The Technician’s Take on the Matsushita QA77C17GAX5

Focus Keyphrase: Matsushita Panasonic QA77C17GAX5 Refrigerator Compressor 1/4 HP R134a Specs and Cross-Reference

SEO Title: Mbsm.pro, Compressor, QA77C17GAX5, 1/4 hp, Matsushita, Cooling, R134a, 180 W, 1.2 A, 1Ph 220-240V 50Hz, LBP, RSIR

Meta Description: Full technical breakdown of the Matsushita QA77C17GAX5 compressor. Learn about its 1/4 HP capacity, R134a requirements, and the best replacement models for fridge repairs.

Slug: matsushita-qa77c17gax5-compressor-specifications-guide

Tags: Mbsmgroup, Mbsm.pro, mbsmpro.com, mbsm, Matsushita, Panasonic, QA77C17GAX5, R134a, 1/4 HP, LBP, Refrigerator Repair, Compressor Replacement, Embraco, Secop, Danfoss, LG, Tecumseh, Fridge Parts

Excerpt: The Matsushita QA77C17GAX5 is a workhorse in the refrigeration world. This 1/4 HP R134a compressor is a go-to for many household fridges and freezers. In this guide, we break down the technical specs, electrical wiring, and the most reliable replacement options to help you get your cooling system back up and running fast.

The Technician’s Take on the Matsushita QA77C17GAX5

When you spend enough time in the field, you start to recognize certain parts that just don’t quit. The Matsushita QA77C17GAX5 is one of those units. Produced by Panasonic, this compressor has been a standard in residential cooling for years. It’s a 1/4 HP unit designed for Low Back Pressure (LBP) applications, meaning it’s built to reach and hold those deep-freeze temperatures.

What makes this model interesting is its balance. It has a 7.7cc displacement, which is a sweet spot for R134a systems. It’s powerful enough for a full-sized family refrigerator but efficient enough that it doesn’t hammer the electric bill. From an engineering perspective, the RSIR motor is simple and reliable—fewer components like capacitors mean fewer things to fail in the heat of summer.

Real-World Performance

I’ve noticed that these compressors handle voltage dips better than many modern counterparts. While some high-efficiency units are sensitive to “dirty” power, the QA77 series is built like a tank. It delivers about 180 Watts of cooling power at standard ASHRAE conditions, making it a versatile choice for a wide range of kitchen appliances.

Complete Technical Data Table

| Data Point | Technical Specification |

| Model | QA77C17GAX5 |

| Utilisation | LBP (Low Back Pressure) |

| Domaine | Freezing / Cooling |

| Oil Type and Quantity | POE (Polyolester) / 230ml |

| Horsepower (HP) | 1/4 HP |

| Refrigerant Type | R134a |

| Power Supply | 220V – 240V / 50Hz / 1 Phase |

| Cooling Capacity | 614 BTU/h (180 Watts) |

| Motor Type | RSIR |

| Displacement | 7.7 cm³ |

| Winding Material | Copper |

| Typical Pressure | Suction: ~1 PSI / Discharge: ~140 PSI |

| Capillary Tube | 0.031″ Internal Diameter |

| Common Usage | Household Fridges, Chest Freezers |

| Temp Range | -35°C to -10°C |

| Fan Requirement | Static Cooling (Natural Convection) |

| Type | Domestic / Light Commercial |

| Amperage | 1.1A to 1.3A |

| LRA (Locked Rotor) | 14.5 Amps |

| Relay Type | PTC |

| Capacitor | None (Standard configuration) |

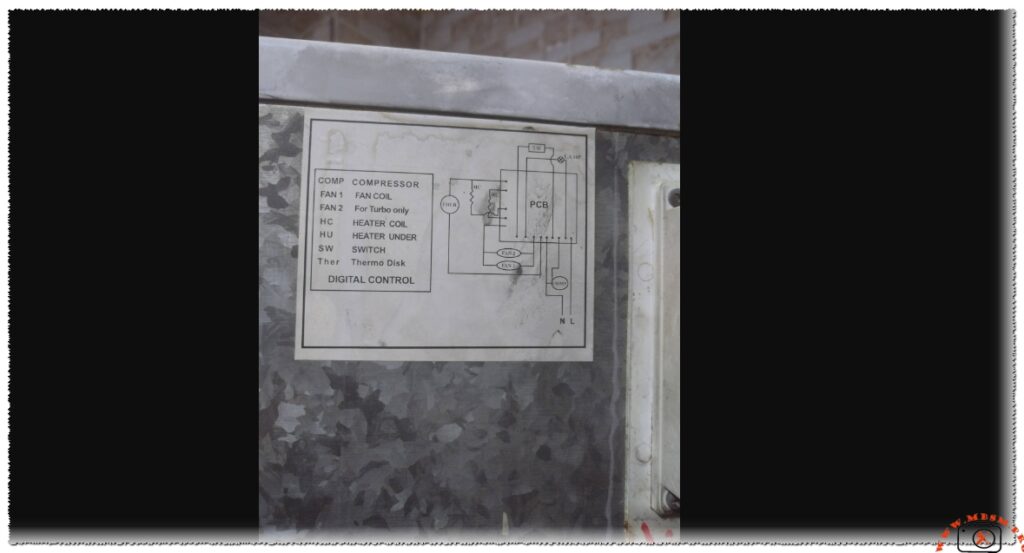

Wiring and Electrical Logic

Working with the electrics on this unit is straightforward. It uses a three-pin terminal setup.

