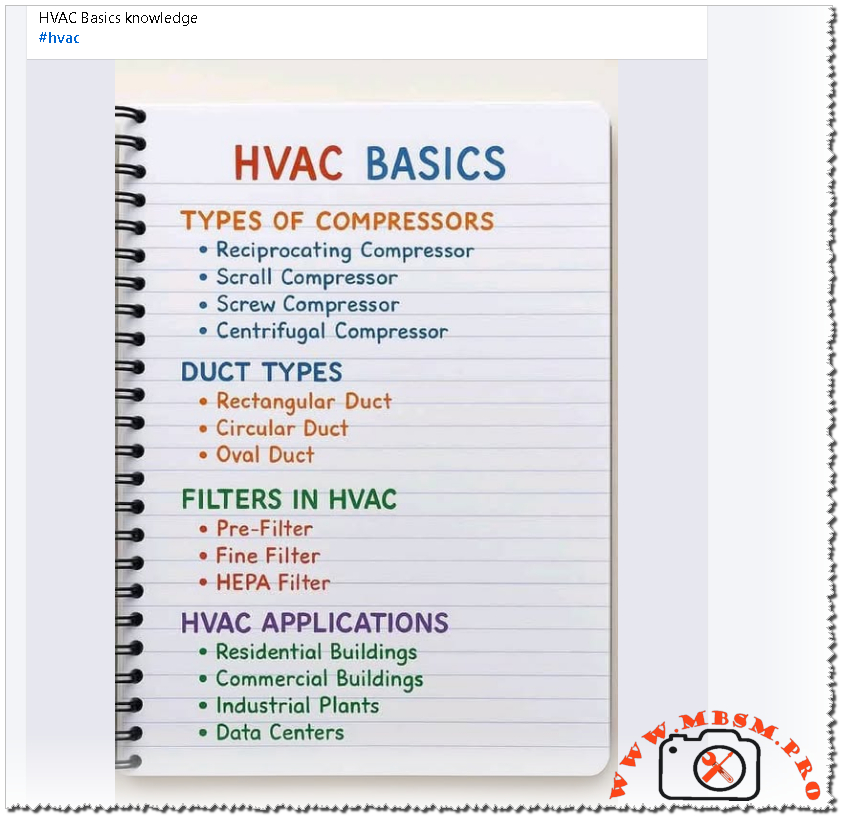

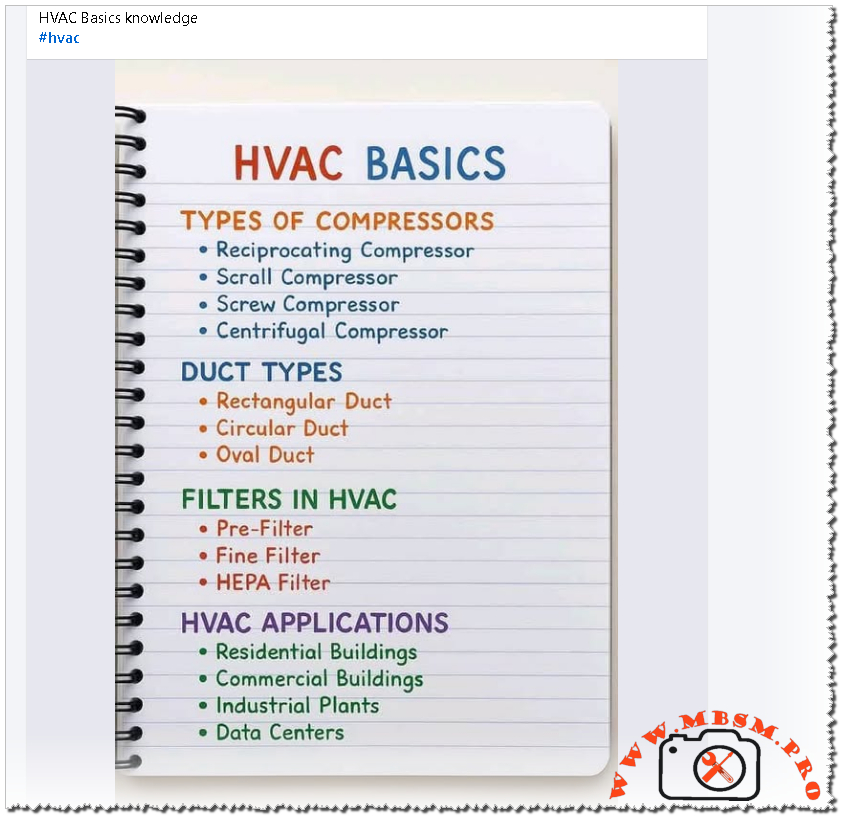

HVAC Basics: Compressors, Ducts, Filters, and Real‑World Applications

HVAC Basics: Compressors, Ducts, Filters, and Real‑World Applications

Understanding HVAC basics is essential for technicians, engineers, and facility managers who want reliable comfort, healthy indoor air, and efficient energy use in every type of building. This guide goes deeper than standard introductions and connects each basic element—compressors, ducts, filters, and applications—to practical field experience and engineering concepts.

Main Types of HVAC Compressors

Compressors are the heart of any refrigeration or air‑conditioning system, raising refrigerant pressure so heat can be rejected outdoors and absorbed indoors. Four main compressor families dominate HVAC and refrigeration:

| Compressor type | Working principle | Typical applications | Key advantages |

|---|---|---|---|

| Reciprocating compressor | Piston moves back and forth in a cylinder, compressing refrigerant in stages. | Small cold rooms, domestic refrigeration, light commercial AC | Simple design, good for high pressure ratios |

| Scroll compressor | Two spiral scrolls; one fixed, one orbiting, progressively traps and compresses gas. | Residential and light commercial split AC, heat pumps | Quiet, high efficiency, fewer moving parts |

| Screw compressor | Two interlocking helical rotors rotate in opposite directions, trapping and compressing gas. | Large chillers, industrial refrigeration, process cooling | Continuous operation, stable capacity control |

| Centrifugal compressor | High‑speed impeller accelerates refrigerant, then diffuser converts velocity to pressure. | Large district cooling plants, high‑rise buildings, industrial HVAC | Very high flow, good efficiency at large capacities |

Engineering insight: choosing a compressor

- Reciprocating vs scroll: Reciprocating units tolerate higher compression ratios and are robust for low‑temperature refrigeration, while scroll compressors deliver smoother, quieter operation for comfort cooling.

