LG washing machine error codes troubleshooting

Focus Keyphrase: LG washing machine error codes troubleshooting guide for professional technicians and home maintenance Mbsmpro

SEO Title: Mbsmpro.com, LG Washing Machine, Error Codes, OE, IE, UE, LE, CL, Troubleshooting, Repair Solutions, Appliance Maintenance Guide

Meta Description: Master LG washing machine repairs with this expert guide. Learn to decode OE, IE, UE, and LE error codes with professional field-tested solutions from Mbsmpro.

Slug: lg-washing-machine-error-codes-troubleshooting-guide-mbsmpro

Tags: LG Washing Machine, Error Codes, Troubleshooting, OE Error, IE Error, UE Error, CL Child Lock, Motor Lock LE, Appliance Repair, Maintenance Tips, Mbsmgroup, Mbsm.pro, mbsmpro.com, mbsm

Excerpt: Decoding LG washing machine error codes is essential for any technician or homeowner looking to maintain peak performance. From the common OE drainage error to the complex LE motor lock fault, understanding these digital signals saves time and prevents further damage. This comprehensive Mbsmpro guide provides field-tested solutions to keep your laundry appliances running efficiently.

Mbsmpro.com, LG Washing Machine, Error Codes, OE, IE, UE, LE, Troubleshooting, Maintenance Guide

In the modern world of smart appliances, LG washing machines stand out for their efficiency and advanced self-diagnostic systems. However, when the digital display flashes an alphanumeric code instead of the remaining cycle time, it can be frustrating for the end-user. As an engineering-focused field expert, I have spent years analyzing these systems to provide a definitive guide for troubleshooting and repair.

Understanding these codes is not just about clearing a notification; it is about diagnosing the mechanical or electronic root cause to ensure the longevity of the appliance. Below is a comprehensive breakdown of the most frequent faults encountered in the field.

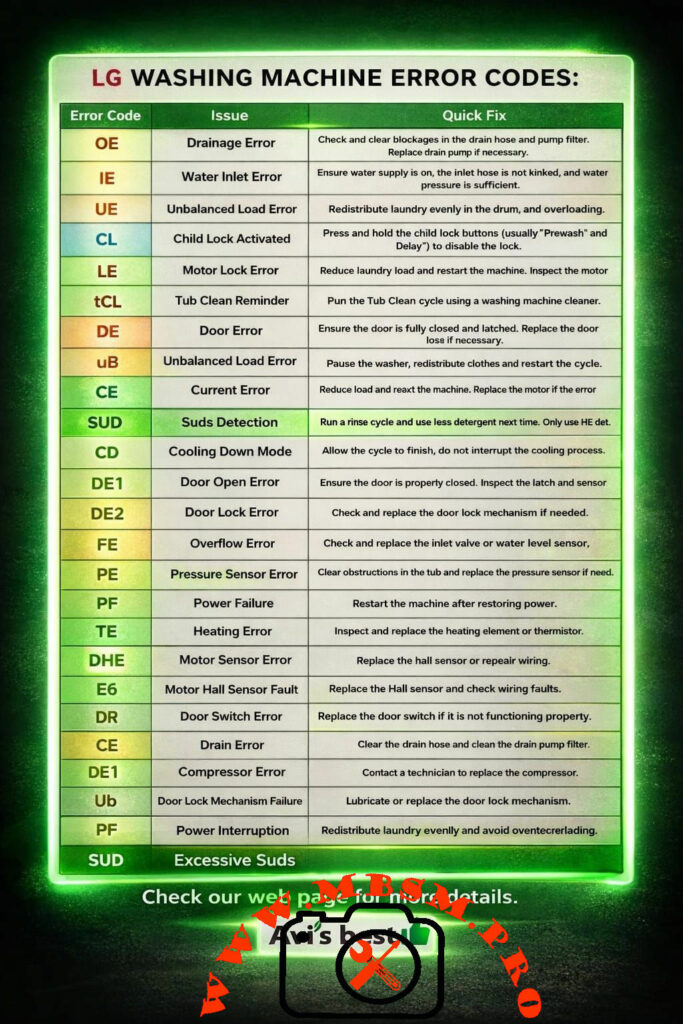

Comprehensive LG Error Code Reference Table

The following table serves as a primary diagnostic tool for identifying common issues and their immediate resolutions.