- Top Pin (Common): This is where your Overload Protector (OLP) sits. It’s the safety gate that shuts the compressor down if it gets too hot.

- Bottom Left/Right (Start & Run): The PTC relay slides onto these. When you power it up, the relay gives a quick “kick” to the Start winding and then lets the Run winding take over once the motor is spinning.

Pro Tip: If the compressor won’t start but it’s humming, check the PTC relay first. They often burn out before the motor does. Shake it—if it rattles like broken glass, it’s shot.

How it Compares to Other Brands

| Manufacturer | Competitor Model | Refrigerant | Capacity (Watts) |

| Matsushita | QA77C17GAX5 | R134a | 180 W |

| Embraco | FFI7.5HAK | R134a | 193 W |

| Danfoss/Secop | TLS7FT | R134a | 175 W |

| LG | MA72LCEP | R134a | 185 W |

Compared to the Embraco FFI7.5HAK, the Matsushita is slightly quieter but offers almost the same cooling torque. The Embraco might pull a vacuum a bit faster, but the Matsushita generally has a longer lifespan in high-ambient environments.

Expert Maintenance Notice

- Vacuum is Non-Negotiable: Because this unit uses POE oil, moisture is the enemy. POE oil absorbs water from the air, which creates acid inside the system. You must pull a deep vacuum before charging.

- Filter Drier: Don’t be lazy—always swap the filter drier when you open the system. It’s the cheapest insurance policy you can buy for a new compressor.

- Oil Warning: Never add mineral oil to this system. It will not mix with R134a and will eventually cause a blockage or mechanical failure.

Recommended Replacements

If you can’t find the exact QA77C17GAX5, these models are the closest matches in terms of performance and fit.

Top 5 R134a Replacements:

- Embraco: EGAS80HLR (Very common, easy to find)

- Secop: NLE7.5FT.4 (Solid European alternative)

- Jiaxipera: ND1112Y (Found in many newer fridges)

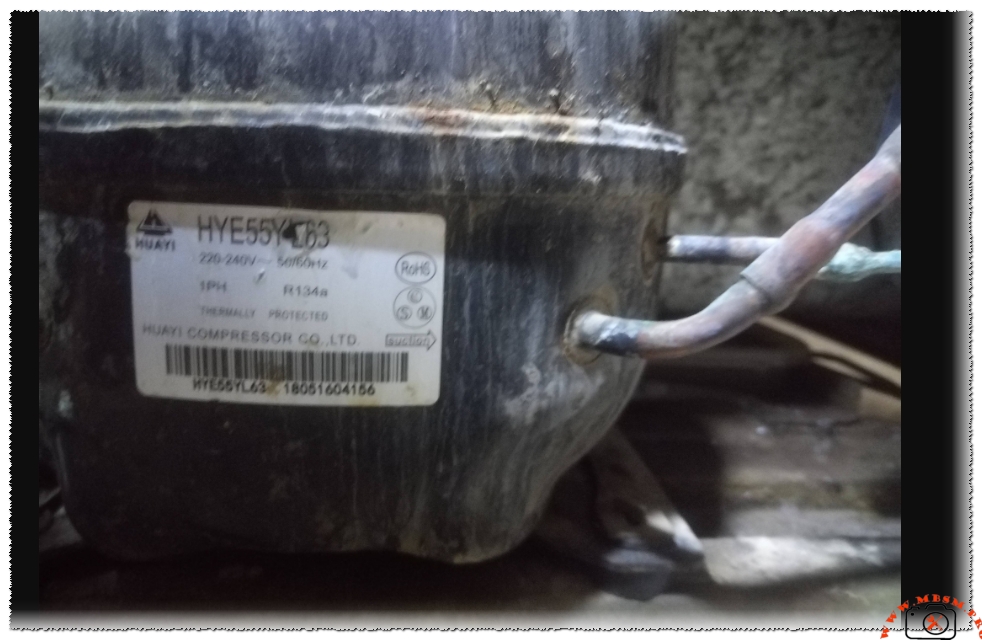

- Huayi: HYE69YG (Budget-friendly and reliable)

- Tecumseh: AE1380Y (Standard heavy-duty replacement)

5 Replacements for Other Gases (Retrofit):

Note: These require a full system flush and oil check.

- R600a (Isobutane): Panasonic QB77C16GAX5

- R290 (Propane): Embraco EMX40CLC

- R404A: Secop SC10MLX (Only for commercial setups)

- R12 (Old standard): PW7.5K14 (Hard to find now)

- R1234yf: Secop YF7.5FT (New eco-friendly standard)

The Bottom Line: The Matsushita QA77C17GAX5 is a reliable, “old-school” quality compressor. Whether you are repairing an existing fridge or designing a small cooling system, it’s a solid choice that has proven itself in the field for decades. Keep it clean, keep the system dry, and it’ll run for years.