Types of Electrical Wires and Their Uses

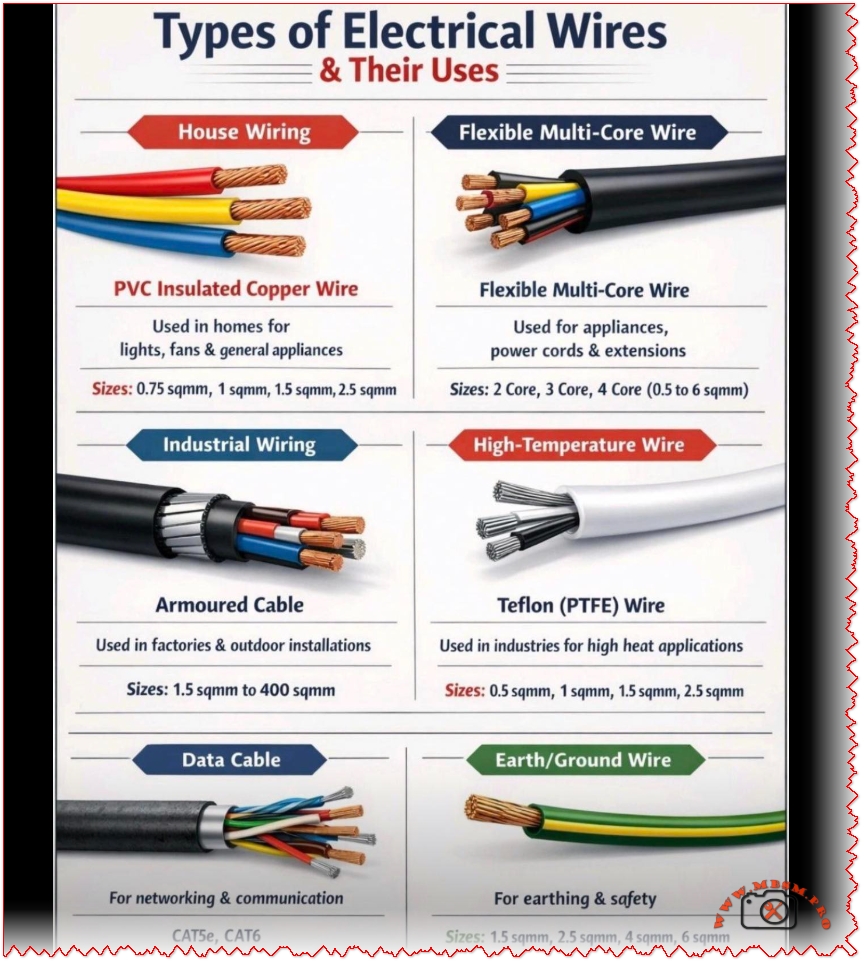

Types of Electrical Wires and Their Uses: A Practical Guide for Home, Industry, and Data Systems

Overview of Electrical Wire Categories

Modern installations use several wire families, each optimized for voltage level, environment, flexibility, and temperature range.

Choosing the right type reduces losses, prevents overheating, and keeps residential, industrial, and communication systems compliant with safety standards.

House Wiring – PVC Insulated Copper Wire

PVC‑insulated copper conductors are the standard choice for lights, sockets, and small appliances in homes and small commercial premises.

Typical solid or stranded sizes for internal circuits range from 0.75 sqmm to 2.5 sqmm, covering lighting points, general outlets, and low‑power equipment.

Typical house wiring sizes and uses

PVC provides good dielectric strength up to 300/500 V or 450/750 V while remaining economical and easy to strip during installation.

However, its temperature limit (generally around 70–90 °C depending on design) means it is not suited to very high‑temperature locations such as inside ovens or near heating elements.

Flexible Multi‑Core Wire for Appliances and Extensions

Flexible multi‑core cables bundle two to four insulated copper cores in one sheath for appliance cords, power strips, and temporary extensions.

These cables are usually rated for 0.5 to 6 sqmm per core and prioritized where repeated bending, coiling, and movement occur, such as with portable tools or vacuum cleaners.

