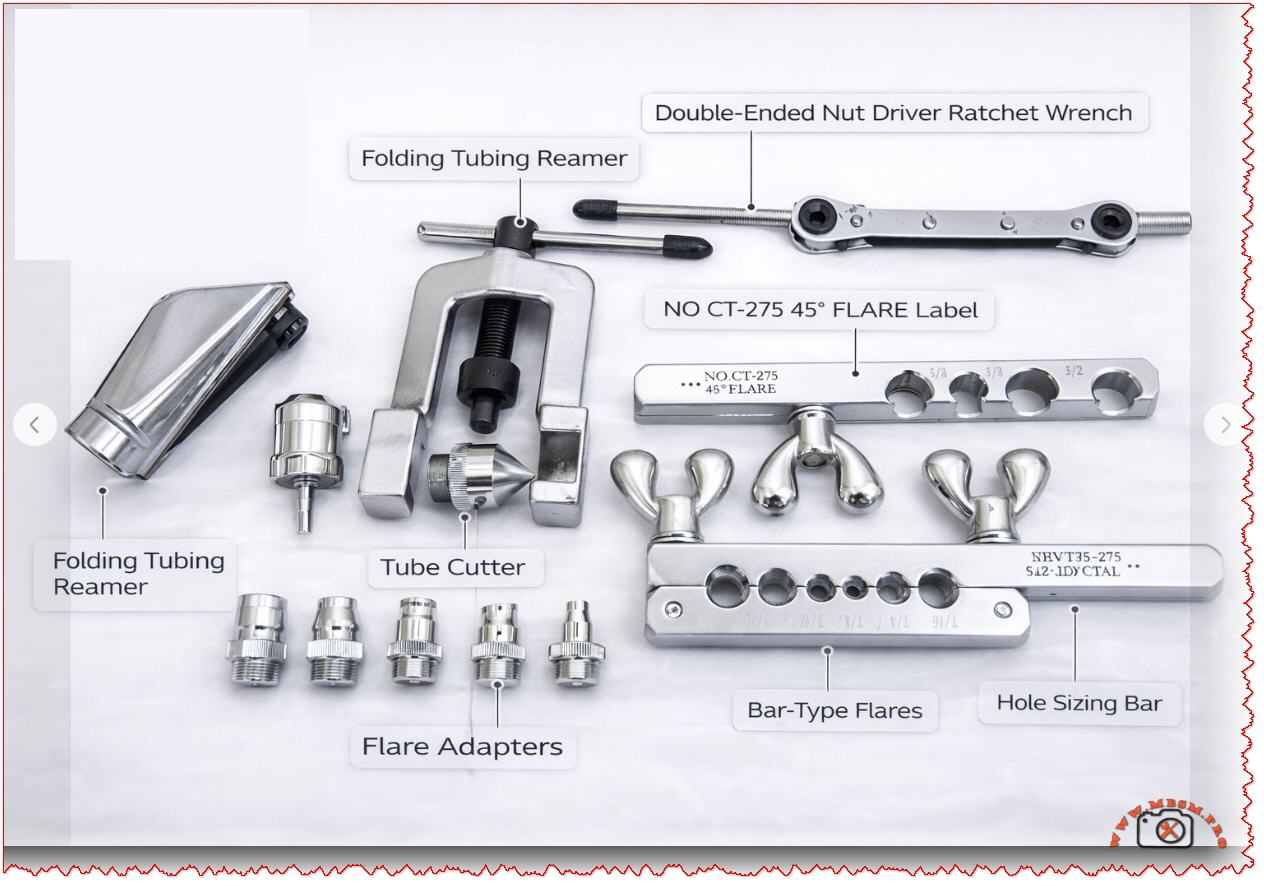

HVAC Tool Mastery: Decoding the NOCT-27545 Ratchet Wrench and NRVT35-275 Flaring Kit

Every seasoned HVAC and refrigeration technician knows that the difference between a leak-prone, amateur installation and a flawless, professional one often comes down to the specialized tools in their bag. While flashy power tools get attention, it’s the precision instruments—like those in a comprehensive flaring and driving kit—that ensure longevity and reliability. Today, we’re breaking down a set of tools centered around two key items: the NOCT-27545 double-ended nut driver ratchet wrench and the NRVT35-275 bar-type flaring tool kit.

These aren’t generic hardware store finds; they’re purpose-built for the specific, demanding tasks of refrigeration and gas line work.

Core Tool Analysis: Function and Specification Breakdown

Let’s dissect the primary tools indicated, translating model numbers into practical understanding.

1. The NOCT-27545: The Double-Ended Ratchet Wrench

This tool solves a common field problem: accessing fasteners in confined spaces behind linesets or inside tight equipment compartments.

| Feature | Specification / Benefit |

|---|---|

| Design | Double-ended, reversible ratchet mechanism. |

| Drive Sizes | Typically features two most-used sizes (e.g., 1/4″ and 5/16″ hex). |

| Primary Use | Installing service valves, panel screws, solenoid valves, and other fittings where a full swing of a standard driver is impossible. |

| Advantage over Standard Driver | The ratcheting action allows you to tighten or loosen nuts without removing the tool, saving immense time and frustration in tight quarters. |

Comparison to Standard Tools:

A standard nut driver requires ~30 degrees of clearance for repositioning. In a tight spot, you might get one partial turn before having to remove and reposition it. The NOCT-27545 ratchet allows for full, continuous torque application with as little as a 5-degree swing, making it indispensable for condenser or evaporator service.