| Error Code | Issue Description | Professional Diagnostic & Quick Fix |

| OE | Drainage Error | Inspect the drain hose for kinks. Clean the pump filter. Test the drain pump motor for continuity. |

| IE | Water Inlet Error | Verify water supply valves are open. Check inlet filters for sediment. Ensure house water pressure is adequate. |

| UE / uB | Unbalanced Load | Redistribute laundry evenly. Ensure the machine is perfectly level on the floor. |

| CL | Child Lock Activated | Not a fault. Press and hold the “Child Lock” button combination (often Prewash/Delay) for 3 seconds. |

| LE | Motor Lock Error | Possible heavy load. Reduce weight. Inspect the wiring harness between the PCB and the stator. |

| tCL | Tub Clean Reminder | Maintenance prompt. Execute the Tub Clean cycle using a high-quality citric-acid-based cleaner. |

| DE / DE1 / DE2 | Door Error / Lock Fault | Ensure the door is fully latched. Inspect the door switch and solenoid for electrical failure. |

| CE | Current / Drain Error | Can indicate a short circuit in the motor or a drainage obstruction. Inspect the main control board for scorch marks. |

| SUD | Excessive Suds Detection | High-efficiency (HE) detergent usage is mandatory. Run a rinse cycle to clear the drum. |

| FE | Overflow Error | Typically caused by a faulty water inlet valve that fails to close or a defective pressure sensor. |

| PE | Pressure Sensor Error | Check the air tube connecting the drum to the pressure switch. Verify the sensor’s frequency output. |

| PF | Power Failure | Indicates an interruption in electrical supply. Restart the cycle once power is stabilized. |

| TE | Heating Error | Inspect the heating element and the thermistor (NTC). Measure resistance values (typical 10k-15k ohms at room temp). |

| DHE | Motor Sensor Error | Focus on the Hall Effect sensor located on the back of the stator. |

| E6 | Motor Hall Sensor Fault | Often requires replacement of the Hall sensor or repairing the wiring harness. |

Engineering Analysis: Sensors and Electronic Components

When a washing machine displays an error, it is reacting to data provided by specific electronic sensors. For the technician, understanding the electrical characteristics of these parts is vital.

Electrical Specification Comparison Table

| Component | Expected Value (Approx.) | Fault Symptom |

| Inlet Valve Solenoid | 1.1k – 1.5k Ohms | IE Error, No water entry |

| Drain Pump Motor | 150 – 200 Ohms | OE Error, Standing water |

| Thermistor (NTC) | 10k – 15k Ohms (at 25°C) | TE Error, Water not heating |

| Stator Windings | 8 – 12 Ohms (between pins) | LE Error, Motor stuttering |

| Door Lock Solenoid | 50 – 150 Ohms | DE2 Error, Door won’t lock |

Electronic Logic Schema (Simplified)

[Main PCB] <–> [Pressure Switch (PE)] <–> [Water Level Frequency]

[Main PCB] <–> [Hall Sensor (LE/E6)] <–> [Motor RPM Tracking]

[Main PCB] <–> [Thermistor (TE)] <–> [Temperature Feedback]

Comparative Study: LG vs. Industry Standards

In comparison to brands like Samsung or Whirlpool, LG utilizes a Direct Drive motor system in many models. This eliminates the belt, which reduces common mechanical “No Spin” errors found in older machines. However, it places more importance on the Hall Sensor (RPM sensor). While a Whirlpool might show a “Suds” error, LG’s SUD detection is often more sensitive to the specific viscosity of the water, requiring stricter adherence to HE detergent standards.

Professional Advice and Notices

- Notice on Maintenance: Always perform a tCL (Tub Clean) cycle at least once a month. This prevents the buildup of biofilm which can interfere with the PE (Pressure Sensor) accuracy.

- Benefit of Proper Leveling: A perfectly level machine significantly reduces the occurrence of UE (Unbalanced Load) errors and prevents premature wear on the shock absorbers.

- Engineering Tip: If you encounter an LE error on a new machine, always check the wiring harness at the bottom of the tub. During high-vibration shipping, these connectors can sometimes wiggle loose.

Technical Troubleshooting Summary

- Safety First: Always disconnect the power supply before inspecting internal components.

- Visual Inspection: 60% of OE and IE errors are caused by external factors like clogged house filters or pinched hoses.

- Sensor Cleaning: Before replacing a PE sensor, blow air through the pressure tube to ensure there is no “water log” or debris blocking the signal.

Mbsmgroup remains committed to providing the highest quality technical insights for the appliance repair industry. Whether you are a master engineer or a dedicated DIYer, following these diagnostic steps will ensure your LG Washing Machine operates at peak performance for years to come.