Secop ES7FT.4 Compressor 1/5 HP R134a Technical Specifications and Replacements

Mbsmpro.com, Compressor, ES7FT.4, 1/5 hp, Secop, Cooling, R134a, 147 W, 1.1 A, 1Ph 220‑240V 50Hz, LBP, RSIR, −35°C to −10°C, Static Cooling

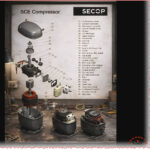

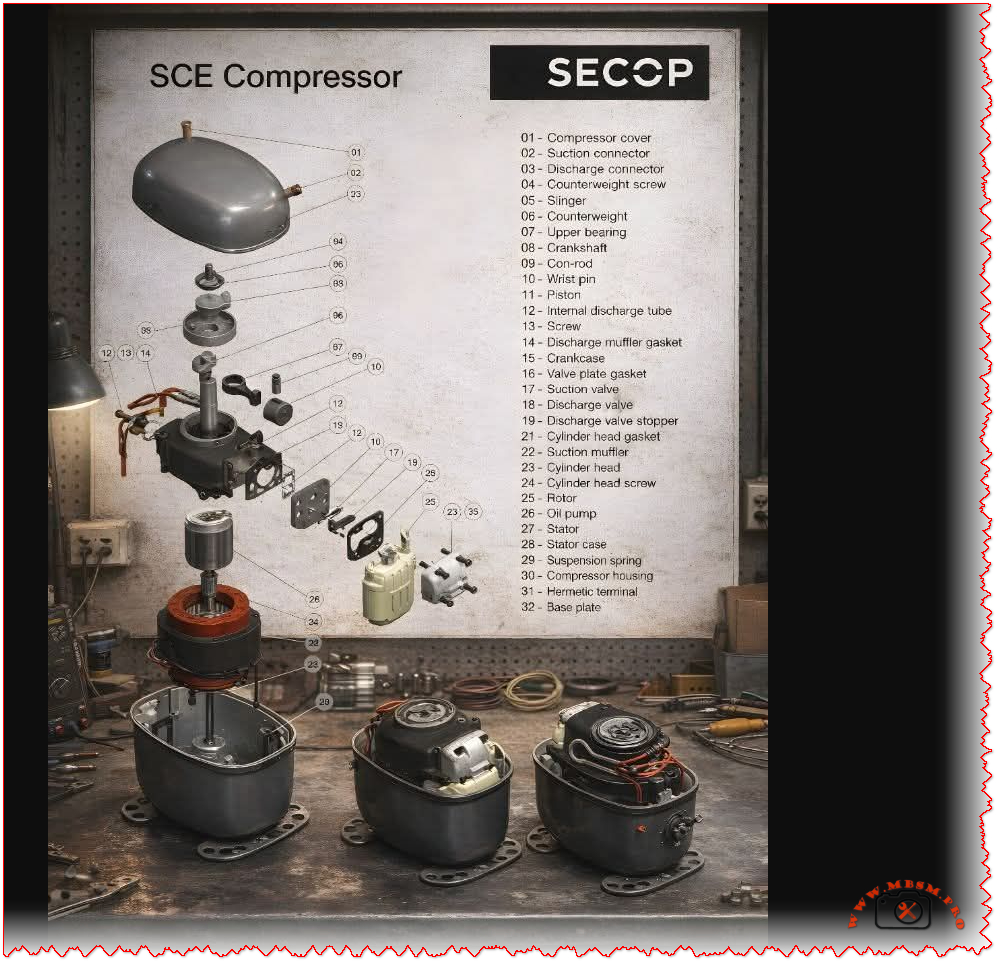

The Secop ES7FT.4 represents a pinnacle of energy-optimized engineering for tropical refrigeration environments. Designed specifically for low back pressure (LBP) applications, this hermetic reciprocating compressor is a reliable workhorse for household refrigerators and small commercial freezers. Operating on R134a refrigerant, it balances thermal efficiency with the robust durability required for high-ambient temperature regions.

