LG MA57LBJG Compressor 1/6 HP R134a LBP Technical Specifications and Replacements

Mbsm.pro, Compressor, MA57LBJG, 1/6 hp, LG, Cooling, R134a, 160 W, 1.2 A, 1Ph 220-240V 50Hz, LBP, RSIR, -35°C to -10°C, Freezing

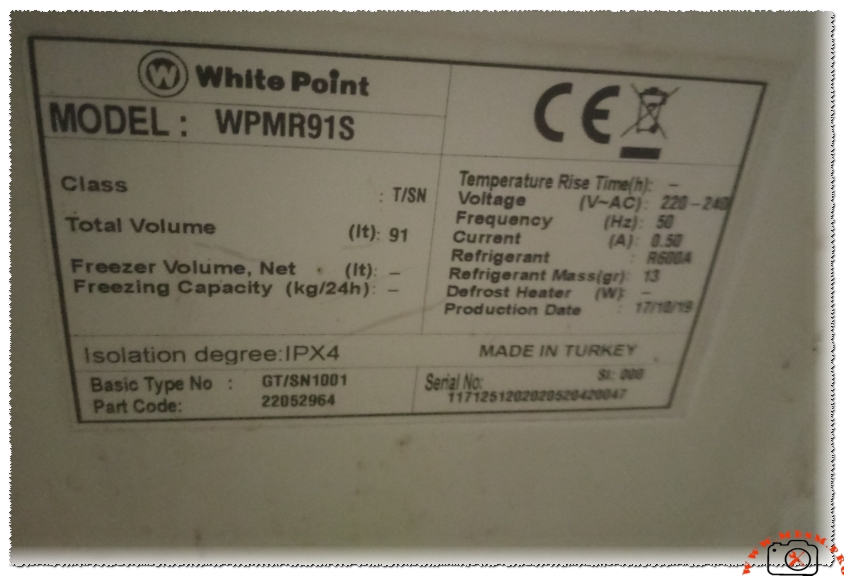

The LG MA57LBJG is a staple in the refrigeration world, specifically engineered for low back pressure (LBP) applications. As a technician or engineer, you recognize this model by its robust build and reliability in domestic cooling. Operating on R134a refrigerant, it balances efficiency with a compact frame, making it a go-to choice for household freezers and large refrigerators.

Technical Specifications Table

| Feature | Specification Details |

| Model | MA57LBJG |

| Utilisation | LBP (Low Back Pressure) |

| Domaine | Freezing / Deep Cooling |

| Cooling Wattage at -23.3°C | 160 W |

| Cubic Feet Capacity | 8 – 11 cu.ft (Depending on insulation) |

| Litres Capacity | 220 – 300 Liters |

| Kcal/h | 138 Kcal/h |

| Oil Type and Quantity | Ester Oil (POE), 180cc |

| Horsepower (HP) | 1/6 HP |

| Refrigerant Type | R134a |

| Power Supply | 220-240V / 50Hz / 1Ph |

| Cooling Capacity BTU | 546 BTU/h |

| Motor Type | RSIR (Resistive Start-Inductive Run) |

| Displacement | 5.7 cc |

| Winding Material | Copper |

| Pression Charge | 0.5 to 1.2 Bar (Low side running) |

| Capillary Recommendation | 0.031″ (0.8mm) x 3 meters (approx) |

| Common Application | LG, Samsung, and Whirlpool Refrigerators |

| Temperature Function | -35°C to -10°C |

| Cooling Method | Natural Cooling (Static) |

| Commercial Status | Residential / Light Commercial |

| Amperage (RLA) | 0.9 A – 1.2 A |

| LRA (Locked Rotor Amps) | 6.5 A |

| Type of Relay | PTC Relay |

| Capacitor | Usually Not Required (RSIR) |

| Origin/Export | Made in China / Exported Globally |

Efficiency Metrics (COP) & Performance

| Evaporating Temp (°C) | Cooling Capacity (Watts) | Power Consumption (Watts) | COP (W/W) |

| -30 | 115 | 105 | 1.10 |

| -25 | 148 | 120 | 1.23 |

| -23.3 | 160 | 128 | 1.25 |

| -20 | 185 | 138 | 1.34 |

| -15 | 230 | 155 | 1.48 |

| -10 | 285 | 175 | 1.63 |

Compressor Replacement Guide

Top 5 Replacements (Same R134a Gas)