2. The NRVT35-275: Bar-Type Flaring Tool Kit

This is the heart of leak-free connection work for soft copper tubing (Type L, ACR). The “45” in related labels signifies the 45-degree flare standard for SAE/JIC fittings, ubiquitous in HVACR.

| Component (from image) | Critical Function |

|---|---|

| Bar-Type Flaring Tool (Main Body) | Holds the tubing secure in precise, sized holes for a consistent flare. Superior to cheaper clamp-style tools for repeatability. |

| Flare Adapters (45° Cone) | The forming tool that is pressed/driven into the clamped tube end to create the actual 45-degree flare shape. |

| Hole Sizing Bar | A reference tool with graduated holes to quickly verify the outer diameter of tubing, ensuring you use the correct clamp hole. |

| Folding Tubing Reamer | Used after cutting tubing with a tube cutter to remove the internal burr. This is non-negotiable. A left-in burr creates turbulence, restricts flow, and can trap debris. |

The Critical Path to a Perfect Flare: A Step-by-Step Process

Using these tools correctly is a systematic process. Here’s how they work together:

- Cut: Use a sharp tube cutter (like the S42-LDYCTAL implied) for a square, clean cut. Never use a hacksaw for this step.

- Ream: Immediately deploy the folding tubing reamer. Insert it into the tube end and rotate to cleanly remove the internal burr. Deburr the outside edge lightly.

- Size: Double-check your tube’s OD using the hole sizing bar. Match it exactly to the corresponding hole on the flaring bar.

- Clamp: Insert the tube into the correct hole on the bar-type flaring tool, leaving the appropriate amount of tube protruding (typically the height of the flare nut).

- Flare: Apply a drop of refrigerant oil to the flare adapter’s 45-degree cone. Screw the adapter into the bar and drive it down smoothly until it forms a complete flare. Do not over-tighten.

- Inspect: A perfect flare will be concentric, smooth, and have a uniform matte finish. No cracks, wrinkles, or tool marks should be present.

Benefits, Professional Advice, and Common Pitfalls

Benefits of Using This Specialized Kit:

- Leak Prevention: A properly made flare is the first and most critical line of defense against refrigerant leaks.

- Efficiency: The ratchet wrench and integrated tools speed up installation and service work dramatically.

- Professional Results: Consistency is key. These tools provide repeatable, manufacturer-spec results every time.

Professional Notice & Critical Warnings:

- Material Matters: These tools are designed for soft copper tubing. Do not attempt to flare hard-drawn copper or other metals without specific, rated tools.

- The Reamer is Not Optional: Skipping the reaming step is the #1 cause of contamination-related failures and flow restriction. The small burr can break off and travel into a metering device.

- Flare Inspection: Always inspect the flare visually and with a gauge if possible before assembly. A flawed flare must be cut off and re-done.

- Torque Specs: When connecting the flare nut, use a torque wrench according to the fitting manufacturer’s specifications. Over-tightening can shear the flare, and under-tightening will guarantee a leak.

Value Comparison to Universal Kits:

While all-in-one “HVAC tool kits” are available, they often compromise on the quality of these critical forming tools. A dedicated, professional-grade bar-type flaring kit (like the NRVT series) and a precision ratchet driver (like the NOCT) will outperform universal kits in durability, result quality, and ease of use on the job daily. Investing in these separates often costs less in the long run than replacing a failed multi-tool.

Final Recommendation: For any technician serious about refrigeration or fuel gas line work, a high-quality bar flaring tool and a reliable double-ended ratchet are not just purchases; they are foundational investments in your craft and reputation. Master these tools, and you eliminate one of the most common failure points in any system you install.

Exclusive Image Suggestions (Safe & Relevant Links):

- Sequence of a Perfect Flare: Search for “step by step bar flaring tool process” on professional tool manufacturer sites like

RIDGID.com,ImperialTools.com, orYellowJacket.com. - Internal Burr Diagram: Look for “tube cutting internal burr diagram” on educational engineering or HVAC training sites like

ESCO InstituteorHVAC School. - Flare Inspection Gauge: Search for “SAE 45-degree flare inspection gauge” on supplier sites like

Johnstone SupplyorUnited Refrigeration.

PDF/Catalog Resources (Verified Sources):

- RIDGID Flaring Tool Manual: Visit the

RIDGID Toolswebsite and search for “Flaring Tool Instruction Sheet” for official, detailed usage and safety PDFs. - ESCO Institute Refrigeration Piping Handbook: Search for “ESCO refrigerant piping practices PDF” for comprehensive guides on tubing preparation, which heavily features flaring and reaming procedures.

- SAE J514 Hydraulic Flare Fitting Standards: For the truly technical, searching “SAE J514 standard” will lead to the definitive specification documents for 45-degree flare fittings.