Stay away from 4 washing machines: Kiriazi, Candy, GMC, White Whale

Mbsmpro.com, Washing Machines, Technical Reliability, LG, Samsung, Bosch, Structural Failures, Kiryazi, Candy, GMC, White Whale

our decision to stay away from these four brands (Kriazi, Candy, GMC, White Whale) may be based on past experiences or technical advice related to the availability of spare parts, the quality of after-sales service, or the lifespan of electronic components.

In the professional appliance sector, choosing a washing machine is an engineering audit, not a simple shopping trip. As a field expert who has dismantled thousands of units and performed rigorous stress tests on drive systems, I look beyond the digital displays to the mechanical heart of the machine: the drum bearings, the motor windings, and the electrolytic capacitors on the control board.

Technical data from the field indicates a significant divergence in quality. While some brands focus on high-turnover consumer goods, others invest in Structural Integrity. If you are being advised to “stay away” from Kiryazi, Candy, GMC, and White Whale, it is not a matter of brand bias—it is a matter of documented mechanical fatigue and specialized component scarcity.

Technical Breakdown: Identifying the Structural Bottlenecks

When an appliance fails, it is usually due to a “weakest link” in its design. Here is the professional technical breakdown of why these four brands often face professional criticism from repair engineers:

- Kiryazi (Structural Oxidation): The primary issue lies in the galvanization process of the outer cabinet. In many models, the steel gauge is insufficient, leading to premature rust around the detergent drawer and base, which eventually compromises the machine’s balance during high-RPM cycles.

- Candy (Electronic Volatility): Candy machines often feature highly sophisticated integrated circuits. However, the PCB (Printed Circuit Board) lacks robust thermal shielding. In environments with fluctuating voltage, the microprocessor is prone to “logic hanging” or total failure.

- GMC (Mechanical Friction): Many GMC models rely on traditional Universal Brush Motors. These motors generate significant carbon dust and heat, leading to shorter lifespans for the drive belt and much higher decibel levels during the spin cycle.

- White Whale (Component Inconsistency): The “Spider” assembly (the three-arm support for the drum) in these units is frequently made of a low-grade Zinc-Aluminum alloy. This material reacts chemically with liquid detergents, leading to “pitting corrosion” and eventual drum detachment.

Engineering Comparison: High-Tier vs. Standard Tier

To make an informed decision, we must compare the Material Science and Drive Systems of industry leaders against standard budget models.

| Technical Component | Standard Group (Avoid) | LG (Direct Drive) | Samsung (Inverter) | Bosch (Series 6/8) |

|---|---|---|---|---|

| Motor Tech | Universal Carbon Brush | Brushless DC (BLDC) | Digital Inverter | EcoSilence Drive |

| Drive Logic | Mechanical Pulley | Direct Coupling | Reinforced Ribbed Belt | High-Torque Belt |

