Scroll Compressor Internal Components Explained

Scroll Compressor Internal Components Explained: Why Design Matters for Reliability & Efficiency

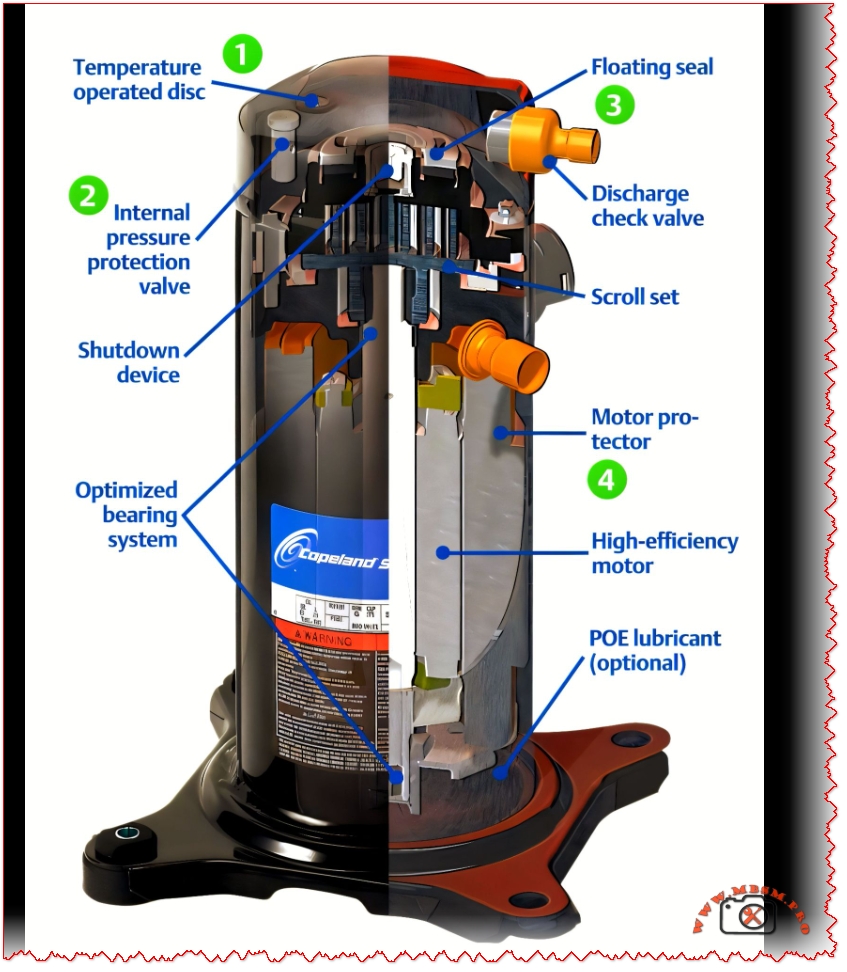

When most technicians open a scroll compressor casing, they’re looking for obvious problems—oil leaks, corrosion, burned-out motor windings. But the real engineering lives in the internal mechanisms you can’t see at first glance: the floating seal that prevents catastrophic vacuum damage, the motor protector that monitors both temperature and amperage, the pressure relief valve that dumps hot gas before the motor fails, and the discharge check valve that prevents high-speed reverse rotation. Understanding these five core components transforms your diagnostic confidence and explains why scroll compressors have outlasted reciprocating designs in millions of air conditioning and refrigeration systems worldwide.

The Floating Seal: The Most Misunderstood Protection Feature

Ask ten HVAC technicians what a floating seal does, and you’ll likely get six different answers. The floating seal’s true function is elegant and critical: it separates the high-pressure discharge side from the low-pressure suction side, and more importantly, it prevents the compressor from drawing into a deep vacuum that would short and destroy the Fusite electrical terminal.

Here’s how it works in practice. When the compressor starts from rest, pressures are equal on both the discharge and suction sides. The orbiting scroll can’t generate compression force without a pressure differential. The floating seal floats on top of the muffler plate, sitting unloaded. As the scroll set spins and begins compressing, internal pressure builds underneath the seal, pushing it up against the top of the muffler plate. Once that pressure differential forms, the seal seals in metal-on-metal contact, creating the separation between high and low side gas. Oil maintains this seal by coating the metal-to-metal interface—not a traditional elastomer gasket.