Technical Specification Table

| Attribute | Details |

| Model | ES7FT.4 (102G4707) |

| Utilisation | LBP (Low Back Pressure) |

| Domaine | Freezing / Deep Cooling |

| Cooling Wattage at -23.3°C | 147 Watts (CECOMAF) |

| Cubic Feet Capacity | Approx. 7 – 10 cu.ft |

| Liters Capacity | 200 – 300 Liters |

| Kcal/h | 126 kcal/h |

| Oil Type & Quantity | Polyolester (POE) / 180 cm³ |

| Horsepower (HP) | 1/5 HP |

| Refrigerant Type | R134a |

| Power Supply | 220-240V / 50Hz / 1Ph |

| Cooling Capacity BTU | 502 BTU/h |

| Motor Type | RSIR (Resistance Start – Induction Run) |

| Displacement | 5.70 cm³ |

| Winding Material | Copper |

| Pression Charge | Low Pressure Side |

| Capillary Recommendation | 0.031″ or 0.8mm (application dependent) |

| Appliance Type | Domestic Fridge, Chest Freezer, Water Dispenser |

| Temperature Function | -35°C to -10°C |

| Cooling System | Static (S) |

| Commercial Class | Semi-Commercial / Residential |

| Amperage (RLA) | 1.1 A |

| LRA (Locked Rotor Amps) | 5.4 A |

| Type of Relay | PTC Starter |

| Capacitor | N/A (RSIR Configuration) |

| Country of Origin | Slovakia |

Efficiency Metrics (COP) & Performance Data

The efficiency of the ES7FT.4 is measured by its Coefficient of Performance (COP). Below is the performance breakdown at various evaporating temperatures (Condensing Temp at +55°C).

| Evaporating Temp (°C) | Cooling Capacity (Watts) | Power Consumption (Watts) | COP (W/W) |

| -35 | 71.6 | 107 | 0.67 |

| -30 | 99.5 | 125 | 0.80 |

| -23.3 (Standard) | 147 | 148 | 0.99 |

| -20 | 176 | 160 | 1.10 |

| -15 | 228 | 179 | 1.27 |

| -10 | 290 | 200 | 1.45 |

Comparison with Alternative Models

When comparing the ES7FT.4 to other popular 1/5 HP units, we see distinct differences in displacement and energy draw. For instance, the ZMC GM70AZ offers similar wattage but often utilizes different winding resistances. The Secop ES series is specifically “Energy Optimized,” meaning it prioritizes a lower amperage draw during the long run cycles typical of LBP freezing.

Professional Recommendations & Field Notice

As an expert in the field, I recommend the following for any technician installing the ES7FT.4:

- Vacuum Procedure: Always achieve a vacuum of at least 500 microns. R134a and POE oil are highly hygroscopic; moisture will lead to acid formation and premature motor failure.

- Filter Drier: Replace the filter drier (minimum 15g-20g XH-9) every time the system is opened.

- Start Components: If the compressor fails to start in high-heat environments, ensure the PTC starter is not cracked. These units rely on a clean electrical signal to engage the start winding.

Compressor Replacements (Cross-Reference)

5 Direct Replacements (R134a)

- Embraco: EMT6170Z or EMY70HSC

- Danfoss: TLS7F

- ZMC: GL70AA

- Tecumseh: THG1365Y

- Jiaxipera: ND1111Y

5 Replacements (Alternative Gas – R600a)

Note: Requires complete system flushing and capillary adjustment.

- Secop: TLES7.5KK.3

- Embraco: EMX70CLC

- ACC/Seko: HMK80AA

- Donper: L76CZ1

- Huayi: HYE69Y

Focus Keyphrase: Secop ES7FT.4 Compressor 1/5 HP R134a Technical Specifications and Replacements

SEO Title: Secop ES7FT.4 Compressor | 1/5 HP | R134a | Mbsmpro.com Technical Guide

Meta Description: Detailed technical sheet for the Secop ES7FT.4 (102G4707) compressor. Includes 1/5 HP power ratings, R134a gas data, cooling capacity tables, and 10 expert replacement options for refrigeration repair.

Slug: secop-es7ft4-compressor-1-5hp-r134a-specs

Tags: Mbsmgroup, Mbsm.pro, mbsmpro.com, mbsm, Secop, ES7FT.4, 102G4707, 1/5 HP, R134a, LBP Compressor, Refrigerator Repair, EMT6170Z, TLS7F, GL70AA, THG1365Y, ND1111Y, TLES7.5KK.3

Excerpt: The Secop ES7FT.4 is a high-efficiency 1/5 HP hermetic compressor engineered for R134a LBP applications. With a displacement of 5.70 cm³ and a cooling capacity of 147W at -23.3°C, it is an ideal choice for tropical refrigeration. This guide provides full technical data, COP metrics, and professional replacement cross-references for HVAC technicians.