AC vs DC Refrigerator Compressors

Mbsmpro.com, Refrigerator Compressors, AC vs DC, Digital Inverter, Energy Saving, Low Noise, Precise Temperature Control, Home and Commercial Cooling

AC vs DC Refrigerator Compressors: The New Battle Inside Your Fridge

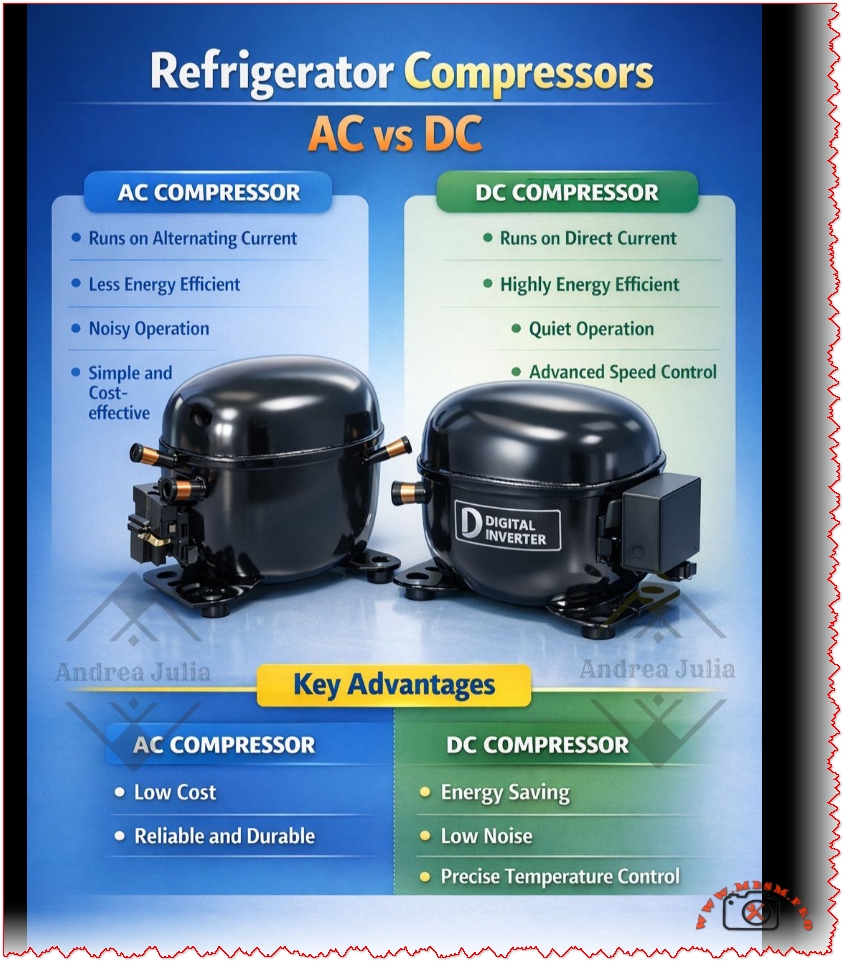

Refrigerator compressors are moving from simple AC motors to sophisticated DC inverter technology that promises lower bills, less noise, and tighter temperature control. DC inverter compressors now dominate premium refrigerators, while classic AC units remain attractive where upfront cost is critical.

Core Principles of AC and DC Compressors

- AC refrigerator compressors use alternating current and usually work ON/OFF at fixed speed; the thermostat starts and stops the motor when cabinet temperature crosses the set point, which wastes energy in frequent restarts.

- DC inverter compressors run on direct current and adjust speed continuously by changing voltage and frequency, matching cooling capacity to real load instead of cycling at full power.

- This variable‑speed strategy cuts start‑up current peaks, improves part‑load efficiency, and keeps evaporator temperature more stable than fixed‑speed AC designs.

Technical Comparison: AC vs DC Compressors

Operating characteristics

- AC compressors behave like a binary switch: either maximum capacity or stopped, which increases mechanical stress and temperature swings inside the refrigerator compartment.

- DC compressors modulate rotation speed; at light load they run slowly, reducing compression ratio and internal losses while still maintaining required suction pressure.

- Inverter control electronics rectify the AC mains, then generate controlled DC power for the brushless motor so the system can follow fine temperature commands from the controller.

Energy and performance

- Tests on household units show DC inverter refrigerator compressors can cut electricity use by around 20–30 % compared with equivalent fixed‑speed AC models, especially in part‑load operation.

- More precise temperature control improves food quality and reduces frost build‑up, which further improves long‑term efficiency by keeping heat‑exchange surfaces cleaner.

Performance Table: AC vs DC Refrigerator Compressors

Economic and Practical Trade‑Offs

- In many markets, the added cost of a DC inverter refrigerator can be recovered in a few years purely through lower electricity bills, especially where tariffs are high or usage is continuous.

- AC compressors remain competitive in low‑cost appliances and in regions with unstable power quality, because they use simpler starting gear and cheaper spare parts.

- For OEMs, copper windings, precision machining, and control electronics are key cost drivers; optimizing these elements can cut compressor manufacturing cost by about 10 % without sacrificing performance.

Application Comparisons Beyond Domestic Refrigeration

1. Solar and mobile refrigeration

- DC compressors powered directly from 12 V or 24 V battery systems avoid inverter losses and are now common in RVs, boats, telecom shelters, and off‑grid vaccine coolers.

- Their compact form factor and high part‑load efficiency make them ideal for portable coolers and mini freezers where every amp‑hour matters.

2. Air conditioning and heat pumps

- In AC and heat‑pump systems, inverter compressors use the same DC modulation principle to deliver faster pull‑down and quieter operation while reducing energy use and vibration.

- Variable‑speed technology combined with economizer or vapor‑injection circuits further boosts heating capacity at low ambient temperature, as seen in modern R410A DC EVI compressors.

- Conventional fixed‑speed hermetic AC compressors still dominate walk‑in coolers and supermarket cases because of their low cost and well‑known service procedures.

- However, new digital inverter and scroll solutions can provide up to 40 % better energy efficiency and noticeably lower greenhouse‑gas emissions compared with legacy constant‑speed compressors.

Extended Specification Table: AC, DC Inverter, and Inverter Scroll

Choosing Between AC and DC Compressors

- For home refrigerators, DC inverter models are now the best choice when long‑term energy savings, low noise, and food quality are priorities, even if initial price is higher.

- For entry‑level appliances or harsh workshop environments, robust AC compressors remain relevant thanks to their simplicity and lower replacement cost.

- In specialized segments such as medical cold chains, telecom shelters, and high‑end commercial cabinets, DC and inverter compressors offer clear advantages in reliability, temperature accuracy, and total cost of ownership.