The vacuum protection aspect is equally important. If a system loses refrigerant charge, or if expansion device blockage prevents suction gas from entering the compressor, the orbiting scroll will keep spinning but won’t find anything to compress. This creates a vacuum on the suction side. Without a floating seal, that vacuum would pull the electrical terminal inward, rupturing it and causing immediate motor failure. The floating seal unloads (separates) when the compression ratio exceeds a critical threshold—typically around 20:1 for ZS and ZF series compressors, and 10:1 for ZB, ZH, ZO, ZP, and ZR series.

When the scrolls are unloaded (separated), the compressor continues to run—it’s spinning without pumping. This is actually a built-in safety feature. Instead of watching the amp meter spike and the motor overheat, the scroll set simply separates, the motor protector monitors rising internal temperature, and the internal overload opens after several minutes, shutting down the compressor before permanent damage occurs.

Common field mistake: Technicians sometimes see a compressor running without building discharge pressure and assume internal failure. In reality, the floating seal has unloaded due to a system issue like low charge, evaporator icing, or a blocked suction line. The real problem isn’t the compressor—it’s upstream.

Motor Protector: Dual Sensing for Maximum Safety

A scroll compressor’s internal motor protector doesn’t work like a traditional overload relay on a reciprocating unit. It’s not just a thermal device sitting in the motor windings. The Copeland motor protector senses both internal shell temperature and amperage simultaneously.

When either temperature OR current exceeds a preset limit, the protector opens an electrical circuit at the terminal box, breaking line voltage and shutting down the compressor. The trip current is typically rated at 103+ amps in a 3-10 second window for overload conditions.

The temperature sensing is particularly clever. The protector monitors discharge plenum temperature—the hot space at the top of the shell where compressed discharge gas collects. When that temperature reaches approximately 250–270°F on most residential and light commercial Copeland models, the protector begins its trip sequence.

Why dual sensing matters: A system with a blocked condenser coil might create high discharge temperatures but normal running current. A system with oil flooding the crankcase might create high current draw with initially normal temperatures. By monitoring both parameters, the motor protector catches problems that single-parameter protection would miss.

Reset behavior is intentional and important. Once tripped, the motor protector requires the compressor to cool down—typically 30 minutes to several hours depending on ambient temperature and how severely the protector was triggered. Technicians who restart a compressor immediately after a motor protector trip often trigger it again within seconds. The cooling-off period allows internal temperature to equalize and motor windings to stabilize, giving an accurate diagnosis of what caused the original trip.

Discharge Check Valve: Silent Guardian Against Destruction

Reciprocating compressors use suction and discharge reed valves inside the piston head—moving parts that open and close thousands of times per minute. Scroll compressors eliminate those moving parts entirely, which is why they’re so quiet. But they still need protection against one specific catastrophe: if a compressor shuts down with high-pressure discharge gas trapped in the shell, and system pressures suddenly drop, that gas will backflow and drive the orbiting scroll in reverse at extremely high speed—potentially 10+ times faster than normal rotation speed.

The discharge check valve prevents this by closing the moment discharge pressure drops below suction pressure. The valve is beautifully simple: a free-floating disc that sits in a valve cage, held open by discharge gas flow during normal operation.

When the compressor stops, discharge flow stops immediately. Without that forward pressure, the disc falls away from its seat (aided by gravity and internal backflow pressure) and closes the discharge port. The design is nearly foolproof because:

- The disc has low surface contact area with the seat, so even if oil-coated, gravity and backflow force overcome adhesion.

- The disc is protected inside a cage that shields it from normal gas pulsations and vibration, preventing chatter.

- It requires zero external maintenance—completely sealed and internal.

The cost is minimal (a stamped metal disc and simple cage), the benefit is enormous (prevention of scroll separation and shaft bearing damage). This is engineering economics at its finest.

Internal Pressure Relief & Temperature Operated Disc: The Redundant Safety Stack

Scroll compressors stack multiple independent safety devices, each with its own trigger point and response. This redundancy prevents the single-point failure that can plague simpler designs.

