Huayi HYB60MGU Compressor 1/7 HP R600a LBP

Focus keyphrase: Huayi HYB60MGU Compressor 1/7 HP R600a LBP Technical Specifications Wiring Diagram and Professional Replacement Guide for Domestic Refrigeration Systems

SEO Title: Mbsmpro.com, Compressor, Huayi, HYB60MGU, 1/7 hp, R600a, 110 W, 0.55 A, 1Ph 220-240V 50Hz, LBP, RSIR, -35°C to -10°C, cooling or freezing

Meta Description: Technical datasheet for the Huayi HYB60MGU compressor. Explore its 1/7 HP capacity, R600a efficiency, electrical wiring schemas, and professional cross-reference replacements.

Slug: huayi-hyb60mgu-compressor-r600a-1-7hp-specs

Tags: Mbsmgroup, Mbsm.pro, mbsmpro.com, mbsm, Huayi, HYB60MGU, R600a, 1/7 HP, LBP, Compressor Replacement, EMT45HDR, TLES5.7KK.3, T1112Y, A60CY, ETA60, GL60AA, EMI45HER, TLS5F, B30H

Excerpt: The Huayi HYB60MGU is a high-efficiency hermetic reciprocating compressor specifically engineered for Low Back Pressure (LBP) applications. Operating on the eco-friendly R600a refrigerant, this 1/7 HP unit is a primary component in modern household refrigerators. This guide provides an in-depth technical analysis, electrical wiring configurations, and reliable replacement alternatives for field engineers.

The Engineering Behind the Huayi HYB60MGU: A Technical Standard in R600a Cooling

In the contemporary landscape of domestic refrigeration, the Huayi HYB60MGU represents a cornerstone of energy-efficient design. As a professional who has spent years troubleshooting and installing these units, it is clear that Huayi has optimized the HYB series to meet the rigorous European and international standards for low-temperature performance.

This compressor is a hermetic reciprocating type, designed for Low Back Pressure (LBP) cycles. Its integration of R600a (isobutane) not only aligns with global environmental mandates but also provides superior thermodynamic efficiency compared to legacy R134a systems. For technicians, understanding the mechanical and electrical nuances of the HYB60MGU is essential for ensuring system longevity.

Technical Data Sheet: Huayi HYB60MGU

| Feature | Specification |

| Model | HYB60MGU |

| Utilisation (mbp/hbp/lbp) | LBP (Low Back Pressure) |

| Domaine (Freezing/Cooling) | Domestic Refrigerators / Freezers |

| Oil Type and Quantity | Mineral Oil / 180 ml |

| Horsepower (HP) | 1/7 HP |

| Refrigerant Type | R600a (Isobutane) |

| Power Supply | 220-240VAC / 50Hz / 1 Phase |

| Cooling Capacity BTU | 375 BTU/h (approx. 110 Watts) |

| Motor Type | RSIR (Resistive Start – Inductive Run) |

| Displacement | 6.0 cm³ |

| Winding Material | High-Grade Copper |

| Pression Charge | 0.5 to 1.2 Bar (Standard LBP operation) |

| Capillary Recommendation | 0.026″ – 0.028″ ID (Varies by cabinet) |

| Application Range | -35°C to -10°C |

| Cooling System | Static (Natural convection) |

| Commercial Classification | Residential / Household |

| Amperage (Running) | 0.55 A – 0.7 A |

| LRA (Locked Rotor Amperage) | 4.8 A |

| Type of Relay | PTC (Positive Temperature Coefficient) |

| Capacitor Requirement | None (RSIR Configuration) |

Electrical Wiring Schema (RSIR Configuration)

The terminal housing of the Huayi HYB60MGU follows a standard triangular pin configuration which is critical for proper startup and protection.

Schema Description:

- Common (C): The apex pin. This pin connects to the Thermal Overload Protector (OLP), which monitors the motor temperature and current draw.

- Start (S): The pin usually on the right side. It is momentarily energized by the PTC relay to initiate rotation.

- Main/Run (M): The pin on the left side. This winding remains energized throughout the operation of the compressor.

Wiring Logic:

Line (Hot) -> Overload Protector -> Common Pin

Neutral -> PTC Relay -> Main Pin & Start Pin

Engineering Note: Always verify the resistance between C-S and C-M. The sum of these two measurements should roughly equal the resistance across S-M. Any significant deviation indicates a winding fault.