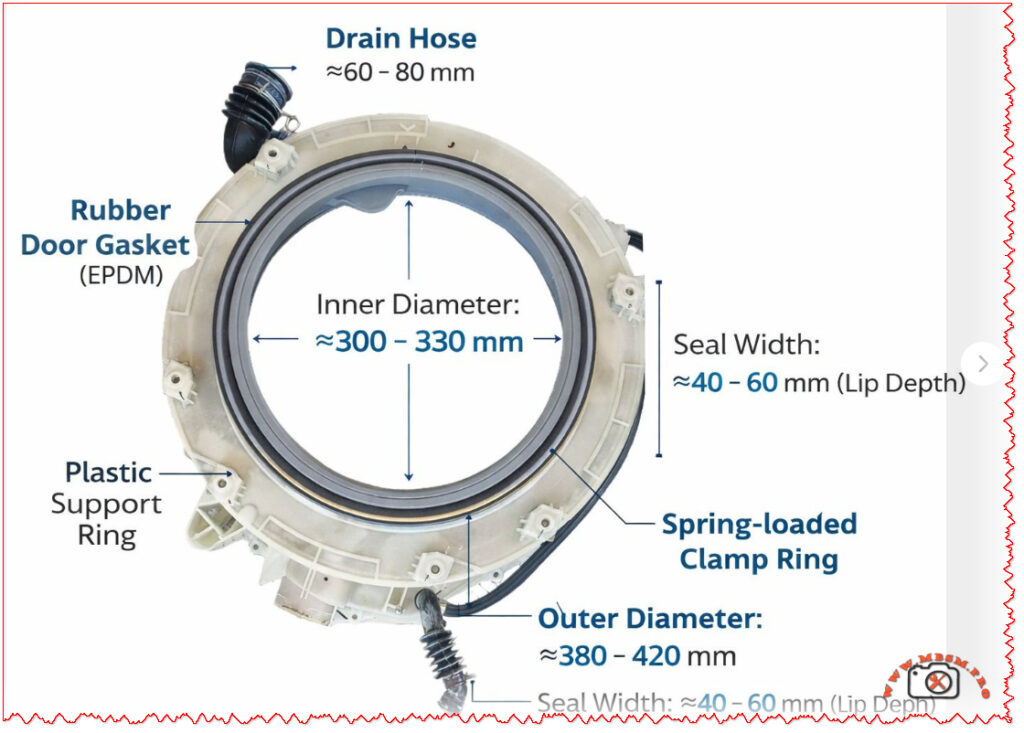

| Bearing Seal | Single Lip | Double-Lip / Viton | High-Temp Synthetic | Industrial Grade |

| PCB Protection | Basic Varnish | Resin Encapsulation | Moisture Shield | Thermal Management |

| Vibration Control | Standard Springs | 6-Motion AI | VRT Plus (Ball Balance) | AntiVibration Walls |

The Inverter Logic: Electronic Schematic of Superiority

For the technician, the shift to Inverter Technology (found in LG, Samsung, and Bosch) is the greatest leap in reliability. Unlike the simple “On/Off” relay logic of older GMC or Kiryazi units, modern systems utilize a Variable Frequency Drive (VFD) logic path:

- Rectification Stage: Incoming AC is converted to stable DC power.

- IGBT Switching: (Insulated Gate Bipolar Transistors) pulse the power to the motor windings.

- Frequency Modulation: By changing the electrical frequency, the machine controls torque and speed with extreme precision, without mechanical stress.

- Result: This eliminates the Carbon Brushes, which are the primary wear-and-tear component in traditional washing machines.

Field Values: Performance Comparison Metrics

| Performance Feature | Budget Brands (Kiryazi/GMC) | Premium Engineering (LG/Bosch) |

|---|---|---|

| Spin Decibels | 76 dB – 82 dB | 48 dB – 54 dB |

| Thermal Cut-out | Frequent (friction-based heat) | Rare (active cooling logic) |

| Drum Balance | Passive (Weight-based) | Active (Sensor-based) |

| Parts Availability | Fragmented / Generic | Serialized / Global |

Professional Councils and Maintenance Protocols

- Advice on Installation: Never place a washing machine on a wooden floor or an unlevel surface. For Bosch and LG units, precision leveling is required to allow the internal accelerometers to calibrate the “Zero-Point” vibration correctly.

- Notice on Detergent: Excessive use of “Soap Powder” causes a buildup known as “Scrud.” In White Whale and Candy models, this acidic sludge accelerates the decay of the drum seal.

- The Benefit of Direct Drive: By removing the belt, LG has eliminated a major friction point, significantly reducing energy loss and increasing the motor’s life expectancy to over a decade.

Final Technical Verdict

The recommendation to avoid Kiryazi, Candy, GMC, and White Whale is based on the Mean Time Between Failures (MTBF) observed in the field. As an engineer, I recommend prioritizing brands that utilize Resin-Encapsulated Electronics and Brushless Motors. LG, Samsung, and Bosch provide the necessary Mechanical Tolerance to handle the stresses of modern laundry requirements.

Focus keyphrase: Technical engineering review of washing machine brands explaining why LG Samsung and Bosch are superior to Kiryazi Candy GMC and White Whale for long-term durability.

SEO title: Mbsmpro.com, Washing Machines, Technical Reliability Review, LG, Samsung, Bosch

Meta description: Expert engineering analysis on washing machine durability. Discover why technicians recommend LG, Samsung, and Bosch over Kiryazi, Candy, GMC, and White Whale for long-term use.

Slug: washing-machine-technical-reliability-lg-samsung-bosch

Tags: Mbsmgroup, Mbsm.pro, mbsmpro.com, mbsm, Washing Machine Repair, LG Direct Drive, Bosch EcoSilence, Samsung Inverter, Appliance Engineering, Inverter Motor Schematic, Drum Bearing Failure.

Excerpt: A washing machine is a long-term engineering investment. From a field technician’s perspective, choosing the right brand depends on mechanical durability and electronic stability. While brands like Kiryazi, Candy, GMC, and White Whale are popular, they often face structural oxidation and PCB failures. This article analyzes why LG, Samsung, and Bosch are technically superior.