Donper LG83WZ1 Refrigeration Compressor Technical Specifications and R134a Replacement Guide for Unionaire refrigerator

Focus Keyphrase: Donper LG83WZ1 Refrigeration Compressor Technical Specifications and R134a Replacement Guide

SEO Title: Mbsmpro.com, Compressor, LG83WZ1, 1/4 HP+, Donper, Cooling, R134a, 230 W, 1.4 A, 1Ph 220-240V 50Hz, LBP, Freezing

Meta Description: Explore the comprehensive technical specs for the Donper LG83WZ1 compressor. Includes cooling capacity, replacement cross-references, and performance data for R134a systems.

Slug: donper-lg83wz1-compressor-specifications-r134a-replacement

Tags: Donper, LG83WZ1, R134a, 1/4 HP+, Refrigerator Compressor, Mbsmgroup, Mbsm.pro, mbsmpro.com, mbsm, Embraco FFI8.5HAK, Secop NLE8.8MF, LG MA88LAEP, Panasonic QB86C16GAX5, Tecumseh THG1374YS, LBP Compressor

Excerpt: The Donper LG83WZ1 stands as a cornerstone in modern domestic and light commercial refrigeration. Engineered for Low Back Pressure applications, this R134a-driven unit provides reliable cooling capacity for medium to large refrigerators. Its 8.3cc displacement ensures consistent thermal management, making it a preferred choice for technicians seeking a robust, thermally protected motor for demanding climates.

The Engineering Behind Reliability: A Deep Dive into the Donper LG83WZ1 Compressor

In the precision-driven world of refrigeration, the compressor is the heart of the thermal cycle. Among the workhorses found in modern residential and light commercial units, the Donper LG83WZ1 has earned a reputation for resilience and steady performance. As a Low Back Pressure (LBP) specialist, this model is specifically designed to handle the rigorous demands of freezing and deep-cooling applications where maintaining sub-zero temperatures is non-negotiable.

Technical Performance and Infrastructure

The LG83WZ1 utilizes R134a refrigerant, a long-standing industry standard known for its thermodynamic stability. With a displacement of 8.3 cm³, it sits comfortably in the 1/4 HP+ to 1/3 HP class, providing enough “muscle” for large household refrigerators or vertical display freezers. The motor is a single-phase, thermally protected unit operating on a standard 220-240V 50Hz supply, making it a universal fit for many international markets.

