Start Run Capacitor Failure, Causes

Mbsmpro.com, HVAC, CBB65 SH, 50 µF, 450 VAC, Capacitor Explosion, Start Run Capacitor Failure, Causes, Diagnosis, Protection, Air Conditioner

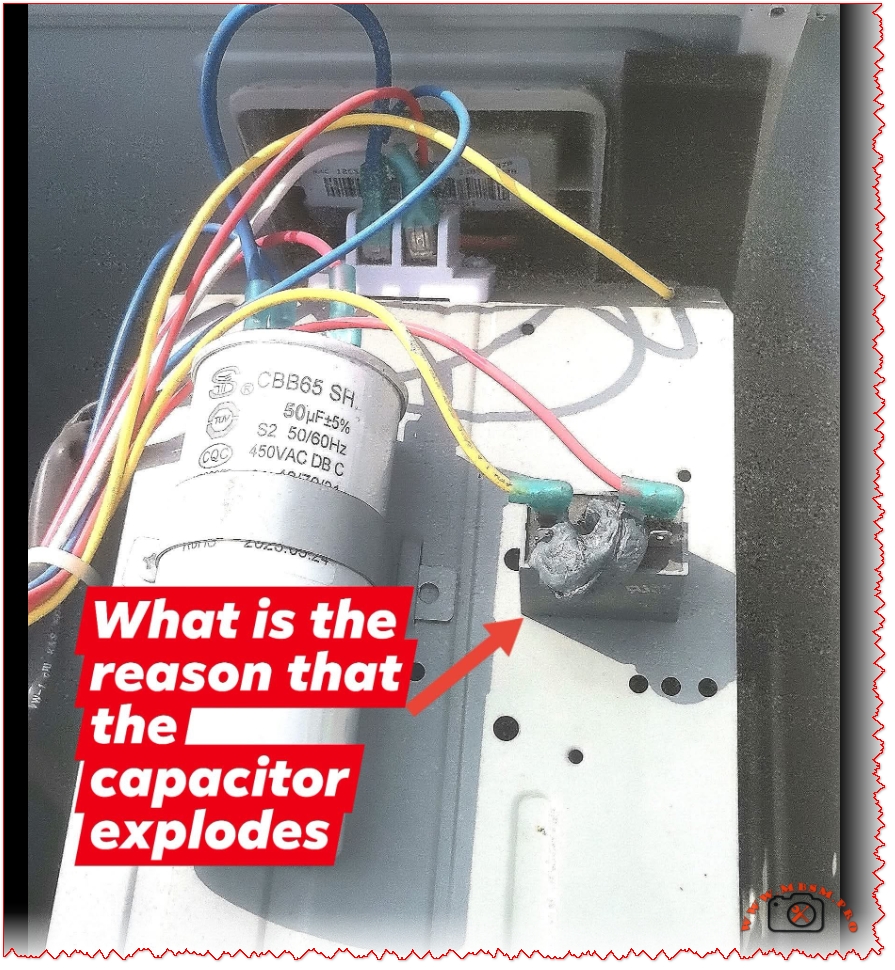

Why HVAC capacitors explode

An AC motor run capacitor such as the CBB65 SH usually explodes when it is forced to work beyond its electrical or thermal limits, or when the start‑assist components fail and leave it in the circuit too long. This overstress breaks down the internal dielectric, creates gas and pressure, and finally ruptures the metal can or plastic top.

Main electrical causes

- Overvoltage on the supply line: When the real working voltage is higher than the 450 VAC rating, the electric field in the capacitor becomes too strong, puncturing the dielectric and causing an internal short that can end in a violent burst. Power surges, lightning and unstable grids are typical sources of this problem in residential and light commercial HVAC systems.

- Start capacitor or potential relay failure: In systems that use a start‑assist (start capacitor + potential relay or PTC thermistor), a failed relay can keep the start capacitor in series with the run capacitor and motor for too long, overheating the assembly until the weakest capacitor explodes.

- Short circuits and wiring errors: Miswiring between C, FAN and HERM terminals, damaged insulation or loose terminals increase current and can create localized heating and arcing at the capacitor lugs, which accelerates internal failure.

Thermal and environmental stress

- Overheating from high ambient temperature: Capacitors mounted near hot compressor shells or in outdoor units exposed to direct sun often run above their design temperature, which speeds dielectric aging and raises internal pressure.

- Continuous heavy load and long duty cycles: When the compressor or fan runs for long periods because of undersized equipment, dirty condensers or refrigerant leaks, the capacitor carries high ripple current and runs hot, again pushing it toward bulging and rupture.

- Poor ventilation inside the control box: A small metal enclosure with no airflow traps heat around the capacitor, especially when several components (contactors, relays, resistors) are mounted close together.