- Screw vs centrifugal: Screw compressors are ideal for variable industrial loads and tough conditions, whereas centrifugal units excel when a plant needs very large, steady cooling capacity with clean refrigerant and good water treatment.

For design engineers, selecting a compressor is a trade‑off between capacity range, part‑load efficiency, noise, maintenance strategy, and refrigerant choice.

HVAC Duct Types and Air Distribution

Ductwork acts like the circulatory system of an HVAC installation, moving conditioned air from central equipment to occupied spaces and back again. The main duct geometries are:

Comparison with ductless systems

- Ducted systems distribute air through a network of ducts and are ideal when many zones share common air handling units.

- Ductless systems (like VRF cassettes or mini‑splits) avoid duct losses but put more equipment in occupied spaces; they suit renovations where duct installation is difficult.

Correct sizing, smooth layouts, and sealed joints are crucial engineering tasks; poorly designed ducts can waste 20–30% of fan energy and create comfort complaints.

Filters in HVAC: From Pre‑Filter to HEPA

Air filters protect occupants and equipment by capturing dust, pollen, and fine particulates, and by keeping coils and fans clean. In a typical system, several filter stages can be combined:

| Filter type | Function | Typical efficiency & classification | Main applications |

|---|---|---|---|

| Pre‑filter | Captures coarse dust and fibers, acts as first protection. | G2–G4 or M5 range in EN/ISO standards | Central AC units, fan‑coil units, rooftop units |

| Fine filter | Removes smaller particles, improves indoor air quality. | F7–F9 or ePM1/ePM2.5 classes | Offices, malls, schools, clean industrial spaces |

| HEPA filter | High‑efficiency particle air filtration down to 0.3 µm. | H10–H14, up to >99.995% efficiency | Cleanrooms, hospitals, pharma, high‑tech manufacturing |

Engineering view: value comparison

- Pre‑filters extend the life of fine and HEPA filters by capturing large loads of dust, which reduces lifecycle cost and maintenance frequency.

