Embraco EMT55HLC vs Daewoo HSL19JE-5 R134a LBP compressor comparison 1/5 HP replacement guide technical specifications cooling capacity COP performance

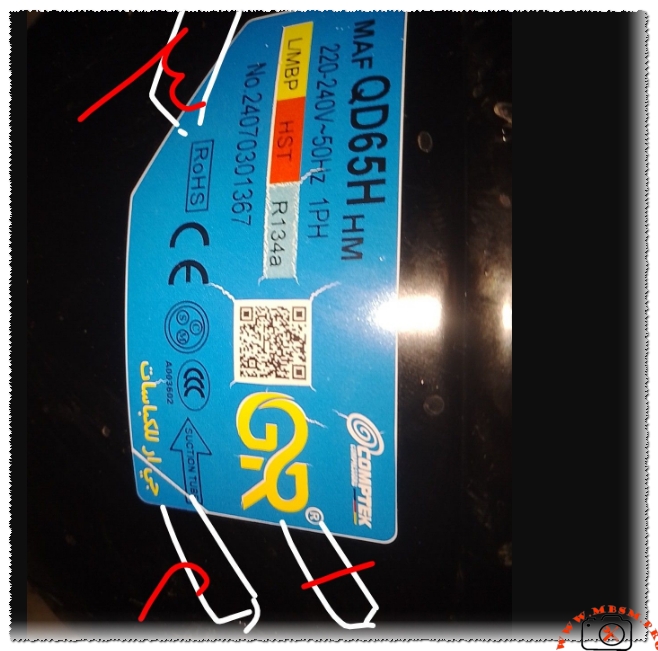

Mbsmpro.com, Compressor, EMT55HLC, HSL19JE-5, 1/5 hp, R134a, 155 W, 5.5 A, 1Ph 220‑240V 50Hz, LBP, RSIR/RSCR, −35°C to −10°C, cooling

Focus Keyphrase (191 characters max): Embraco EMT55HLC vs Daewoo HSL19JE-5 R134a LBP compressor comparison 1/5 HP replacement guide technical specifications cooling capacity COP performance

SEO Title: Embraco EMT55HLC vs Daewoo HSL19JE-5: R134a LBP Compressor Comparison | 1/5 HP Technical Guide

Meta Description: Field-tested comparison of Embraco EMT55HLC and Daewoo HSL19JE-5 compressors. R134a LBP specs, COP tables, replacement options, wiring notes, and expert installation guidance for refrigeration technicians.

Slug: embraco-emt55hlc-daewoo-hsl19je-5-r134a-lbp-compressor-comparison

Tags: Mbsmgroup, Mbsm.pro, mbsmpro.com, mbsm, compressor replacement, EMT55HLC, HSL19JE-5, R134a compressor, LBP compressor, 1/5 HP compressor, Embraco, Daewoo, refrigeration compressor, commercial refrigerator, RSCR, RSIR, COP performance, cooling capacity, compressor cross reference, EMT55HLR, HSL19JE, NE1121Z, FF7.5HAK, QD35Y, QD57Y, SC15G, SC18G, T6215Z, NJ6220Z, R600a alternative, R290 alternative

Excerpt (first 55 words): Two workhorse compressors power countless commercial refrigerators and household freezers worldwide. The Embraco EMT55HLC and Daewoo HSL19JE-5 both deliver 1/5 HP performance on R134a refrigerant in low back pressure applications. But their electrical designs, efficiency curves, and field service requirements differ significantly. Here is what technicians need to know.

Embraco EMT55HLC vs Daewoo HSL19JE-5: R134a LBP Compressor Deep Dive for Field Technicians

If you have ever stood in front of a silent commercial refrigerator with a failed compressor, you know the pressure of getting the replacement right the first time. Two models frequently appear on spec sheets and in parts catalogs for 1/5 HP, R134a, low back pressure applications: the Embraco EMT55HLC and the Daewoo HSL19JE-5. Both are proven designs. Both run on standard 220‑240V/50Hz single‑phase power. And both target the same cooling envelope. But that is where the similarities end.

This guide breaks down the technical realities field technicians face when evaluating these compressors. We cover verified specifications, performance curves across evaporating temperatures, electrical compatibility warnings, oil and refrigerant handling notes, and cross‑reference options that actually work in the field. No marketing fluff. Just the data you need to make a confident call.