Multi‑core vs single‑core in low‑voltage use

Because the sheath keeps all cores aligned, flexible multi‑core designs reduce installation time on appliances while improving strain relief and user comfort.

Industrial Wiring – Armoured Power Cable

Armoured cables combine copper or aluminum conductors, XLPE or PVC insulation, bedding, steel wire or tape armour, and an outer sheath for mechanical protection.

They are specified for factories, outdoor runs, underground feeders, and locations where impact, rodent damage, or accidental digging could occur, with cross‑sections that can exceed 400 sqmm for high loads.

Armoured cable compared with standard house wiring

The armour does not carry current but ensures continuity of service by preventing conductor damage in harsh environments.

Correct earthing of the metallic armour is essential so that fault currents clear protective devices quickly and safely.

High‑Temperature Wire – Teflon (PTFE) and Alternatives

PTFE (Teflon)‑insulated wire is engineered for high‑temperature and chemically aggressive environments in industrial ovens, furnaces, and aerospace harnesses.

PTFE cables typically operate from about −196 °C up to 260 °C continuously, with short‑term excursions even higher, far beyond the service range of PVC or standard rubber insulation.

Temperature capability comparison

PTFE is almost insoluble in common organic solvents and shows excellent resistance to oils and corrosive chemicals, making it suitable for refineries, chemical plants, and process sensors.

Because the material and processing are more complex, Teflon high‑temperature wire typically costs significantly more than PVC or silicone alternatives and is reserved for critical circuits.

Data Cable – Networking and Communication

Data cables such as Cat5e and Cat6 use twisted pairs of conductors with precise impedance and insulation to carry Ethernet and other digital signals.

They are specified not just by conductor size but also by bandwidth (MHz), maximum data rate, and installation category (horizontal cabling, patch cords, or outdoor shielded runs).

Data cable categories (simplified)

Unlike power cables, data cables are optimized for low noise, controlled crosstalk, and signal integrity; improper bending radius or untwisting can severely reduce performance.

They should be routed away from heavy power lines, contactors, or variable‑speed drives to minimize electromagnetic interference.

Earth / Ground Wire and Safety Role

Green‑yellow earth conductors provide a low‑impedance path that trips protective devices when a fault current flows to exposed metal parts.

In many installations earth conductors share the same copper material and similar cross‑section as the phase conductor, but color coding and connection rules are strictly defined by national standards.

Using a dedicated earth wire instead of relying on metallic conduits or water pipes improves fault‑clearing times and lowers touch voltage during insulation failures.

Regular continuity and loop‑impedance testing confirm that protective measures remain effective over the life of the installation.

Focus keyphrase for Yoast SEO

Focus keyphrase:

types of electrical wires and their uses for house wiring, flexible multi‑core cables, industrial armoured cables, high‑temperature PTFE wire, data cables, and earth grounding

SEO title for Yoast SEO

SEO title:

Types of Electrical Wires and Their Uses – House PVC, Flexible Multi‑Core, Armoured, PTFE High‑Temperature, Data and Earth Cables | Mbsm.pro

Meta description for Yoast SEO

Meta description:

Discover the main types of electrical wires and cables, from PVC house wiring and flexible multi‑core cords to industrial armoured, PTFE high‑temperature, data and earth conductors, with clear tables and comparisons for safer, smarter installations.

Slug for Yoast SEO

Slug:

types-electrical-wires-uses-house-industrial-data

Suggested tags

Tags:

types of electrical wires, electrical cable types, PVC house wiring, flexible multi core cable, armoured power cable, PTFE high temperature wire, data network cable, grounding wire, electrical safety, wiring guide, Mbsmgroup, Mbsm.pro, mbsmpro.com, mbsm

Excerpt (first 55 words)

Modern installations use several wire families, each optimized for voltage level, environment, flexibility, and temperature range. Choosing the right type reduces losses, prevents overheating, and keeps residential, industrial, and communication systems compliant with safety standards. PVC house wiring, flexible multi‑core cables, armoured feeders, PTFE high‑temperature conductors, and data or earth wires all play specific roles.