Coil Rewinding, Universal Motor, 550 W

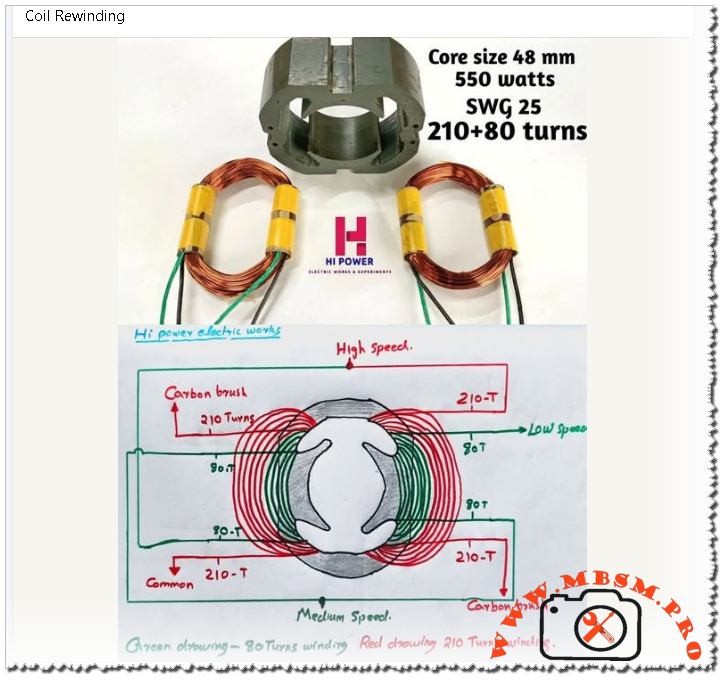

Mbsmpro.com, Coil Rewinding, Universal Motor, 550 W, 48 mm Core, SWG 25, 210+80 Turns, Mixer Grinder, High‑Medium‑Low Speed, Field Coil Winding Diagram

Coil rewinding for small universal motors, such as mixer grinder motors with a 48 mm laminated core and 550‑watt rating, demands precise control of turns, wire gauge, and internal connections. When done correctly, a rewound motor can match or even improve the original performance, while poor technique quickly leads to overheating, sparking, or speed loss.

Technical Overview of 550 W Universal Motor Rewinding

A typical 550‑watt mixer‑grinder uses a two‑pole universal motor with separate field coils and a wound armature, designed for very high speed and strong starting torque. For the 48 mm core shown, common practice is to wind each field with 210 primary turns plus an additional 80 turns using SWG 25 copper wire, giving a combined 210+80 configuration.

From an engineering point of view, keeping the original turns count and SWG is critical, because these define magnetizing current, torque, copper loss, and temperature rise for the motor.

High, Medium, and Low Speed Winding Connections

Multi‑speed mixer grinders often use the same physical coils but connect them differently through the selector switch to change the effective number of active turns and the series/parallel configuration. The diagram referenced for this 550 W motor shows two colored windings per field: red for 210‑turn sections and green for 80‑turn sections, arranged symmetrically around the stator.

Compared with simple single‑speed universal motors, this multi‑tap field arrangement gives finer control of torque and speed without using complex electronic drives, which is ideal for domestic appliances where rugged mechanical selection is preferred.

Engineering Comparison: Universal Motor Rewinding vs Induction Motor Rewinding

Although both tasks are labeled coil rewinding, the engineering approach differs significantly between universal motors and three‑phase induction motors.

Induction motor rewinding relies heavily on slot geometry, phase grouping, and pole pitch, as explained in best‑practice manuals, while universal motor rewinding demands careful routing around the commutator and precise brush alignment for spark‑free operation.

Professional Rewinding Practices and Practical Conseil

Rewinding high‑speed universal motors for appliances requires both electrical knowledge and good workshop discipline. Some key consel for technicians and engineers:

- Copy the original design closely. Measure turns, wire SWG, and connection order before stripping the old winding; best‑practice guides emphasize copying coil pitch, turns, and copper cross‑section to keep performance consistent.

- Keep coil overhang compact. Minimize the length of end turns to reduce I²R loss and keep the motor cool, as recommended for all motor rewinds.

- Balance both sides of the stator. Universal motors are sensitive to magnetic asymmetry; ensure that each pole pair carries identical turns and uses the same direction of winding.

- Secure insulation and impregnation. Use proper slot liners, phase separators, and varnish curing so that coils withstand vibration and high centrifugal forces at full speed.

- Check commutator and brushes. After rewinding, undercut mica, true the commutator, and seat the brushes to avoid heavy sparking during high‑speed operation.

Following these engineering‑grade steps makes the rewound 550‑watt mixer‑grinder motor safe, efficient, and durable in demanding kitchen or workshop environments.

Focus keyphrase (Yoast SEO)

coil rewinding 550 watt universal motor 48 mm core SWG 25 210 plus 80 turns mixer grinder field coil high medium low speed connection diagram

SEO title

Mbsmpro.com, Coil Rewinding, 550 W Universal Motor, 48 mm Core, SWG 25, 210+80 Turns, Mixer Grinder Field Coil, High–Medium–Low Speed

Meta description

Technical guide to rewinding a 550 W universal mixer‑grinder motor with 48 mm core, SWG 25 wire, and 210+80 turn field coils, including speed connections, engineering comparisons, and professional workshop tips.

Slug

coil-rewinding-550w-universal-motor-48mm-core-swg25-210-80-turns

Tags

coil rewinding, universal motor winding, mixer grinder field coil, SWG 25 wire, 210+80 turns, multi speed motor, motor rewinding tips, electric motor repair, Mbsmgroup, Mbsm.pro, mbsmpro.com, mbsm

Excerpt (first 55 words)

Coil rewinding for a 550‑watt universal mixer‑grinder motor with a 48 mm core is more than just replacing burnt copper. The technician must reproduce the original 210+80 turn field coils with SWG 25 wire, respect the high‑medium‑low speed connections, and follow best rewinding practices to keep torque, speed, and temperature under control.

10 PDF or technical resources about motor and coil rewinding

- Mixer‑grinder field coil winding and connection details for 550 W, 48 mm core, including 210+80 turn information (Hi Power Electric Works post and shared diagrams).

- General best‑practice manual “Best Practice in Rewinding Three Phase Induction Motors”, covering stripping, inserting, connecting, and insulating new coils.

- AC motor winding diagrams collection, explaining slot distribution, coil grouping, and phase relationships.

- Technical catalog of coil‑winding machines and accessories used for precision winding of small motors and transformers.

- Leroy‑Somer documentation on winding and unwinding solutions with analog references, focused on tension and speed control in coil production.

- Guide on calculating Standard Wire Gauge (SWG) for motor windings, including formulas linking current, voltage, and wire size.

- General catalog of winding, measuring, and warehouse systems, including manual coil and spool winders.

- PDF manual “Rewinding 3‑Phase Motors” that details mathematical rules for windings, torque, and flux, useful for understanding rewinding principles.

- Technical catalog for IMfinity three‑phase induction motors, providing background on motor design and winding data for comparison.

- Various educational documents and diagrams on AC motor winding available through motor‑winding training PDFs and diagram references similar to the AC motor winding document cited above.