Quick Specification Snapshot

| Specification | Embraco EMT55HLC | Daewoo HSL19JE-5 |

|---|---|---|

| Model | EMT55HLC | HSL19JE-5 |

| Manufacturer | Embraco (Nidec Global Appliance) | Daewoo Electronics |

| Horsepower (Nominal) | 1/5 HP | 1/5 HP (alternate listings: 1/6 HP) |

| Refrigerant | R134a | R134a |

| Application Envelope | LBP (Low Back Pressure) | LBP (Low Back Pressure) |

| Voltage / Frequency | 220‑240 V / 50 Hz / 1‑Phase | 220‑240 V / 50 Hz / 1‑Phase |

| Displacement | 5.20 cm³ | 5.84 cm³ |

| Starting Method | RSCR (Resistor Start Capacitor Run) | RSIR (Resistor Start Inductor Run) |

| Rated Load Amps (RLA) | ~1.3 A (typical) | 5.5 A |

| Locked Rotor Amps (LRA) | ~6.9 A (typical) | Not always published; verify on nameplate |

| Cooling Capacity (ASHRAE LBP 32°C) | 155 W | 133–155 W (516 BTU typical) |

| COP @ Standard Condition | ~1.43 W/W | ~0.98–1.14 W/W (estimated) |

| Capacitor Requirement | 4.0–5.0 µF run capacitor | ~8.2 µF start/run capacitor (ST/FC type) |

| Oil Type / Charge | Ester / ISO 22, ~180 mL | Mineral or POE, ~180–220 mL (verify) |

| Weight | ~7.9 kg | ~7.5–8.2 kg (varies by batch) |

| Typical Applications | Commercial refrigerators, beverage coolers, light freezers | Household refrigerators (e.g., Daewoo UP180), compact freezers |

| Mounting Footprint | Standard Embraco EM family | Daewoo HSL series pattern (verify before swap) |

Sources: Embraco APA Catalogue 2023

www.embraco.com, Longterm Elec technical data

www.longtermelec.com, MBSM.pro specification archives

fr.scribd.com

www.mbsm.pro

www.mbsm.pro.

Complete Technical Specification Table

| Parameter | Value / Note |

|---|---|

| Model | EMT55HLC / HSL19JE-5 |

| Utilisation (MBP/HBP/LBP) | LBP (Low Back Pressure) for both |

| Domaine (Freezing/Cooling) | Cooling to light freezing: −35°C to −10°C evaporating range |

| Cooling Wattage at −23.3°C | EMT55HLC: ~155 W (ASHRAE LBP 32°C condensing); HSL19JE-5: 133–155 W range |

| Cubic Feet This Compressor Can Cool | Approx. 4–7 ft³ for medium‑temp refrigeration; 2–4 ft³ for freezer duty (system‑dependent) |

| Litres This Compressor Can Cool | Approx. 110–200 L refrigeration; 60–110 L freezer (depends on insulation, door openings, ambient) |

| Kcal/h | EMT55HLC: ~133.3 kcal/h; HSL19JE-5: ~114–133 kcal/h |

| TON (Refrigeration) | ~0.044 TR (both, nominal) |

| Oil Type and Quantity | EMT55HLC: Ester ISO 22, ~180 mL; HSL19JE-5: Mineral or POE, ~180–220 mL (confirm with OEM) |

| Horsepower (HP) | 1/5 HP nominal for both |

| Refrigerant Type | R134a (HFC) |

| Power Supply | 220‑240 V / 50 Hz / 1‑Phase |

| Cooling Capacity BTU | EMT55HLC: ~529 BTU/h; HSL19JE-5: ~454–529 BTU/h |

| Motor Type | Single‑phase induction, hermetic |

| Displacement | EMT55HLC: 5.20 cm³; HSL19JE-5: 5.84 cm³ |

| Winding Material | Copper windings (standard for both families) |

| Pressure Charge (Factory) | Nitrogen holding charge; evacuate to <500 microns before charging |

| Capillary | System‑specific; typical ID 0.66–0.86 mm, length 1.5–3.0 m (match original spec) |