- Embraco: EMI60HER / EMT45HDR

- Secop (Danfoss): TLES5.7FT.3

- Tecumseh: THG1358YKS

- Samsung: SD152H-L1UA

- Huayi: HYB60MHU

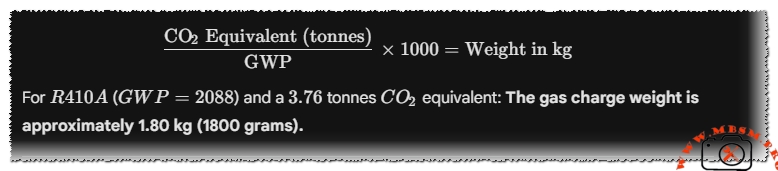

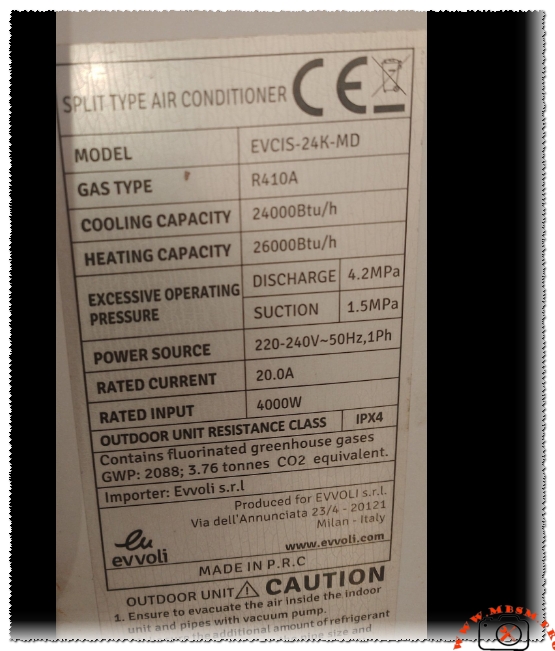

Top 5 Replacements (Alternative Gas – R600a Conversion Required)

- LG: CMA057LHEG

- Embraco: EMX55CLC

- Secop: TLES5.7KK.3

- ACC: HMK80AA

- Donper: S65CY

Note: Replacing R134a with R600a requires a complete system flush, change of oil, and a specific R600a charging procedure due to flammability.

Engineering Insights: Comparison & Benefits

When compared to the slightly more powerful MA62LJJG (1/5 HP), the MA57LBJG offers a higher energy efficiency ratio for mid-sized units. While the 1/5 HP model provides faster pull-down times, the MA57LBJG is optimized for maintaining steady-state freezing temperatures with lower electrical overhead.

Why use this model?

- Copper Windings: Unlike some newer aluminum-wound budget models, the copper internals of the MA57LBJG ensure better thermal conductivity and longer life under high-heat conditions.

- Low Vibration: The internal spring mounting is tuned specifically for domestic environments, ensuring whisper-quiet operation.

Professional Tips for Installation:

Pro Tip: Always replace the filter drier when swapping this compressor. Since it uses POE oil, it is highly hygroscopic (absorbs moisture quickly). Limit the time the system is open to the atmosphere to under 15 minutes.

Focus Keyphrase: LG MA57LBJG Compressor 1/6 HP R134a LBP Technical Specifications and Replacements

SEO Title: Mbsm.pro – MA57LBJG LG Compressor 1/6 HP R134a Data Sheet

Meta Description: Discover the full technical specifications for the LG MA57LBJG compressor. 1/6 HP, R134a, LBP. Includes cooling capacity, COP tables, and 10 compatible replacement models for technicians.

Slug: lg-ma57lbjg-compressor-1-6-hp-r134a-specs

Tags: Mbsmgroup, Mbsm.pro, mbsmpro.com, mbsm, MA57LBJG, LG Compressor, 1/6 HP, R134a, LBP, EMI60HER, TLES5.7FT.3, THG1358YKS, SD152H, HYB60MHU, Refrigeration Repair, Compressor Cross Reference

Excerpt: The LG MA57LBJG is a high-performance 1/6 HP compressor designed for R134a refrigerant in Low Back Pressure (LBP) applications. Ideal for domestic freezers, it delivers 160W of cooling capacity at -23.3°C. This guide provides comprehensive technical data, winding details, and a full cross-reference list for professional refrigeration technicians and engineers.