Aging, quality and mechanical factors

- Aging of the CBB65 capacitor: Over years of service the polypropylene film and internal connections lose strength; bulging, leaking oil or swelling are classic warning signs just before failure.

- Low‑quality components: Cheap capacitors with thin film, poor impregnation and weak safety vents fail much earlier than branded models, and they are more likely to burst instead of opening safely.

- Vibration and mechanical damage: If the capacitor is not firmly fixed or is mounted close to vibrating copper tubes, repeated shock can crack the internal connections or case, leading to moisture ingress and eventual explosion.

Effects on the HVAC system

A blown capacitor is not just a bad part; it affects the entire air‑conditioning circuit.

- The compressor may hum but not start, draw locked‑rotor current and overheat its windings, risking a burnt motor.

- The outdoor fan can stop or run slowly, which increases head pressure and temperature and may trip thermal protection or high‑pressure switches.

- Repeated capacitor explosions without proper diagnosis usually indicate deeper issues, such as incorrect voltage, wrong µF size, or a defective start‑assist device.

Comparison: HVAC capacitor failure vs. other AC failures

| Failure type | Main symptom | Root cause | Risk level for compressor |

|---|---|---|---|

| Run/start capacitor explosion | Loud pop, oil leak, swollen can, motor will not start or runs weak | Overvoltage, overheating, start‑relay fault, poor quality capacitor | Very high: repeated locked‑rotor starts overheat windings |

| Fan motor failure without capacitor damage | Fan not turning, capacitor tests normal | Worn bearings, open winding | Medium: high head pressure but no electrical blast |

| Contactor welding closed | Unit runs non‑stop even with thermostat off | Overcurrent, contact wear | High: continuous running overheats compressor and capacitor |

| Refrigerant leak | Long run time, poor cooling, but capacitor may still test good | Mechanical leak in circuit | Indirect: long run time can overheat and age capacitor faster |

How to prevent capacitor explosions

- Match voltage and capacitance correctly: Always use replacement capacitors with at least the same voltage rating (for example 450 VAC) and the specified capacitance in µF; undersized or underrated parts are much more likely to fail.

- Control supply quality: Installing surge protection, checking for correct line voltage and ensuring solid grounding reduces overvoltage events that can puncture the dielectric.

- Replace start‑assist components together: When a start capacitor fails or explodes, replace the potential relay or PTC as well to avoid repeating the fault due to a device that keeps the capacitor in series too long.

- Improve cooling and layout: Keep the capacitor away from hot compressor surfaces, add ventilation openings in the control box and avoid tight bundles of heat‑producing parts around it.

- Adopt preventive maintenance: Periodic inspection for swelling, leaks, rusted terminals or discoloration allows technicians to change the capacitor early and avoid a violent rupture.

Key values and comparison table

The CBB65 SH capacitor in many residential units is typically a motor run type used for compressor or fan motors. The table compares this typical 50 µF model with other common HVAC capacitors.

| Parameter | CBB65 SH run capacitor | Typical start capacitor | Small fan run capacitor |

|---|---|---|---|

| Capacitance | 50 µF ±5% (example value) | 135–324 µF (wide range) | 3–10 µF |

| Voltage rating | 450 VAC | 250–330 VAC | 370–450 VAC |

| Duty | Continuous (motor running) | Short‑time start only | Continuous |

| Construction | Metallized polypropylene, oil‑filled or dry | Electrolytic, non‑polarized | Metallized polypropylene |

| Typical failure mode | Swelling, leaking, occasional explosion under severe stress | Violent rupture if left in circuit too long | Value drift, open circuit |

Yoast SEO elements for this article

Focus keyphrase (≤191 characters)

Exploding HVAC capacitor, CBB65 SH 50 µF 450 VAC, causes of capacitor explosion, overvoltage, overheating, start relay failure, air conditioner run and start capacitor protection

SEO title

Why the HVAC Capacitor Explodes: CBB65 SH 50 µF 450 VAC Failure Causes and Protection – Mbsmpro.com

Meta description

Learn why the CBB65 SH 50 µF 450 VAC capacitor in air conditioners explodes, from overvoltage and overheating to start‑relay faults, plus practical tests and protection tips for safer HVAC systems.

Slug

hvac-capacitor-explodes-cbb65-sh-50uf-450vac-causes-protection

Tags

Mbsmgroup, Mbsm.pro, mbsmpro.com, mbsm, HVAC capacitor, CBB65 SH, capacitor explosion, air conditioner repair, start capacitor failure, run capacitor failure, overvoltage protection, compressor not starting, AC maintenance

Excerpt (first 55 words)

An AC motor run capacitor such as the CBB65 SH usually explodes when it is forced to work beyond its electrical or thermal limits, or when the start‑assist components fail and leave it in the circuit too long. This overstress breaks down the dielectric, creates internal gas and pressure, and finally ruptures the can.