MADEL KCA‑SUB zoning control module: wiring, functions and professional applications

MADEL KCA‑SUB zoning control module: wiring, functions and professional applications

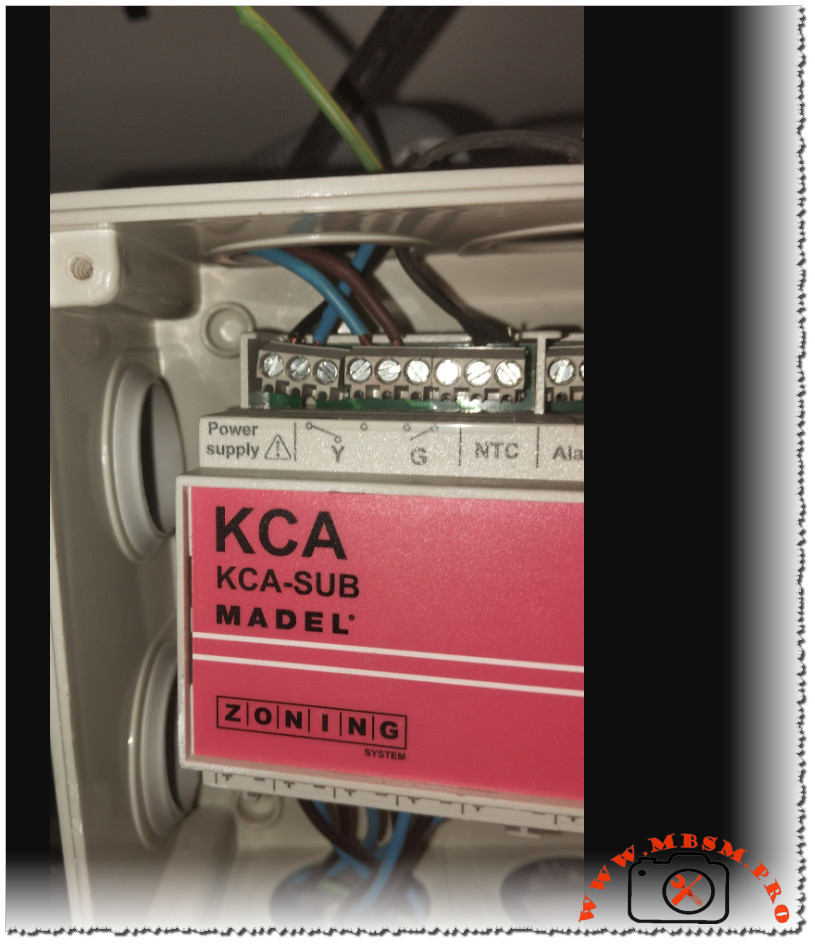

The MADEL KCA‑SUB is an electronic zoning controller designed to manage up to six independent air‑conditioning zones from a single ducted unit, improving comfort and energy efficiency in residential and light‑commercial projects. The photo shows the KCA‑SUB board installed in a junction box, with power, relay outputs and sensor terminals clearly labeled for field technicians.

Overview of the KCA‑SUB zoning system

The KCA‑SUB is part of MADEL’s Zoning System range, which uses motorized dampers and digital thermostats to regulate airflow to each room or zone. Each thermostat communicates with the control board via an RS485 bus, allowing centralized management of temperature and operation modes.

In “sub‑zone” configuration, the KCA‑SUB works on one to six branches of an existing ducted installation without modifying the logic of the main air‑conditioning unit. This makes it suitable for retrofits where only specific rooms need individualized temperature control.

Terminals and wiring shown in the image

On the upper edge of the module, the first block of terminals is reserved for the 230 V power supply and for control relays marked Y and G. According to the installer manual, Y and G are dry contacts intended to interface with the indoor unit’s cooling/heating and fan or start/stop inputs, following the wiring diagram provided by MADEL.

Next to the relay contacts, the board includes an NTC input for the return‑air sensor (typically a 10 kΩ thermistor) and an Alarm output that operates as a normally open potential‑free contact. In case of system fault, this alarm contact closes and can be connected to a BMS, a visual indicator or a safety circuit that shuts down the air‑handling unit.

Zoning channels and communication bus

The controller offers outputs for up to six motorized zone dampers, usually wired with red (positive) and black (negative) conductors for each actuator. The manual specifies a typical cable section between 0.75 and 1.0 mm² and recommends connecting any “master” zone to output 1 to ensure proper reference for system logic.

For communication, the KCA‑SUB uses an AB bus where terminal A is commonly wired in white and terminal B in blue, as also visible in many field installations. This two‑wire RS485 line links the control panel with all digital thermostats and must be daisy‑chained with correct polarity to guarantee stable communication.

Configuration and commissioning

Commissioning begins by supplying 230 VAC to the Power supply terminals and selecting the required number of zones with the rotary selector on the circuit board. Once the number of zones is set, technicians program each digital thermostat with its unique identification address and zone number using the SET‑UP menu described in the manual.

The controller can operate in classic “zoning” mode or in “sub‑zone” mode, where the KCA‑SUB manages only part of the installation while the original thermostat or controller keeps global authority over the unit. Seasonal change‑over between cooling and heating is typically commanded from the master thermostat, which sends the corresponding signal to the control board.

Operating indications and maintenance

Status LEDs on the front edge of the KCA‑SUB provide quick diagnostics for each zone and for the unit relays. In MADEL’s convention, a green LED indicates an open zone, a red LED indicates a closed zone, and illuminated Y or G LEDs mean that the respective relay is activated.

In case of malfunction, installers are instructed to verify wiring of dampers, sensors and the AB bus, then contact MADEL Technical Assistance Service if the fault persists. Regular inspection of damper movement, sensor placement in the return‑air duct and cleanliness of the control box help maintain reliable zoning performance over time.

Key technical data

| Feature | Description |

|---|---|

| Product name | MADEL KCA‑SUB sub‑zone control panel for Zoning System. |

| Application | Zoning of 1–6 branches on ducted HVAC installations (sub‑zone operation). |

| Power supply | 230 VAC supply on dedicated terminals. |

| Zone outputs | Up to 6 motorized dampers, red (+) and black (–) wires, 0.75–1.0 mm² conductors. |

| Communication | RS485 AB bus (A = white, B = blue) for digital thermostats. |

| Sensors | NTC 10 kΩ return‑air temperature probe on NTC terminal. |

| Unit control | Y and G relay contacts to interface with indoor unit controls, on/off and mode. |

| Alarm output | Potential‑free normally open contact, closes in alarm condition. |