Comprehensive Technical Specifications

| Feature | Specification |

| Model | LG83WZ1 |

| Utilization | LBP (Low Back Pressure) |

| Domaine | Freezing / Deep Cooling |

| Cooling Wattage at -23.3°C | 230 W |

| Cubic Feet Capacity | 14 – 18 cu.ft. |

| Liters Capacity | 400 – 500 Liters |

| Kcal/h | 198 Kcal/h |

| Oil Type and Quantity | Ester Oil (POE) / 180ml |

| Horsepower (HP) | 1/4 HP+ |

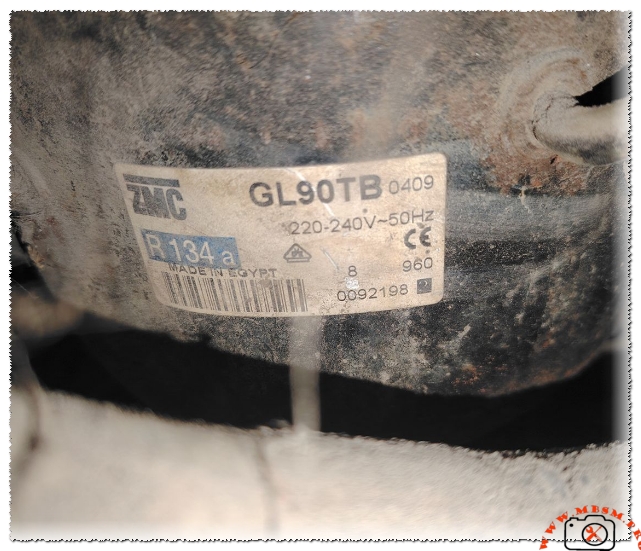

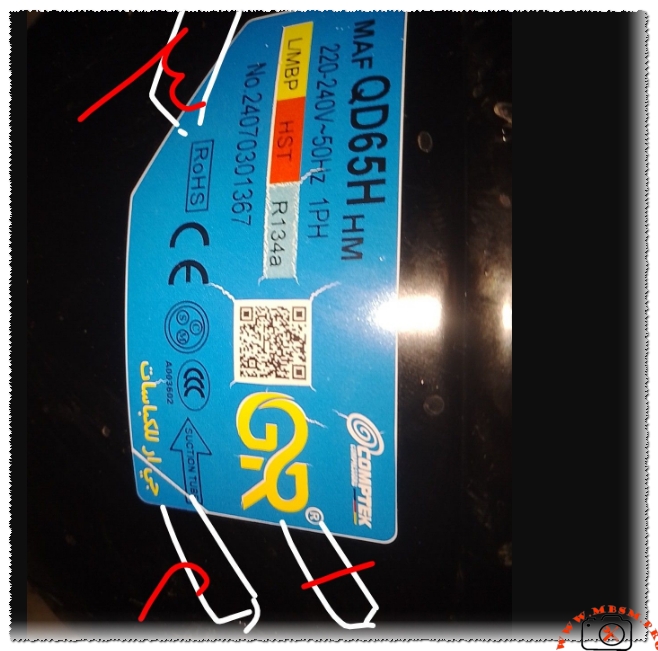

| Refrigerant Type | R134a |

| Power Supply | 220–240V / 50Hz / 1Ph |

| Cooling Capacity (BTU/h) | 785 BTU/h |

| Motor Type | RSIR / RSCR (depending on start kit) |

| Displacement | 8.3 cm³ |

| Winding Material | High-Grade Copper |

| Suction Pressure Charge | 0.5 to 1.2 Bar (system dependent) |

| Capillary Recommendation | 0.031″ or 0.036″ ID |

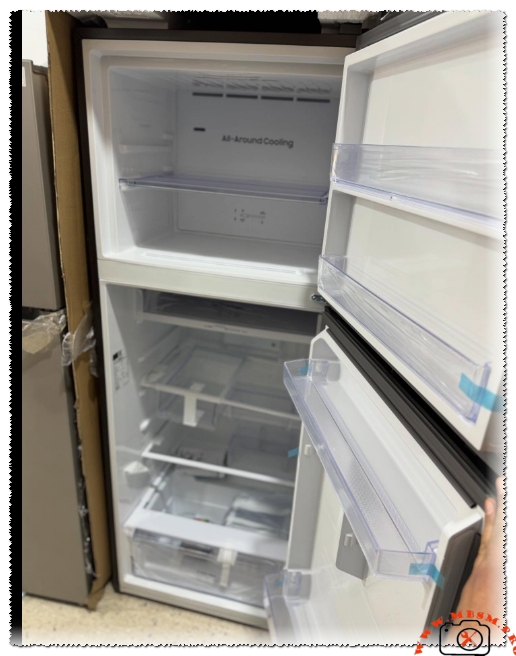

| Common Application | Double-door refrigerators, Chest Freezers |

| Temperature Function | -35°C to -15°C |

| Cooling Method | Static or Fan Assisted |

| Commercial Status | Semi-Commercial / Residential |

| Amperage (FLA) | 1.4 A |

| LRA (Locked Rotor Amps) | 11.5 A |

| Relay Type | PTC or Magnetic |

| Start Capacitor | Optional (usually 60-80 µF if used) |

| Origin | China (Global Export) |

Efficiency Metrics (COP)

Understanding the Coefficient of Performance (COP) is vital for energy-conscious engineering. The LG83WZ1 shows its strengths in the mid-range of LBP operations.

| Evaporating Temp (°C) | Cooling Capacity (Watts) | Power Consumption (Watts) | COP (W/W) |

| -30 | 165 | 148 | 1.11 |

| -25 | 215 | 165 | 1.30 |

| -23.3 (ASHRAE) | 230 | 172 | 1.34 |

| -20 | 275 | 185 | 1.48 |

| -15 | 345 | 205 | 1.68 |

| -10 | 430 | 230 | 1.87 |

Direct Replacement Cross-Reference

When a compressor fails in the field, speed and accuracy in replacement are paramount. Below are the most compatible units based on displacement and cooling capacity.

5 Replacements: Same Refrigerant (R134a)

| Brand | Model | HP Equivalent | Displacement |

| Embraco | FFI8.5HAK | 1/4 HP+ | 8.5 cm³ |

| Secop | NLE8.8MF | 1/3 HP | 8.8 cm³ |

| LG | MA88LAEP | 1/4 HP+ | 8.8 cm³ |

| Panasonic | QB86C16GAX5 | 1/4 HP+ | 8.6 cm³ |

| Tecumseh | THG1374YS | 1/4 HP | 7.4 cm³ |

5 Replacements: Alternative Refrigerant (R600a)

Note: Converting from R134a to R600a requires a complete system flush, lubricant change, and capillary adjustment.

| Brand | Model | HP Equivalent | Gas Type |

| :— | :— | :— | :— |

| Embraco | EMX70CLC | 1/4 HP | R600a |

| Secop | TLES7.5KK.3 | 1/4 HP | R600a |

| LG | MK88LAEM | 1/4 HP+ | R600a |

| Donper | B80H | 1/4 HP | R600a |

| Jiaxipera | NT1114Y | 1/4 HP | R600a |

Comparative Analysis: R134a vs. R600a Performance

While the LG83WZ1 uses R134a, the industry is shifting toward R600a (Isobutane). Comparing these two helps technicians understand why the LG83WZ1 remains a staple for repairs:

- Pressure: R134a operates at higher discharge pressures than R600a, allowing for faster heat transfer in smaller condenser coils.

- Charge Weight: R134a systems require a higher gram-weight charge than R600a, making the LG83WZ1 less sensitive to minor leaks.

- Oil Compatibility: The LG83WZ1 uses POE (Polyolester) oil, which is highly hygroscopic. Unlike the mineral oils used in R600a units, the LG83WZ1 requires strict moisture control during service.

Electrical Schematic and Wiring Guide

For field workers, identifying the terminal configuration is the first step to a successful installation. The LG83WZ1 typically follows the standard triangular pin layout.

Engineering Tip: Always verify the resistance between the Start (S), Main (M), and Common (C) terminals. On the LG83WZ1, the Main winding typically shows lower resistance than the Start winding.

Field Advice and Professional Notices

- Vacuum Integrity: Because this compressor uses Ester oil, you must pull a vacuum to at least 500 microns. Moisture reacting with POE oil creates acid that can etch the motor windings, leading to premature burnout.

- Filter Drier Replacement: Never install a new LG83WZ1 without replacing the filter drier. A clogged drier is the number one cause of high head pressure and motor failure.

- Condenser Maintenance: In commercial settings, ensure the condenser fins are cleaned every six months. The LG83WZ1 is robust, but excessive heat from a dirty condenser will trip the thermal protector and reduce the unit’s lifespan.

Benefits for the End User

- Low Noise Floor: Designed with internal dampening springs to reduce vibration.

- High Torque Start: Capable of starting under moderate pressure fluctuations, making it reliable in regions with unstable power grids.

- Longevity: When paired with a clean system, these compressors are known to exceed 10 years of service life.