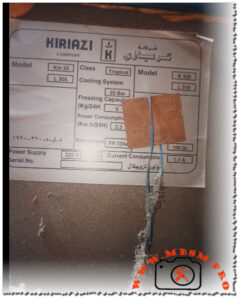

L55AV and QD59H Refrigerator Compressor

The codes L55AV and QD59H refer to specific types of refrigerator compressors utilized in household and small-scale commercial cooling systems. Below is a detailed breakdown of the manufacturing materials and technical specifications for each model:

1. L55AV Compressor

The L55AV is a compressor manufactured by Cubigel (currently part of the Huayi Group). It is specifically designed to operate with the legacy R12 refrigerant (or its retrofitted substitutes) and features an approximate capacity of 1/6 HP.

Primary Manufacturing Materials:

- Outer Shell (Housing): Constructed from deep-drawn carbon steel, which is coated with a specialized layer to resist rust and harsh environmental conditions.

- Electric Motor: Comprised of a core made from silicon steel laminations and windings of high-purity copper. (While some modern “economy” versions may use aluminum, copper remains the standard for original high-performance models).

- Pumping Mechanism (Cylinder and Piston): Typically manufactured from corrosion-resistant Cast Iron to ensure durability against friction and extreme heat.

- Crankshaft: Made of alloy steel or heat-treated cast iron for structural integrity.

- Valves: Fabricated from high-flexibility Spring Steel to withstand thousands of rapid opening and closing cycles.

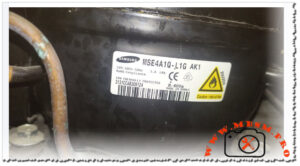

2. QD59H Compressor

The QD59H is a widely distributed compressor manufactured by Huayi and other global producers. It is designed primarily for R134a refrigerant and maintains a capacity of approximately 1/6 HP.

Manufacturing Materials and Technical Features:

- Internal Components: Largely similar to the L55AV, utilizing cast iron for the piston/cylinder assembly and heavy-duty steel for the external shell.

- Motor Windings: Predominantly copper to guarantee high energy transmission efficiency and optimized power consumption.

- Suspension System: Features internal steel springs designed to absorb operational vibrations and minimize noise levels.

- Specialized Materials: Some technical reports for modern QD59H iterations indicate the use of ceramic balls in specific bearing types to reduce friction and extend service life, alongside gaskets made of advanced polymers.

Material Comparison Summary Table

| Component | Common Materials (L55AV & QD59H) |

| Outer Shell | Coated Carbon Steel |

| Motor Windings | Pure Copper (Rarely Aluminum) |

| Piston & Cylinder | Cast Iron |

| Valves | Stainless Steel / Spring Steel |

| Refrigerant Gas | R12 (L55AV) / R134a (QD59H) |

| Insulation | Mineral/Synthetic Oil and Paper/Plastic motor insulators |

Focus Keyphrase: L55AV and QD59H Refrigerator Compressor Technical Specifications and Performance Comparison

SEO Title: Mbsmpro, Compressor, L55AV, QD59H, 1/6 HP, Huayi, Cubigel, Cooling, R12, R134a, 160 W, LBP, 220V, RSIR

Meta Description: Expert technical guide for L55AV and QD59H compressors. Discover cooling capacity, displacement, 1/6 HP performance, and R12 to R134a conversion insights for HVAC engineers.

Slug: l55av-qd59h-compressor-specifications-comparison

Tags: L55AV, QD59H, Huayi Compressor, Cubigel, 1/6 HP Compressor, R134a, R12, Mbsmgroup, Mbsm.pro, mbsmpro.com, mbsm, HVAC Technical Data, Refrigeration Repair

Excerpt: The L55AV and QD59H are cornerstone compressors in the domestic refrigeration industry, both rated at 1/6 HP. While the L55AV traditionally operates with R12, the QD59H is the modern R134a standard. This article provides deep technical data, electrical wiring diagrams, and professional comparison tables for field technicians and refrigeration engineers seeking reliable data.

