Huayi HYE55YL63 and ZMC EGM60AF

Mbsmpro.com, Compressor, HYE55YL63, EGM60AF, 1/5 hp, Huayi, ZMC, Cooling, R134a, 220-240V 50Hz, Kiriazi 14 Feet

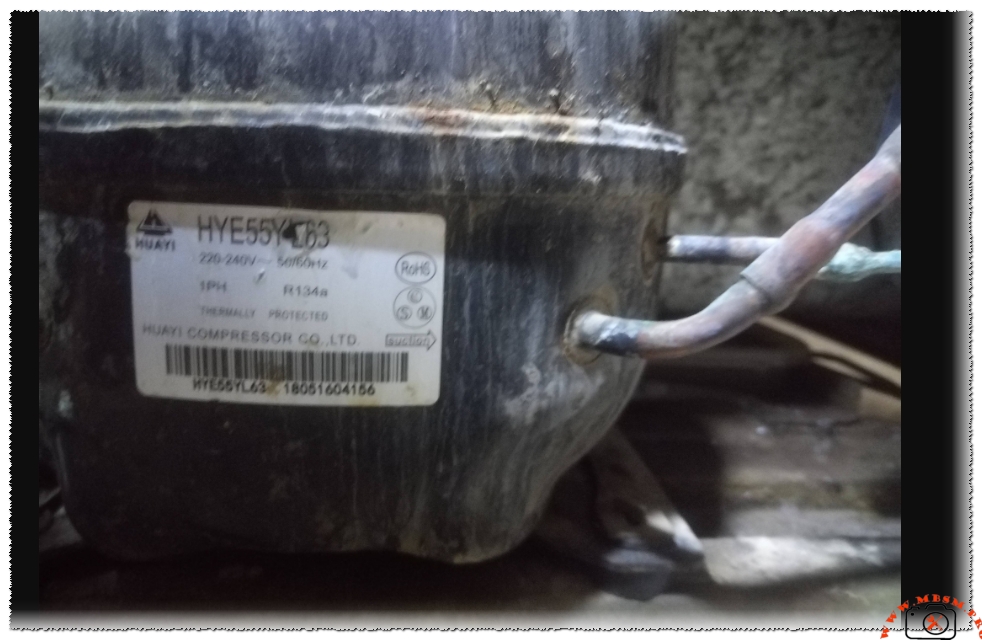

In the demanding world of domestic refrigeration, the choice of a compressor determines the longevity and efficiency of the appliance. Two of the most prominent contenders for the 14-foot Kiriazi and similar medium-sized refrigerators are the Huayi HYE55YL63 and the ZMC EGM60AF. Both are engineered for Low Back Pressure (LBP) applications using R134a gas, but they offer distinct technical nuances that every field technician and engineer should understand.

The Huayi HYE55YL63 is a compact powerhouse with a 5.5cc displacement, optimized for balanced energy consumption. In contrast, the ZMC EGM60AF is often viewed as a slightly more robust alternative, providing a higher cooling capacity and a larger oil reservoir, which can be advantageous in high-ambient temperature environments. Understanding the intersection of these two models is essential for achieving “first-time-right” repairs.

Comprehensive Technical Comparison Table

| Feature | Huayi HYE55YL63 | ZMC EGM60AF |

| Model | HYE55YL63 | EGM60AF |

| Utilisation (LBP) | LBP (Low Back Pressure) | LBP (Low Back Pressure) |

| Horsepower (HP) | 1/5 HP | 1/5 HP (High Efficiency) |

| Refrigerant Type | R134a | R134a |

| Cooling Capacity (-23.3°C) | 155 W (529 BTU/h) | 182 W (621 BTU/h) |

| Displacement | 5.5 cm³ | 6.0 cm³ |

| Oil Type and Quantity | POE / 200 cm³ | Ester / 270 cm³ |

| Motor Type | RSCR | RSIR / RSCR |

| Power Supply | 220-240V / 50Hz | 220-240V / 50Hz |

| LRA (Locked Rotor Amps) | 6.5 A | 11.72 A |

| Weight | 7.9 kg | 8.58 kg |

| Winding Material | Copper | Copper |

Performance Dynamics: Why the EGM60AF Packs a Punch

While both compressors are rated at 1/5 HP, the ZMC EGM60AF features a larger cylinder volume of 6.0cc compared to the 5.5cc of the Huayi model. This translates directly into a higher mass flow of refrigerant.

Key Differences in Field Performance:

- Pull-Down Time: The EGM60AF typically achieves the set-point temperature faster in a 14-foot cabinet due to its higher BTU/h output.

- Thermal Stability: With a 270 cm³ oil charge, the ZMC model offers superior lubrication and cooling for the internal mechanical parts, making it more resilient during long run cycles in summer.

