Copeland ZR61KCE‑TF7‑522

Mbsmpro.com, Copeland, ZR61KCE‑TF7‑522, 5 hp, Scroll Compressor, Air Conditioning, R407C, 3Ph 380‑420V 50Hz, HBP, Original or Fake, Authenticity Guide

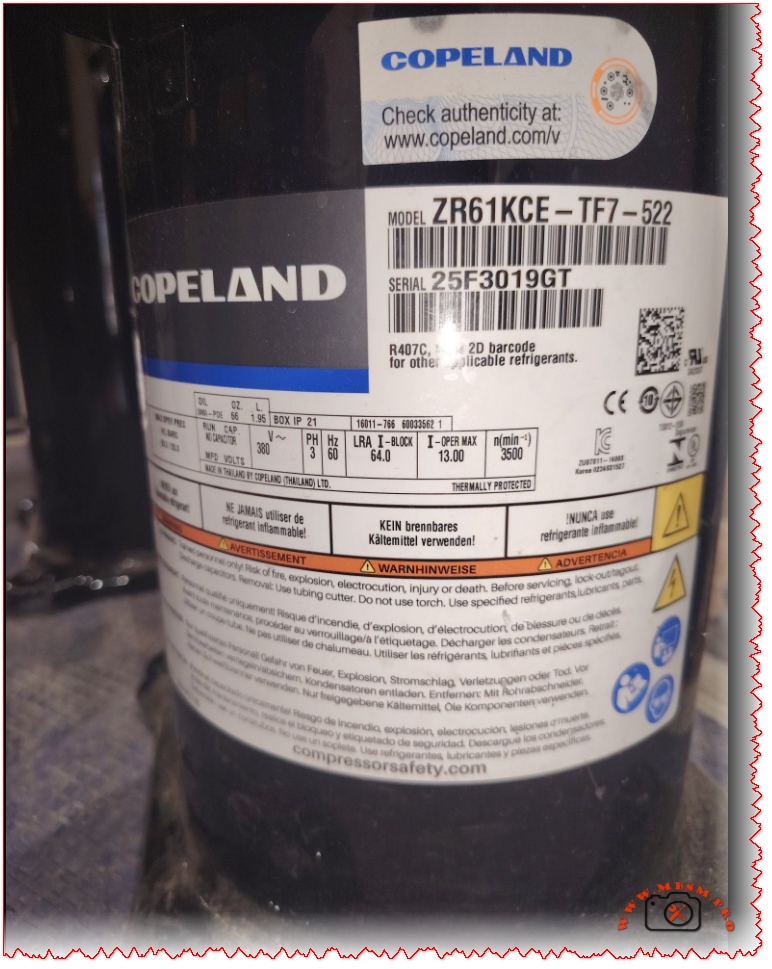

Is the Copeland ZR61KCE‑TF7‑522 compressor original?

The data plate on the Copeland ZR61KCE‑TF7‑522 in your system matches a real Copeland Scroll model in terms of model code, refrigerant, capacity range and electrical data, and it carries the official Copeland authenticity label that links to copeland.com/v, which is a standard anti‑counterfeit feature.

Visual inspection alone is never a 100 % guarantee, but the presence of the Copeland logo, correct model coding, proper serial number format and the “Check authenticity at www.copeland.com/v” label are strong indicators that this unit is genuine, provided it was purchased through an authorized distributor.

Product overview: Copeland ZR61KCE‑TF7‑522

This compressor belongs to the Copeland Scroll ZR series for air‑conditioning using mainly R407C, and equivalent variants (ZR61KCE‑TFD‑522, ZR61KCE‑TF7‑522, etc.) share the same mechanical core with different electrical codes.

Key performance data for the ZR61KCE family used with R407C:

| Parameter | Typical value ZR61KCE | Notes |

|---|---|---|

| Nominal capacity | ≈ 17.1 kW (58,500 Btu/h) | At air‑conditioning conditions with R407C |

| Power input | ≈ 5.3 kW | Three‑phase operation |

| Nominal power | 5–6 hp | High‑back‑pressure air‑conditioning duty |

| Displacement | ≈ 14.3–14.4 m³/h | Scroll, hermetic |

| Voltage range | 380‑420 V 3Ph 50 Hz (TFD/TF7 codes) | Check plate for exact rating |

| Refrigerants | R22, R134a, R407C (depending on variant) | Plate on your unit shows R407C |

| Sound pressure | ≈ 60–63 dBA @ 1 m | Low noise scroll design |

These values position the ZR61KCE as a robust medium‑capacity compressor for rooftop, split and chiller units in high‑back‑pressure applications.

How to verify that a Copeland compressor is genuine

1. Check the nameplate and logo

- The data plate must be cleanly printed, firmly fixed, and show the Copeland logo and trademark without spelling mistakes or distorted fonts.

- Model code “ZR61KCE‑TF7‑522” and serial number must follow Copeland’s standard alphanumeric format; random or repeated serials are a red flag.

