CR20-06 A-F-A-E-HQQE

The Grundfos CR20-06 A-F-A-E-HQQE is a vertical multistage centrifugal pump delivering 21 m³/h at 70.4 m head with a 7.5 kW IE3 motor, designed for demanding water boosting and industrial applications.

Its cast‑iron base, stainless‑steel internals and HQQE mechanical seal make it a durable, energy‑efficient solution for process water, HVAC, boiler feed and general pressure boosting systems.

Introduction

In modern industry and building services, stable water pressure is no longer a luxury but a basic requirement. The Grundfos CR20-06 A-F-A-E-HQQE has become one of the quiet workhorses in this field, combining compact vertical design with serious performance for installations where downtime is simply not an option.

Technical profile of the CR20-06

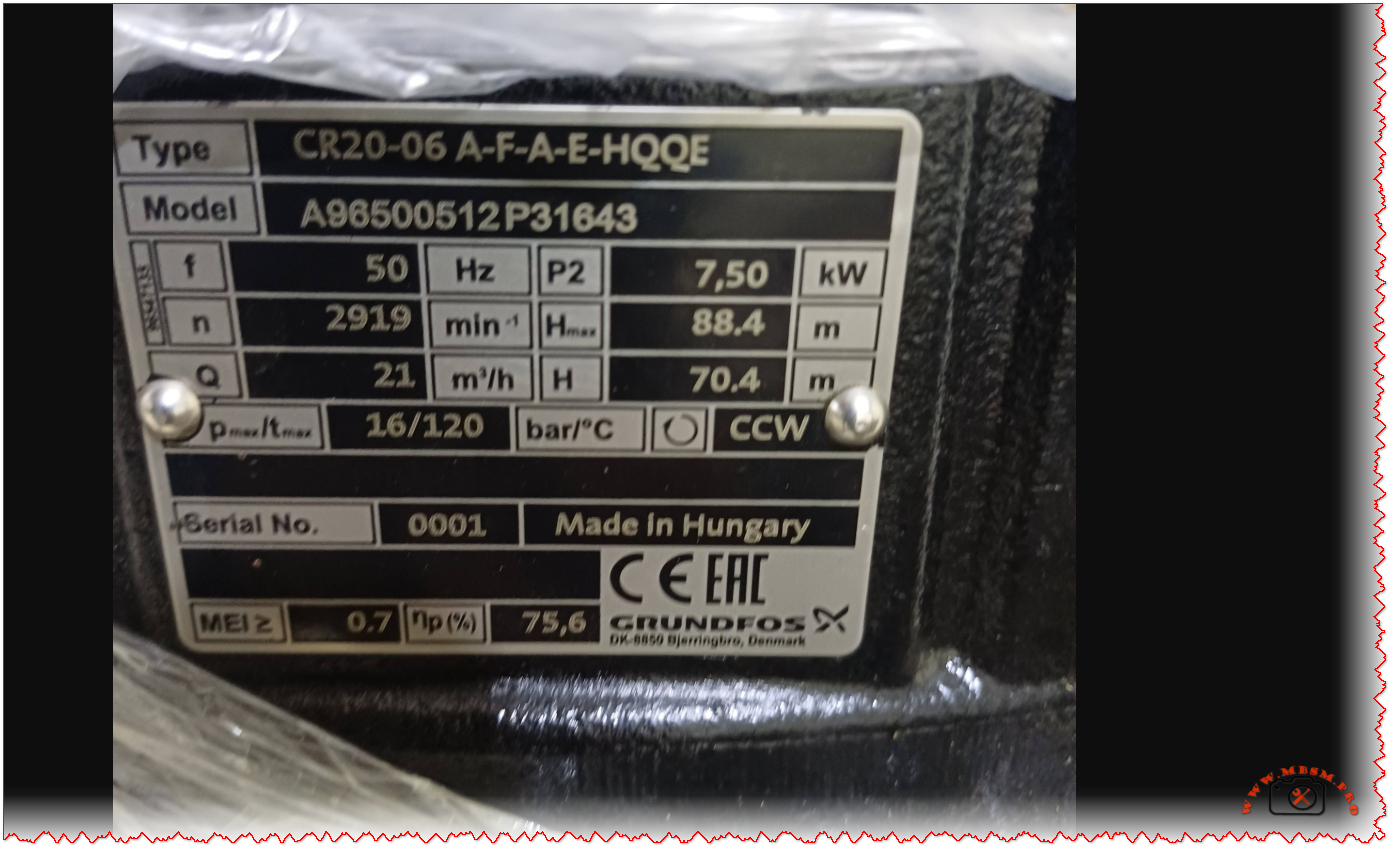

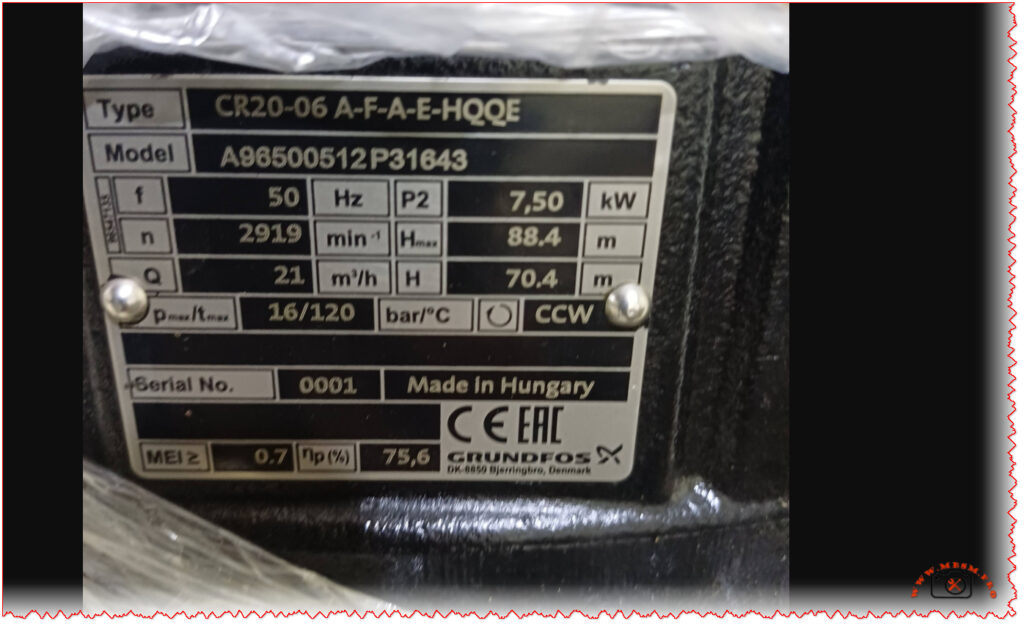

The pump in the photo is clearly identified on its nameplate as a Grundfos CR20-06 A-F-A-E-HQQE with a 7.50 kW motor operating at 50 Hz and about 2919 rpm.

It delivers a nominal flow of 21 m³/h at a rated head of 70.4 m, with a maximum head up to 88.4 m and a maximum operating pressure of 16 bar at liquid temperatures up to 120 °C.

Main nameplate data

| Item | Value |

|---|---|

| Pump type | CR20-06 A-F-A-E-HQQE |

| Rated power P2 | 7.5 kW |

| Frequency / speed | 50 Hz / ≈2919 rpm |

| Rated flow Q | 21 m³/h |

| Rated head H | 70.4 m |

| Maximum head Hmax | 88.4 m |

| Maximum pressure / temp. | 16 bar / 120 °C |

| Shaft seal code | HQQE (single mechanical seal) |

| Pump orientation | Vertical, inline |

| Efficiency (pump) | ≈75.6% (MEI ≥ 0.70) |

The pump uses a vertical, inline layout with suction and discharge on the same level (DN 50 flanged connections, PN 25 rating), simplifying installation in compact plant rooms and on rigid pipe manifolds.

Its IE3 motor (size 132SB) offers motor efficiencies above 90% at typical loads, helping operators reduce long‑term energy costs.

Construction, materials and seal

The CR20-06 belongs to the widely used CR multistage family, where several impellers are stacked in series to build pressure while maintaining moderate flow.

In this specific model, the base and pump head are in cast iron, while all wetted parts such as impellers and chambers are stainless steel AISI 304, providing a good balance between robustness and corrosion resistance for clean water duties.

