Brass Male Flare Union Fittings for Refrigeration and HVAC Systems

Brass Male Flare Union Fittings for Refrigeration and HVAC Systems

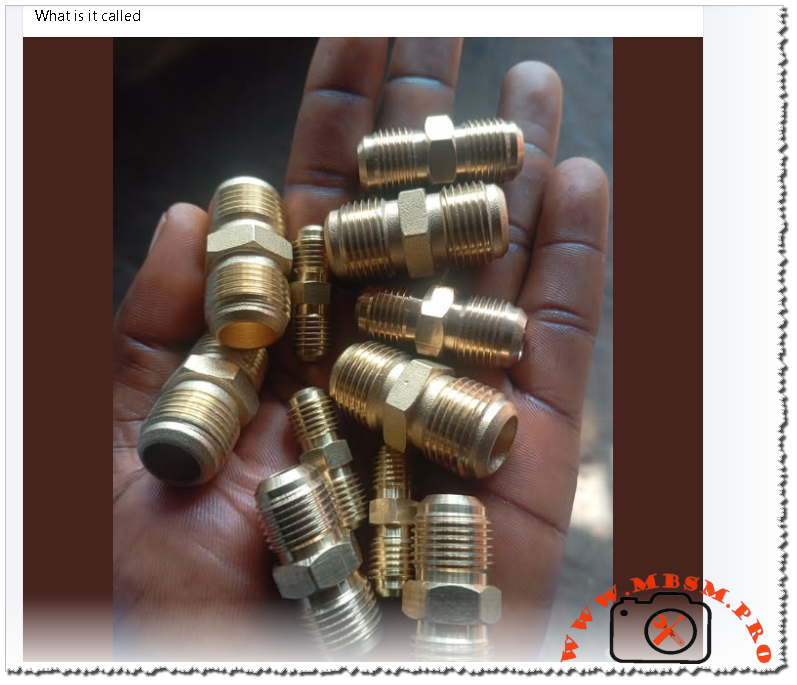

Brass male flare unions are precision fittings used to connect two flared copper or aluminum tubes in refrigeration, air‑conditioning, and gas lines without brazing or welding. These fittings are standard components in professional HVAC installations and service operations.

What These Fittings Are Called

In professional catalogs and engineering documentation, the parts in the image correspond to:

- Brass male‑to‑male flare union

- Brass flare straight union

- Brass flare adapter or half‑union (for versions with a different thread or one closed end)

- SAE 45° brass flare fittings, typically conforming to SAE J512/J513 for refrigeration and gas service.

These fittings are commonly listed with sizes such as 1/4″, 3/8″, or 1/2″ male flare, and are compatible with flared copper, brass, aluminum, or steel tubing in HVAC and refrigeration circuits.

Technical Function and Engineering Advantages

Brass male flare unions provide a mechanical seal between two flared tubes, using metal‑to‑metal contact and the clamping force of the nut. This sealing method avoids filler metals and high temperatures, which is especially useful for:

- Connecting service hoses and gauges to refrigeration lines

- Extending or repairing capillary tubes and liquid lines

- Creating demountable joints in areas where future disassembly is expected

Engineering advantages include:

- Good corrosion resistance in refrigerant and oil environments, thanks to C360/C370 brass alloys.

- Wide working temperature range, typically from −65 °F to +250 °F, suitable for standard HVAC refrigerants.

- Adequate working pressures for common refrigeration tubing; allowable pressure depends on tube material, wall thickness, and outside diameter.

Typical Applications in HVAC/R

These fittings are standard in:

- Refrigeration condensing units and cold rooms using copper linesets

- Split AC systems where service valves and gauge manifolds connect via flare unions

- Gas lines and hydraulic circuits using flared metal tubing, where leak‑tight mechanical joints are required.

They are especially popular in light commercial and domestic refrigeration where technicians want a reversible connection during commissioning, pressure testing, or component replacement.