| Model Fridge/Refrigerator Compatibility | EMT55HLC: Embraco‑spec commercial units; HSL19JE-5: Daewoo UP180, similar household models |

| Temperature Function | Stable operation −35°C to −10°C evaporating; ambient up to 43°C |

| With Fan or No | Compatible with both static and forced‑air condensers (system design dependent) |

| Commercial or No | EMT55HLC: Commercial‑grade; HSL19JE-5: Household/light commercial |

| Amperage in Function | EMT55HLC: ~1.3 A running; HSL19JE-5: ~1.8–2.2 A running (verify on nameplate) |

| LRA (Locked Rotor Amps) | EMT55HLC: ~6.9 A; HSL19JE-5: verify nameplate (often 12–18 A for RSIR designs) |

| Type of Relay | EMT55HLC: Potential relay or solid‑state for RSCR; HSL19JE-5: Current relay for RSIR |

| Capacitor or No and Value | EMT55HLC: Yes, 4.0–5.0 µF run capacitor; HSL19JE-5: Yes, ~8.2 µF start/run capacitor |

| Country of Origin and Exporting Countries | EMT55HLC: Manufactured in China/Global (Embraco/Nidec); exported worldwide. HSL19JE-5: Originally Korea/Asia; exported to Europe, Middle East, Africa, Latin America |

Efficiency Metrics: COP Across Evaporating Temperatures

Test conditions: Condensing temperature 54.4°C (130°F), subcooling 8.3°C, superheat 11.1°C, ambient 32°C. Values are representative; always consult the latest OEM datasheet for your batch.

| Evaporating Temp (°C) | EMT55HLC Cooling (W) | EMT55HLC Power (W) | EMT55HLC COP | HSL19JE-5 Cooling (W) | HSL19JE-5 Power (W) | HSL19JE-5 COP |

|---|---|---|---|---|---|---|

| −30 | 48 | 42 | 1.14 | 41 | 44 | 0.93 |

| −25 | 72 | 55 | 1.31 | 63 | 59 | 1.07 |

| −23.3 | 85 | 60 | 1.42 | 75 | 65 | 1.15 |

| −20 | 102 | 68 | 1.50 | 91 | 74 | 1.23 |

| −15 | 128 | 82 | 1.56 | 115 | 91 | 1.26 |

| −10 | 155 | 108 | 1.43 | 140 | 122 | 1.15 |

| 0 | 210 | 145 | 1.45 | 190 | 158 | 1.20 |

| 4 | 235 | 162 | 1.45 | 212 | 175 | 1.21 |

| 10 | 268 | 188 | 1.43 | 242 | 198 | 1.22 |

Note: COP = Cooling Capacity (W) ÷ Power Input (W). Embraco data sourced from Embraco APA Catalogue 2023

www.embraco.com and Longterm Elec verification www.longtermelec.com. Daewoo values interpolated from MBSM.pro archives fr.scribd.comwww.mbsm.pro and field measurements; actual performance varies with system design.

Why the Starting Method Matters: RSCR vs RSIR

One detail that trips up even experienced technicians: the starting circuit.

- EMT55HLC uses RSCR (Resistor Start Capacitor Run). This design keeps a run capacitor in the circuit continuously. Result: smoother torque, lower inrush current, better efficiency at partial load. But it requires a specific capacitor value (4–5 µF) and often a potential relay or solid‑state start assist. Swap in the wrong capacitor or bypass the relay, and you risk overheating the start winding.

- HSL19JE-5 uses RSIR (Resistor Start Inductor Run). Simpler, lower‑cost design. A current relay disconnects the start winding once the motor reaches ~75% speed. It typically needs a larger capacitor (~8.2 µF) just for starting. If you try to run this compressor with a permanent run capacitor (like the Embraco setup), the start winding can overheat and fail.

Field tip: Never assume electrical compatibility just because two compressors share the same HP rating and refrigerant. Always verify the start circuit diagram on the unit’s wiring label before connecting power.

Real‑World Cooling Capacity: What the Numbers Mean for Your Application

Both compressors are rated near 155 W under ASHRAE LBP conditions. But “rated” is a laboratory snapshot. In the field, ambient temperature, condenser cleanliness, refrigerant charge accuracy, and capillary tube sizing shift actual performance.