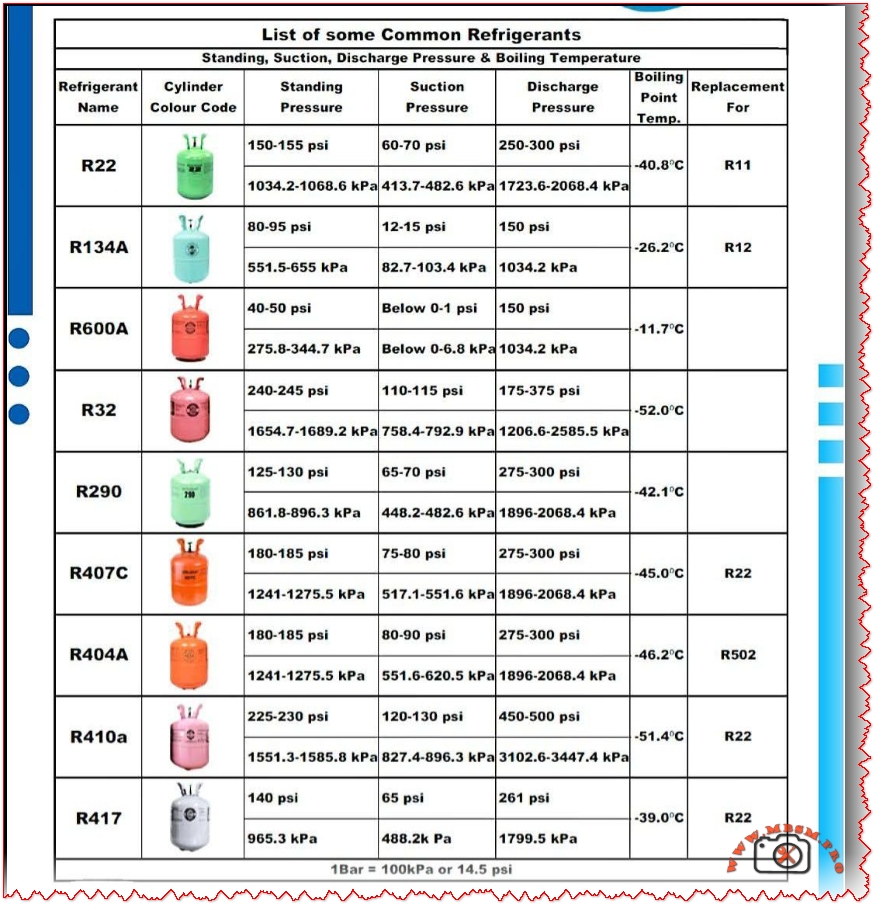

Comparative Efficiency: R600a vs. R134a Models

When evaluating the HYB60MGU, it is helpful to compare it against similarly rated R134a compressors to understand the benefits of the modern R600a cycle.

| Metric | Huayi HYB60MGU (R600a) | Standard 1/7 HP (R134a) |

| Operating Pressure | Low / Vacuum | High Positive |

| Displacement | 6.0 cm³ | 4.5 cm³ |

| Energy Consumption | Low (High COP) | Moderate |

| Environment | GWP < 3 (Eco-friendly) | GWP 1430 (Global Warming) |

Professional Replacement Cross-Reference

In repair scenarios where the exact Huayi model is unavailable, these alternatives provide the same cooling capacity and displacement.

5 Replacements in R600a (Same Gas):

- Embraco: EMT45HDR (High-reliability alternative)

- Secop (Danfoss): TLES5.7KK.3 (Common European replacement)

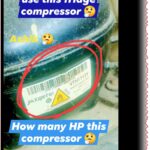

- Jiaxipera: T1112Y (Found in many Beko/Haier units)

- Donper: A60CY

- Wanbao: ETA60

5 Replacements in R134a (Conversion Required):

Note: Converting from R600a to R134a requires a full system flush and capillary resizing.

- Zem: GL60AA

- Embraco: EMI 45HER

- Secop: TLS5F

- Huayi: B30H

- Cubigel: GL60AA

Field Engineering Advice and Notices

- Vacuuming Procedure: Because R600a systems operate at very low pressures, moisture is a catastrophic contaminant. Always pull a vacuum down to at least 200 microns before charging.

- Charging by Weight: R600a is highly sensitive to overcharging. Always use a digital scale and charge precisely to the manufacturer’s specification (usually 40-60 grams). Do not charge by pressure.

- Flammability Safety: R600a is isobutane. Ensure no open flames are nearby during charging or discharging. Use “Lokring” cold connections if you are not in a controlled, ventilated environment for brazing.

- Overload Protection: If the compressor “clicks” but fails to start, check the PTC relay first. These components are prone to cracking due to heat cycles.

Conclusion and Professional Benefit

The Huayi HYB60MGU is a resilient unit that, when maintained correctly, offers years of silent and efficient operation. Its low running amperage makes it an ideal choice for off-grid or solar-powered refrigeration setups where energy conservation is paramount. For the service technician, its standard footprint and predictable electrical behavior make it a preferred model in the field.