Comparison With Other HVAC Fittings

Common HVAC Tube Fittings Overview

| Fitting type | Assembly method | Typical use in HVAC/R | Reusability | Need for flame |

|---|---|---|---|---|

| Brass male flare union | Flare and tighten nut | Join two flared copper tubes or extend lines | High | No |

| Solder/brazed coupling | Heat and filler metal | Permanent joints in copper liquid/suction lines | Low | Yes |

| Compression fitting | Ferrule compression | Water lines and some low‑pressure services | Medium | No |

| Flare‑to‑pipe adapter | Flare + NPT/BSP thread | Transition between flared tubing and threaded components | High | No |

Flare unions are preferred where disassembly, leak testing, or component replacement will be routine, while brazed couplings are chosen for long‑term permanent joints in inaccessible locations.

Professional Installation Guidelines and Best Practices

For reliable performance and to meet professional HVAC standards:

- Use properly sized flaring tools with a 45° flare angle compatible with SAE flare fittings.

- Ensure the tubing end is cut square, deburred, and cleaned before flaring to avoid scoring the sealing surface.

- Lubricate threads lightly with refrigeration oil and tighten to the manufacturer’s recommended torque to prevent both under‑tightening (leaks) and over‑tightening (cracked flares).

- Avoid mixing metric and imperial flare sizes or different thread standards; always match the fitting spec to the tubing and equipment rating.

For critical circuits using high‑pressure refrigerants, consult the pressure rating tables in the manufacturer’s catalog and verify compatibility with the working and test pressures of the system.

Practical Tips for Technicians and Engineers

Some additional professional conseils for field and design use:

- When designing new lines, minimize the number of mechanical joints; use flare unions mainly for service points or where components must be removable.

- During retrofits, replace damaged or rounded flare nuts; re‑using deformed nuts increases leak risk even if the tubing flare is renewed.

- In vibration‑prone locations (compressor discharge lines, mobile refrigeration), support the tubing near flare unions with proper clamps to reduce stress on the joint.

- Always perform nitrogen pressure tests and vacuum leak checks after installing or re‑tightening flare unions to confirm system integrity.

Focus Keyphrase for Yoast SEO

Focus keyphrase:

Brass male flare union fitting for refrigeration and HVAC copper tubing connections, SAE 45 degree brass flare connector for air conditioning and gas lines

SEO Title

SEO title:

Brass Male Flare Union Fittings for Refrigeration and HVAC | Mbsm.pro Technical Guide

Meta Description

Meta description:

Professional guide to brass male flare union fittings for refrigeration and HVAC systems, explaining function, applications, engineering specs, and best installation practices for reliable, leak‑tight copper tube connections.

Slug

Slug:

brass-male-flare-union-refrigeration-hvac

Tags

Tags:

Brass male flare union, flare union fitting, refrigeration flare connector, HVAC brass fittings, SAE 45 flare, copper tube union, gas line flare fitting, Mbsmgroup, Mbsm.pro, mbsmpro.com, mbsm

Excerpt (first 55 words)

Brass male flare union fittings are essential components in refrigeration and HVAC systems, providing reliable mechanical connections between flared copper tubes without the need for brazing. These brass flare unions support a wide operating temperature range and are widely used for service connections, line extensions, and removable joints in air‑conditioning and refrigeration installations.

PDF Catalogs and Technical Documents About Brass Flare Fittings

- ROBO‑FIT brass flare fittings catalog (technical data and pressure tables)

- Viking Instrument “Flare Fittings – The World Standard” catalog (HVAC and gas applications)

- Refrigeration Supplies Distributor brass flare fittings section with technical specs (downloadable pages often as PDF from category)

- Refrigerative Supply brass fittings catalog pages (brass flare connectors for HVAC)

- AC Pro Store copper and brass fittings documentation for HVAC, including brass flare fittings

- JB Industries brass fittings documentation for unions and adapters used in refrigeration service

- Mueller Streamline brass flare fittings literature, commonly linked as PDF from distributor pages like Refrigerative Supply

- Fairview Fittings brass flare and pipe adapters technical catalog, accessible via distributor product pages

- AWH refrigeration brass male flare union product data from manufacturer listing on Alibaba (technical attributes and application field HVAC system)

- General brass flare fitting installation and application guides included in many HVAC training documents and manufacturer catalogs referenced above, especially Viking Instrument and ROBO‑FIT.