- Efficiency: The Huayi HYE55YL63 often runs at a lower amperage (approx. 0.7A) compared to the EGM60AF, making it the preferred choice for energy-sensitive applications where a lighter load is sufficient.

Compressor Cross-Reference & Replacement Guide

For professionals looking to swap these units, the following models provide compatible cooling curves and physical footprints.

Top 5 Replacements (R134a Gas)

- Embraco: EMT55HLP (1/5 HP – Standard)

- Secop / Danfoss: TLES5.7FT.3 (High efficiency)

- Jiaxipera: N1112GZ (Standard Chinese replacement)

- Cubigel: GL60AA (Direct equivalent to EGM60AF)

- Tecumseh: THB1350YS (Reliable performance)

Top 5 Replacements (Alternative R600a Gas)

Important: Only use these if converting the entire system including capillary and dryer.

- Huayi: HYE60MT

- Embraco: EMX55CLC

- ZMC: EGL60AF (R600a version)

- Secop: TLES5.7KK.3

- Donper: S65CY

Expert Recommendations for the Field

As a field engineer who has handled hundreds of Kiriazi 14-foot units, I strongly advise the following during installation:

- Capillary Matching: If upgrading from a 5.5cc to a 6.0cc compressor, ensure your capillary tube is not restricted. A slight increase in capacity may lead to higher discharge pressures if the condenser is not kept clean.

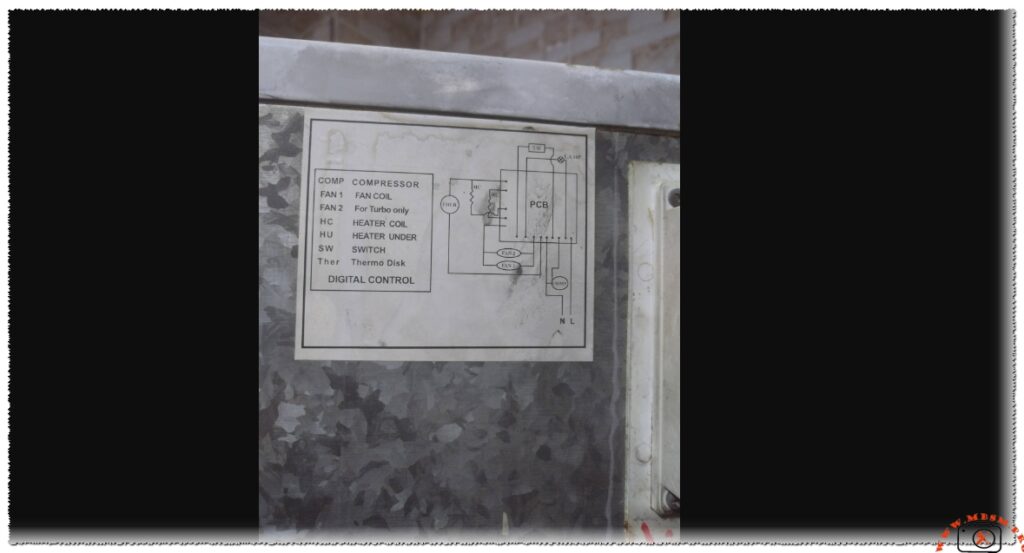

- Capacitor Utility: The Huayi model performs best with a 3µF to 5µF run capacitor. This stabilizes the motor torque and protects the windings from “stalling” during hot restarts.

- The Vacuum Rule: R134a systems are highly sensitive to moisture. Always pull a vacuum below 500 microns to prevent the POE/Ester oil from turning acidic, which will eventually eat through the copper windings.

Focus Keyphrase: Huayi HYE55YL63 vs ZMC EGM60AF Compressor Review

SEO Title: Huayi HYE55YL63 vs ZMC EGM60AF: 1/5 HP Compressor Technical Battle

Meta Description: Compare technical specs of Huayi HYE55YL63 and ZMC EGM60AF compressors. Find cooling capacity, displacement, and the best choice for Kiriazi 14-foot refrigerators.

Slug: hye55yl63-vs-egm60af-compressor-comparison

Tags: Mbsmgroup, Mbsm.pro, mbsmpro.com, mbsm, Huayi, HYE55YL63, ZMC, EGM60AF, Compressor, R134a, 1/5 HP, Kiriazi 14ft, Embraco EMT55HLP, Secop TLES5.7FT.3, Jiaxipera N1112GZ, Refrigerator Repair, LBP.

Excerpt: The Huayi HYE55YL63 and ZMC EGM60AF are two industry-standard 1/5 HP compressors used in domestic refrigerators. While both utilize R134a refrigerant, they differ in displacement and oil capacity. This technical review compares their performance curves and cooling capacities to help technicians select the ideal replacement for Kiriazi and other 14-foot refrigerators.