2. Use the Copeland authenticity program

- Copeland runs a “Know it’s Real” program explaining that genuine compressors are distributed only through authorized wholesalers and must carry proper packaging and serial data plate.

- Many original scrolls now include an authenticity label with a QR code or a web link like copeland.com/v where installers can validate the unit by scanning or entering a code.

- If the label on your ZR61KCE‑TF7‑522 redirects to the official Copeland domain and accepts the serial, this is a strong proof of authenticity.

3. Compare with Copeland Online Product Information

- Copeland provides an Online Product Information portal and a Copeland Mobile app that list dimensions, tube sizes, electrical data and approvals by exact model number.

- Measure suction and discharge stub sizes (7/8″ and 1/2″ for ZR61KCE‑TFD‑522) and overall height (~451 mm) and compare them with the official datasheet.

- Any major mismatch in dimensions or operating limits is a warning sign.

4. Purchase channel audit

- Genuine compressors should come from authorized distributors listed on the Copeland “Where to Buy” page; suspiciously low prices or informal packaging suggest counterfeit risk.

- Copeland explicitly warns that counterfeit units are often sold with generic packaging, missing documentation, and inconsistent labels.

Technical comparison with similar scroll models

To help HVAC technicians choose the right replacement, here is a comparison between the ZR61KCE and a close relative ZR72KCE used in similar air‑conditioning applications.

Capacity and operating range

For many light commercial rooftop units or packaged chillers, the ZR61KCE is enough, but ZR72KCE offers extra margin where higher sensible loads or hotter climates are expected.

Electrical and mechanical comparison

| Feature | ZR61KCE‑TF7‑522 | ZR72KCE‑TFD‑522 |

|---|---|---|

| Voltage | 380‑420 V 3Ph 50 Hz (TFD/TF7) | 380‑420 V 3Ph 50 Hz |

| Displacement | ≈ 14.3–14.4 m³/h | ≈ 16–17 m³/h (family data) |

| Suction line | 7/8″ | 7/8″ |

| Discharge line | 1/2″ | 1/2″ |

| Sound level | ≈ 60–63 dBA | ≈ 61 dBA |

Both models share similar connection sizes, which helps in retrofits, but the ZR72KCE draws more current and requires careful checking of contactor and cable sizing.

Risks of counterfeit Copeland compressors

System damage and safety

- Copeland warns that counterfeit compressors often use poor‑quality materials, which can cause electrical failure, blown windings, or mechanical seizure, leading to catastrophic system damage.

- In severe cases, internal parts can rupture, creating a risk of refrigerant release or physical injury during operation or service.

Reduced lifespan and efficiency

- Fake units rarely achieve the design life of genuine Copeland Scroll compressors, often failing after only weeks or months in service.

- Because internal tolerances are not controlled, volumetric efficiency drops, superheat control becomes unstable, and energy consumption rises, directly increasing operating costs.

Practical tips for installers and buyers

Installation and commissioning

- Always match the compressor with the correct refrigerant (R407C for your ZR61KCE‑TF7‑522) and verify oil type (typically POE RL32‑3MAF or Mobil EAL Arctic 22 CC for this family).

- Respect Copeland limits for maximum discharge and suction pressure (≈ 29.5 bar and 20 bar) and maximum suction temperature (≈ 50 °C), and use proper crankcase heaters where required.

Documentation to keep

- Keep a clear photo of the nameplate, purchase invoice, and packaging label; these elements are useful if you need to file a warranty claim or report a counterfeit.

- For projects, link the compressor model in your technical submittals to the official Copeland catalogue pages for easy verification by consultants and clients.

Focus keyphrase (Yoast SEO)

Copeland ZR61KCE‑TF7‑522 original scroll compressor authenticity guide for R407C air conditioning systems

SEO title (Yoast SEO)

Copeland ZR61KCE‑TF7‑522 Original Scroll Compressor – Authenticity Check, Specs & Comparisons | Mbsmpro.com

Meta description (Yoast SEO)

Is your Copeland ZR61KCE‑TF7‑522 compressor original? Detailed authenticity checklist, official specs, risks of counterfeit scrolls, and comparison with ZR72KCE to help HVAC technicians choose safely.

Slug (Yoast SEO)

copeland-zr61kce-tf7-522-original-compressor-authenticity-guide

Tags

Copeland ZR61KCE, Copeland scroll compressor, R407C compressor, original Copeland, fake compressor risks, compressor authenticity, HVACR Tunisia, air conditioning compressor, ZR72KCE comparison, Mbsmgroup, Mbsm.pro, mbsmpro.com, mbsm

Excerpt (first 55 words)

The data plate on the Copeland ZR61KCE‑TF7‑522 compressor matches the official Copeland Scroll specifications for R407C air‑conditioning duty and includes the Copeland authenticity label linking to copeland.com/v, a key anti‑counterfeit feature. When purchased through an authorized distributor, these details strongly indicate that the unit installed in your system is genuine.