LG Inverter AC Error Codes: Indoor and Outdoor Unit Professional Guide

LG Inverter AC Error Codes: Indoor and Outdoor Unit Professional Guide

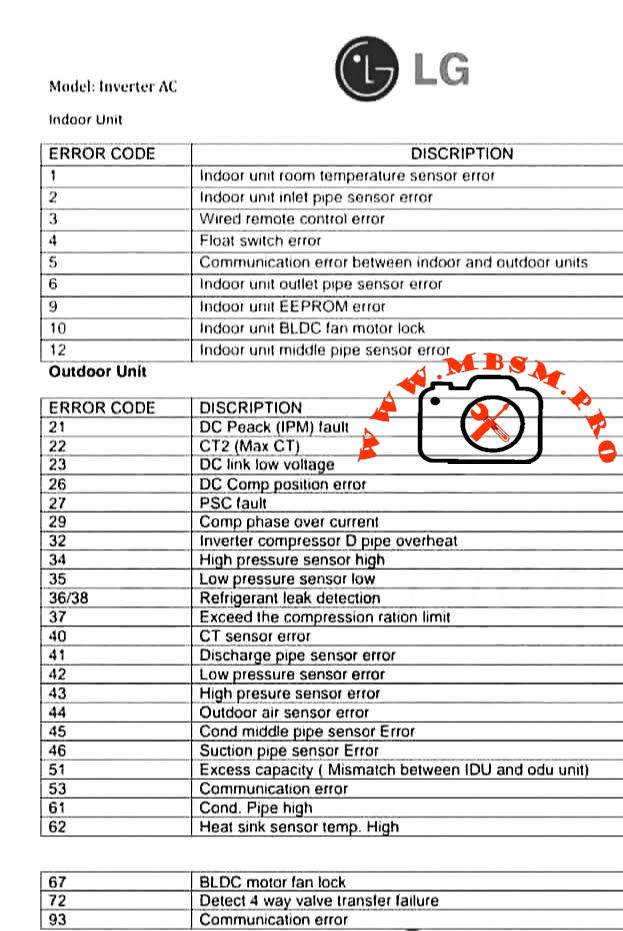

LG inverter air conditioners use numeric error codes to identify sensor faults, communication problems, and inverter failures in both indoor and outdoor units. Understanding these codes helps technicians diagnose issues quickly, reduce downtime, and protect sensitive electronic components.

Indoor Unit Error Codes and Meanings

The indoor unit focuses on temperature sensing, water safety, fan control, and communication with the outdoor inverter PCB. The table below summarizes the most common codes.

Technician conseil: Always confirm sensor resistance vs temperature (for example 8 kΩ at 30 °C and 13 kΩ at 20 °C in many LG thermistors) before replacing the PCB; many “EEPROM” or fan faults are triggered by unstable sensor feedback.

Outdoor Unit Error Codes: Inverter, Power, and Pressure Protection

The outdoor unit handles high‑voltage power electronics, compressor control, and refrigerant protection logic, so most serious faults appear here.

For IPM‑related codes like 21 or 22, LG service bulletins recommend checking gas pressure, pipe length, outdoor fan performance, and compressor winding balance before condemning the inverter PCB.

Comparing LG Inverter Error Logic With Conventional On/Off Systems

Traditional non‑inverter split units often use simple CH codes driven mainly by high‑pressure, low‑pressure, and thermistor faults. LG inverter models add detailed DC link, CT sensor, and IPM protections that can distinguish between power quality issues, compressor mechanical problems, and PCB failures.

| Feature | Conventional on/off split | LG inverter split |

|---|---|---|

| Compressor control | Fixed‑speed relay or contactor | Variable‑speed BLDC with IPM inverter stage. |

| Error detail | Limited (HP/LP, basic sensor) | Full DC bus, IPM, position, and communication diagnostics. |

| Protection behavior | Hard stop, manual reset | Automatic trials, soft restart, and logged protection history in many models. |

This higher granularity allows experienced technicians to pinpoint failures faster but also demands better understanding of power electronics and thermistor networks.

Professional Diagnostic Strategy and Field Consel

From an engineering and service point of view, working with LG inverter codes should follow a structured method rather than trial‑and‑error replacement.

- 1. Confirm the exact model and environment

- Check whether the unit is single‑split, multi‑split, or CAC; some codes change meaning between product families.

- Verify power supply stability, wiring polarity, and grounding before focusing on PCBs or compressors, especially for IPM and CT2 faults.

- 2. Read sensors and currents, not only codes

- Use a multimeter and clamp meter to measure thermistor resistance, compressor current, and DC bus voltage against the service manual tables.

- For sensor errors, compare readings with reference charts (for example resistance vs temperature) to avoid replacing good parts.

- 3. Respect inverter safety

- Wait the recommended discharge time before touching any DC link components; capacitors can retain hazardous voltage even after power off.

- Use insulated tools and avoid bypassing safety switches; overriding a high‑pressure or IPM protection may damage the compressor permanently.

- 4. Compare with factory documentation

- Always check the latest LG error‑code bulletins and service manuals, because some codes (for example 61 or 62) gained additional sub‑causes in new generations.

For professional workshops, building a small internal database of “case histories” linking error codes, environmental conditions, and final solutions can significantly reduce repeated troubleshooting time.

Focus keyphrase (Yoast SEO)

LG inverter AC error codes indoor and outdoor unit sensor, communication, IPM fault and DC peak troubleshooting guide for professional air conditioner technicians

SEO title

Mbsmpro.com, LG Inverter AC, Error Codes 1–93, Indoor and Outdoor Unit, IPM Fault, Sensor Error, Communication Fault, Professional Troubleshooting Guide

Meta description

Detailed LG inverter AC error code guide for indoor and outdoor units, explaining sensor faults, communication errors, IPM and DC peak alarms, with professional diagnostic tips for HVAC technicians and engineers.

Slug

lg-inverter-ac-error-codes-indoor-outdoor-guide

Tags

LG inverter error codes, LG AC fault codes, indoor unit sensor error, outdoor unit IPM fault, DC peak CT2 error, BLDC fan lock, HVAC troubleshooting, inverter air conditioner service, Mbsmgroup, Mbsm.pro, mbsmpro.com, mbsm

Excerpt (first 55 words)

LG inverter air conditioner error codes give technicians a precise window into what is happening inside both indoor and outdoor units. From simple room temperature sensor faults to complex IPM and DC peak alarms, decoding these numbers correctly is critical for fast, safe, and accurate HVAC troubleshooting on modern LG split systems.

10 PDF or catalog links about LG inverter AC error codes and service information

- LG HVAC technical paper “Defining Common Error Codes” for inverter systems (official error explanations and sequences).

- LG air conditioning fault codes sheet for split units, including indoor sensors and compressor protections.

- LG universal split fault code sheet (detailed explanations for codes 21, 22, 26, 29, etc.).

- LG ducted error codes guide covering DC peak, CT2 Max CT, and compressor over‑current protections.

- LG Multi and CAC fault code sheet with advanced guidance for IPM and CT faults.

- LG installation and service manual for inverter units, listing DC link, pressure switch, and inverter position errors.

- LG USA support “Guide to Error Codes” for single and multi‑split systems, with troubleshooting summaries.

- LG global support page “Single / Multi‑Split Air Conditioner Error Codes” including IPM, CT2, EPROM, and communication errors.

- ACErrorCode.com LG inverter AC error code list, useful as a quick field reference.

- Valley Air Conditioning LG air conditioner error code and troubleshooting guide with indoor and outdoor tables.