- Fine filters strike a balance between air quality and pressure drop, suitable where regulations or comfort demand cleaner air but full HEPA is not required.

- HEPA filters are reserved for critical environments; they carry higher pressure drop and require careful design of fans, seals, and housings to avoid bypass leaks.

Engineers should coordinate filter strategy with building use (for example, residential vs hospital), outdoor pollution levels, and standards such as EN ISO 16890 or ASHRAE 52.2.

HVAC Applications Across Building Types

HVAC basics appear in very different configurations depending on the building category and load profile.

Compared with process refrigeration

While comfort HVAC focuses on occupant well‑being and general air quality, industrial process refrigeration may prioritize precise temperature at equipment, sub‑zero conditions, or specific humidity requirements for production lines. In many factories, comfort HVAC and process cooling share chillers or cooling towers but operate under different control strategies and redundancy levels.

Professional Tips and Practical Consel for Technicians

To move from theory to daily field performance, technicians and engineers can follow a few key habits:

- Always look at the system as a chain: compressor, condenser, expansion device, evaporator, ductwork, and controls; diagnosing only one part often hides the real cause.

- When commissioning, verify airflow (CFM or m³/h) as carefully as refrigerant charge; incorrect duct balance can make a perfectly charged system look weak.

- For filters, log pressure drop across each stage and plan replacement based on performance, not just fixed dates; this protects both air quality and fan energy.

- In data centers and sensitive industrial zones, coordinate with IT and production teams to understand critical loads before choosing compressor type, redundancy level, and filtration strategy.

These practices transform simple HVAC “basics” into a robust, engineered system that delivers stable comfort, safety, and reliability throughout the life of the installation.

Focus keyphrase (Yoast SEO)

HVAC basics compressors duct types filters HEPA and HVAC applications in residential commercial industrial buildings and data centers explained for technicians and engineers

SEO title

HVAC Basics, Compressors, Duct Types, Filters, Residential and Industrial Applications | Mbsm.pro Technical Guide

Meta description

Learn HVAC basics with a technical yet practical guide to compressor types, duct systems, air filters from pre‑filter to HEPA, and key HVAC applications in homes, commercial buildings, industry, and data centers.

Slug

hvac-basics-compressors-ducts-filters-applications

Tags

HVAC basics, HVAC compressors, duct types, HVAC filters, HEPA filter, residential HVAC, industrial HVAC, data center cooling, Mbsmgroup, Mbsm.pro, mbsmpro.com, mbsm

Excerpt (first 55 words)

HVAC basics start with understanding how compressors, ducts, and filters work together to move heat and clean air in any building. From reciprocating and scroll compressors to rectangular and circular ducts, each choice affects comfort, energy efficiency, and reliability in residential, commercial, industrial, and data center applications.

10 PDF or catalog links about HVAC basics, compressors, ducts, and filters

- General HVAC BASICS methodology guidebook – RIT (cooling mode, components, airflow).

- TMS Group industrial HVAC systems guide, including ducts, filters, and components (often provided with downloadable technical PDFs).

- AireServ beginner’s guide to HVAC systems, with linked resources covering core components and operation.

- Fieldproxy “Basics of HVAC” resource, describing system elements and maintenance, with references to detailed documents.

- Heavy Equipment College “HVAC Parts and Their Functions” technical overview, listing all major components and roles.

- Gardner Denver knowledge hub on types of air compressors, including reciprocating, scroll, and screw, often linked as downloadable brochures.

- Sullair “Types of Compressors” knowledge document explaining rotary screw, scroll, and centrifugal compressor technology.

- ALP HVAC Filter Systems catalog, covering pre‑filters, fine filters, and HEPA filters with efficiency classes and applications.

- Camfil general ventilation filters catalog, showing bag filters, fine filters, and HEPA‑level products for HVAC applications.

- EU vs ASHRAE filter standards comparison for high‑efficiency and HEPA filtration, explaining classes H10–H14 and mechanisms.