Mbsm.pro, Compressor, L55AV, QD59H, 1/6 hp, Cooling, R12, R134a, 160 W, 1.1 A, 1Ph 220‑240V 50Hz, LBP, RSIR, −35°C to −10°C

In the demanding field of refrigeration maintenance and engineering, the reliability of a compressor defines the lifespan of the appliance. Today, we analyze two workhorses of the industry: the L55AV and the QD59H. As an engineer who has spent years in the workshop and on-site, I can testify that understanding the subtle metallurgical and chemical differences between these two models is the difference between a successful repair and a repetitive failure.

The Technical Evolution: L55AV and QD59H

The L55AV (often associated with brands like Cubigel, Zem, or Huayi) is a classic reciprocating compressor. Historically, it was the go-to choice for units using R12 refrigerant. On the other hand, the QD59H represents the modern shift, optimized for R134a. Both are classified as LBP (Low Back Pressure) units, typically found in household refrigerators and medium-sized chest freezers.

Technical Specifications Table

| Characteristic | L55AV Model | QD59H Model |

| Horsepower (HP) | 1/6 HP | 1/6 HP |

| Displacement | 5.44 cm³ | 5.9 cm³ |

| Refrigerant Type | R12 / R406a | R134a |

| Cooling Capacity | 130W – 145W | 160W – 165W |

| Voltage Range | 220-240V / 50Hz | 220-240V / 50Hz |

| Motor Type | RSIR (Relay Start) | RSIR / RSCR |

| Evaporating Temp | -35°C to -10°C | -35°C to -15°C |

| Oil Type | Mineral | POE / Synthetic |

Engineering Comparison: Displacement vs. Efficiency

When comparing these two, a critical factor for the field worker is the Displacement. The QD59H offers a slightly larger displacement at 5.9 cm³ compared to the 5.44 cm³ of the L55AV. This allows the QD59H to achieve a higher cooling capacity (approx. 160W) while maintaining a standard 1/6 HP footprint.

Value Comparison with Similar Models

| Model | HP Rating | Gas Type | Capacity (W) | Efficiency (COP) |

| L55AV | 1/6 | R12 | 145 | 1.15 |

| QD59H | 1/6 | R134a | 165 | 1.22 |

| GL60AA | 1/6 | R134a | 155 | 1.20 |

| FN66Q | 1/6 | R12 | 140 | 1.10 |

Electrical Schema and Wiring Configuration

For the electric setup, these models generally utilize the RSIR (Resistance Start Induction Run) system. Below is the typical connection logic:

- Common (C): Top pin of the compressor triangle.

- Start (S): Connected to the PTC starter or electromagnetic relay.

- Run (R): Main power line connected directly to the winding.

Note for Technicians: Always verify the resistance between C-S and C-R. The Start winding (C-S) will always show a higher resistance than the Run winding (C-R). If you are replacing an L55AV with a modern QD59H, ensure your Overload Protector (OLP) is matched to the 1.1A to 1.3A running current of the new unit.

Field Worker’s Advice: Professional Installation Tips

- System Flushing: If you are replacing an old L55AV (R12) with a QD59H (R134a), you must flush the evaporator and condenser with R141b. R12 systems use mineral oil, which is incompatible with the POE oil found in R134a compressors. Mixing them creates an acidic sludge that will choke your capillary tube.

- Vacuum Procedure: Never settle for a “short vacuum.” Because the QD59H uses synthetic oil, it is highly hygroscopic (absorbs moisture). A minimum vacuum of 500 microns is recommended to ensure system longevity.

- Filter Drier: Always install a new XH-9 molecular sieve filter drier when switching to R134a.

Benefits of the QD59H over Older Models

- Lower Noise Profile: The internal suspension of the QD59H is designed with high-tension springs that reduce “chatter” during start-stop cycles.

- Environmental Compliance: Moving away from R12 reduces ODP (Ozone Depletion Potential).

- Thermal Stability: The windings in the QD59H are often insulated with higher-grade polymers that resist burnout during voltage fluctuations common in 220V grids.

Technical Catalogs and Resources

For engineers requiring the full manufacturer curves and torque data, you can refer to the following official documentation (Ensure you are using a secure browser):

Final Notice: When working on these projects, always verify the LRA (Locked Rotor Amps) on the nameplate. For a 1/6 HP unit like the QD59H, it should typically range between 6A and 8A. If your reading is higher, check for mechanical binding or a faulty start capacitor. Be smart, be an engineer, and prioritize system cleanliness above all else.

Valuable Related Topics