The HQQE mechanical seal is a single cartridge seal with silicon carbide/silicon carbide faces, EPDM elastomers and a stainless‑steel spring, designed for long service life and easy replacement.

This configuration suits cold and hot water, mildly aggressive media used in HVAC and process plants, and reduces the risk of dry‑running damage during commissioning or transient operating conditions.

Typical applications and operating benefits

With its 21 m³/h at 70.4 m operating point, the CR20-06 is well suited to medium‑pressure boosting in commercial buildings, industrial wash and rinse systems, boiler feed for small to mid‑size boilers, and general process water circulation.

Installers appreciate the inline design, which often allows direct replacement of older horizontal pumps without major changes to the pipework, while plant operators value the quiet operation and low vibration levels of the multistage design.

From an energy perspective, the combination of high hydraulic efficiency and IE3 motor makes this model a strong candidate in projects where life‑cycle cost analysis is required or where regulations demand a minimum efficiency index (MEI ≥ 0.70).

Paired with an external frequency converter, the CR20-06 can be turned into a variable‑speed booster, maintaining constant pressure in domestic water systems, process loops or district cooling circuits while cutting energy consumption during partial‑load operation.

Practical selection notes for engineers

When selecting a CR20-06 for a project, engineers typically start from the required duty point on the pump curve and verify that 21 m³/h at around 70 m head fits the system’s pressure losses, static height and safety margin.

System designers also check NPSH requirements, temperature range from −20 to 120 °C, and maximum ambient temperature up to 60 °C to ensure trouble‑free operation in machinery rooms and outdoor installations.

Because the pump offers a maximum operating pressure of 16 bar with PN 25 flanges, it can be integrated into higher‑pressure manifolds and ring mains, provided that upstream valves, fittings and vessels share compatible ratings.

For users planning future upgrades, the CR range gives a modular platform: additional models and variants can be combined in parallel booster sets, or replaced one‑to‑one if system demand increases.