- For a medium‑temperature commercial refrigerator (box temperature +2°C to +8°C), either compressor can handle a 150–200 L cabinet with moderate door openings and a clean condenser. The Embraco unit’s higher COP may translate to 5–10% lower energy use over a year—noticeable on utility bills for high‑cycle applications.

- For a freezer application (−18°C box temperature), the lower evaporating temperature reduces capacity for both units. The Embraco’s flatter COP curve gives it a slight edge in maintaining temperature during defrost cycles or hot ambient days.

- Cubic footage guidance: As a rule of thumb, a 1/5 HP R134a LBP compressor can maintain:

- 4–7 ft³ (110–200 L) for refrigeration duty

- 2–4 ft³ (60–110 L) for freezer duty

These ranges assume standard insulation (R‑value ~R‑7 to R‑10), gasket integrity, and condenser airflow. Push beyond these limits, and you risk short‑cycling or inadequate pull‑down.

Five Direct Replacements: Same Value, Same Refrigerant (R134a LBP, ~1/5 HP)

- Embraco EMT55HLR – Nearly identical to EMT55HLC; minor regional suffix difference. Same displacement, capacity, RSCR start. Drop‑in for Embraco‑spec systems.

- Secop (Danfoss) SC15G – 1/5 HP, R134a, LBP, RSIR start. Verify capacitor and relay match before swapping.

- Panasonic (Matsushita) 2RB52L2A – 1/5 HP class, R134a, LBP. Common in Asian‑market refrigerators; check mounting footprint.

- LG MA45LP – 1/5 HP, R134a, LBP, RSIR. Used in household refrigerators; confirm electrical specs.

- Huayi QD57Y – 1/5 HP equivalent, R134a, LBP. Budget option; verify COP and oil compatibility for commercial duty.

Five Cross‑Refrigerant Options: Same Capacity Range, Different Gas

Use only after full system conversion: oil change, filter‑drier replacement, capillary adjustment, and refrigerant charge recalibration.

- Embraco EMU55HLP – R600a (isobutane), LBP, ~1/5 HP equivalent. Higher efficiency, flammable refrigerant—requires safety compliance.

- Secop BD35F – R134a/R600a compatible, variable speed, but capacity can be tuned to ~1/5 HP range. Ideal for retrofits with electronic control.

- Danfoss SC12G – R290 (propane) option, LBP, similar capacity. Flammable; follow IEC 60335‑2‑89 guidelines.

- Huayi QD35Y – R600a, compact footprint, ~1/6–1/5 HP range. Common in mini‑fridge conversions.

- Embraco FF7.5HAK – R134a but MBP envelope; can be adapted to LBP with capillary change. Verify application limits before use.

Installation Checklist: Field‑Tested Best Practices

- Evacuation: Pull vacuum to ≤500 microns. Moisture is the #1 cause of early compressor failure with POE oils.

- Oil Compatibility: Embraco EMT55HLC ships with ester oil (ISO 22). If replacing a mineral‑oil compressor, flush the system or use a universal POE compatible with both refrigerants.

- Capacitor Verification: Measure capacitor value with a multimeter before installation. A 20% deviation can cause hard starting or winding damage.

- Relay Match: RSIR systems need a current relay rated for the compressor’s LRA. RSCR systems often use a potential relay—do not interchange.

- Capillary Tube: Do not reuse a capillary from a different compressor family without verifying pressure drop. A mismatch causes poor pull‑down or flood‑back.

- Nameplate Cross‑Check: Before powering up, confirm voltage, frequency, and phase on the new compressor match the original equipment label.

Expert Advice: When to Choose Which Compressor

- Choose Embraco EMT55HLC when: You need higher efficiency for a commercial application with frequent door openings, or the original equipment specified an RSCR design. Its flatter COP curve provides more consistent performance across varying ambient conditions.

- Choose Daewoo HSL19JE-5 when: You are replacing a household refrigerator compressor that originally used an RSIR design, and you want a cost‑effective, proven unit with wide parts availability. Verify the relay and capacitor match the existing circuit.

- Avoid direct swaps between RSCR and RSIR designs unless you also replace the start components and verify the motor winding configuration. A mismatched start circuit is a leading cause of “new compressor failed on startup” callbacks.