Internal Pressure Relief Valve (IPR)

The IPR is a spring-loaded valve set to open at a specific differential pressure between discharge and suction. For R-22 applications, this is typically 400 ± 50 psi differential. For R-410A, the threshold is higher at 500–625 psi differential.

When pressure builds beyond this differential (a sign that system pressures are dangerously high), the IPR opens. Instead of venting to the outside, it opens a passage that directs high-pressure gas into the suction side of the compressor, near the motor protector. This sudden injection of hot discharge gas raises shell temperature, triggering the motor protector to open line voltage and shut down the compressor.

Temperature Operated Disc (TOD)

While the IPR responds to pressure, the TOD responds to temperature. The TOD is a bimetallic disc sensitive to discharge gas temperature. On most Copeland ZRK and ZR series compressors, it opens at approximately 270°F.

When discharge temperature climbs (a sign of high compression ratios, lack of cooling, or system inefficiency), the TOD opens and channels hot discharge gas toward the motor protector, causing shutdown.

The redundancy is intentional. A system with a blocked discharge line might trigger the pressure relief. A system with low refrigerant charge and high superheating might trigger the temperature disc. A system with both problems simultaneously will be caught by whichever threshold is reached first.

Scroll Set & Orbiting Design: The Compression Heart

The scroll set consists of two spiral-shaped scrolls—one fixed to the compressor frame, one orbiting around the center. Unlike reciprocating pistons that move linearly, the orbiting scroll makes a circular orbit while maintaining a fixed angular orientation. This continuous motion is what generates the characteristic smoothness of scroll operation.

As the orbiting scroll moves around the fixed scroll, it creates expanding and contracting pockets of refrigerant. Gas enters at the outer edge through the suction port, gets trapped, and as the orbiting scroll continues its orbit, those pockets shrink and move toward the center, compressing the gas. Compressed gas exits through the center discharge port.

The scroll design offers several inherent advantages over reciprocating:

- Continuous compression with no unloading/reloading cycle reduces vibration to one-fifth that of reciprocating units (0.2 bar pulsation vs 2.5 bar).

- Smooth torque delivery with minimal torque ripple, reducing mechanical stress on motors and couplings.

- No suction or discharge valve losses because there are no moving valves inside the scroll set itself—only the discharge check valve external to the set.

- Axial and radial compliance in modern designs allows the scrolls to shift slightly under load, accommodating liquid refrigerant without immediate damage (a capability that’s saved countless systems from catastrophic failure).

Optimized Bearing System: Friction Reduction for Efficiency

One of the most overlooked innovations in modern scroll compressors is bearing design. Conventional scroll compressors used traditional PTFE (Teflon) bush bearings supporting the orbiting scroll journal. Newer designs—particularly in high-speed variable compressors—have moved to outer-type bush bearings made from engineering plastics without back steel layers, combined with female-type eccentric journals.

This seemingly small change delivers significant gains:

- Reduced bearing loads through optimized eccentric journal geometry, lowering friction losses across all operating conditions.

- Lower friction coefficient of the new bearing material vs traditional PTFE, particularly in the hydrodynamic lubrication region where most scroll compressors operate.

- More compact design, with shaft length reduced by ~8% and overall compressor envelope smaller by ~20%.

- Efficiency improvement of 5%+ at rated conditions, with even greater gains at low-speed and high-speed operation.

- Reduced noise by minimizing the excitation moment caused by orbiting scroll centrifugal force and gas forces.

The bearing system also supports higher maximum operating speeds (up to 165Hz expansion in some designs) without bearing fatigue, enabling manufacturers to offer variable-speed scroll compressors that can modulate capacity from 10% to 100%.

High-Efficiency Motor Design & POE Lubricant

Modern Copeland and other premium scroll compressors feature redesigned motor windings optimized for lower copper losses and better heat dissipation. The suction gas returning to the compressor passes through the motor windings, cooling them directly—a passive cooling mechanism that becomes more effective as system load increases.

When system designers specify POE (polyol ester) lubricants for R-410A or HFC refrigerant applications, they’re trading simplicity for efficiency. POE oils are excellent lubricants—superior to mineral oils in cooling capacity and chemical stability. But they’re hygroscopic: they absorb moisture from air at roughly 200 ppm per hour of exposure.

This creates a strict maintenance protocol: system components with POE oil must not remain exposed to ambient air for more than 3 minutes during service. Why? Water contamination in scroll compressor oil leads to acid formation, copper plating, bearing corrosion, and eventual motor failure. Technicians must have evacuation equipment ready, refrigerant recovery systems standing by, and a clear service plan before opening any POE-based system.

Scroll vs. Reciprocating: The Performance Reality

The marketing says scroll compressors are “more efficient.” What does that mean in practical terms?

The efficiency advantage isn’t just a marketing claim—real-world installations show scroll systems reducing annual power consumption by 18% compared to reciprocating at the same capacity. Over a 15-year equipment life at commercial electricity rates, that’s a significant operating cost reduction.

The tradeoff? Scroll compressors cost more upfront and are less forgiving of abuse. A reciprocating compressor can tolerate slight liquid slugging or mild refrigerant overcharge. A scroll compressor will suffer damage faster under identical conditions. This is why proper system design, charge verification, and preventive maintenance are non-negotiable with scroll technology.

Field Diagnostics: What Internal Components Tell You

When a scroll compressor fails or shuts down unexpectedly, the internal components leave diagnostic clues.

High discharge temperature causing shutdown

If your gauges show discharge pressure normal but the compressor shuts down on the motor protector, suspect the temperature operated disc. Check system superheat, confirm the condenser coil is clean, verify proper refrigerant charge, and look for restrictions. The TOD is doing its job—you’ve got an upstream problem.

Low discharge pressure with the compressor running

The floating seal has unloaded. This happens when the compression ratio exceeds the design limit (usually above 10:1). Check for:

- Refrigerant undercharge (most common)

- Evaporator blockage or icing

- Suction filter clogging

- Bad expansion device

Compressor running but no cooling

The orbiting scroll is spinning but the scroll set isn’t compressing. Either the floating seal is unloaded, or more rarely, the scroll set itself has worn beyond tolerance. Let the unit cool, then check whether it pumps during restart.

Discharge check valve failure (reverse rotation damage)

This is catastrophic and irreversible. If a scroll compressor is ever observed rotating backwards (a technician witnesses it at startup, or you see the telltale reverse-rotation noise), the discharge check valve has failed. The orbiting scroll bearing system has been damaged. Replace the compressor—there’s no repair path.

Why Component Design Drives Long-Term Reliability

Every internal component described in this article serves a purpose: the floating seal enables low-torque starting and vacuum protection, the motor protector provides dual-parameter safety, the discharge check valve prevents reverse-rotation destruction, the pressure relief and temperature disc create redundant protection, the bearing system minimizes friction and noise, and the scroll set’s continuous compression delivers efficiency and smoothness.

Manufacturers didn’t add these features by accident. Each one solves a real failure mode observed in thousands of field installations. When you understand why each component exists and what it prevents, you become a better diagnostician and a more confident technician. You stop guessing and start thinking—and that’s how customer satisfaction and system longevity are actually achieved.

Focus Keyphrase (Yoast SEO – 191 characters maximum)

“Scroll compressor internal components floating seal motor protector discharge check valve pressure relief temperature disc explained”

SEO Title (60 characters maximum)

“Scroll Compressor Internal Components & Safety Features Explained”

Meta Description (160 characters maximum)

“Understand scroll compressor internal protection: floating seal, motor protector, discharge check valve, pressure relief, and temperature disc. Why each component matters.”

Slug (Yoast SEO)

scroll-compressor-internal-components-floating-seal

Tags (WordPress)

Scroll compressor, floating seal, motor protector, discharge check valve, internal pressure relief, temperature operated disc, scroll compressor safety, scroll compressor components, Copeland scroll, scroll vs reciprocating, compressor protection, scroll compressor reliability, HVAC compressor, refrigeration compressor, compressor efficiency, Mbsmgroup, Mbsm.pro, mbsmpro.com, mbsm, scroll compressor technology

Excerpt (55 words)

When technicians open a scroll compressor casing, the real engineering lives in internal mechanisms invisible at first glance: the floating seal preventing vacuum damage, the motor protector monitoring temperature and amperage, the pressure relief valve, the discharge check valve preventing reverse rotation, and the optimized bearing system. Understanding these core components transforms your diagnostic confidence.