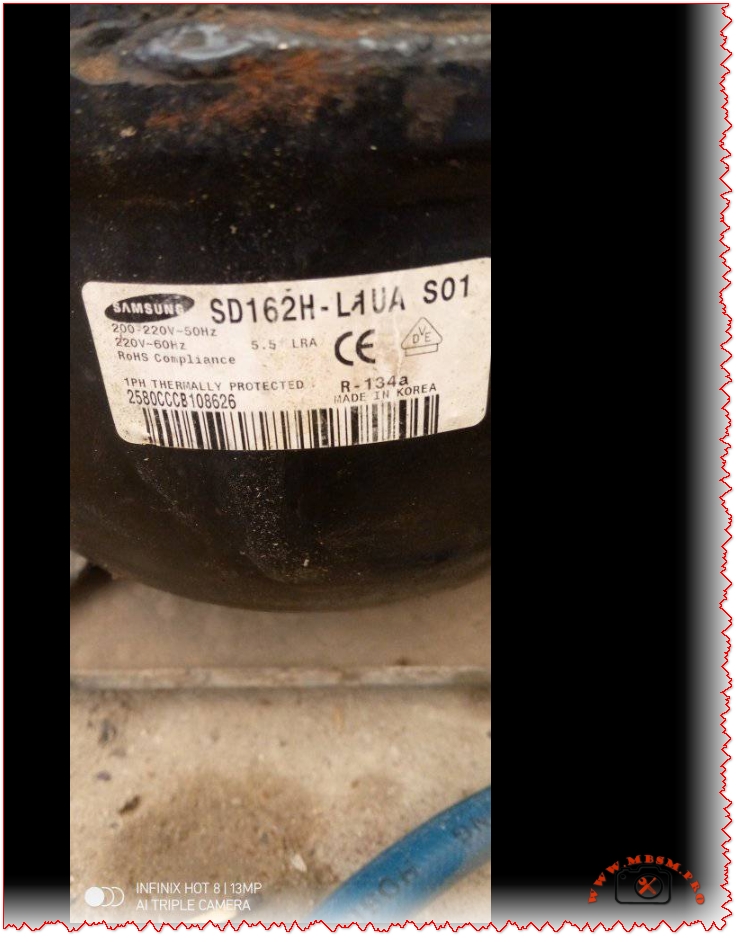

Samsung SD162H‑L4UA S01, hermetic , compressor

Samsung SD162H‑L4UA S01, 1/5 HP, R134a, 200‑220V 50Hz / 220V 60Hz, LBP Refrigerator Compressor – Specifications, Performance Tables, Use & Comparison

Model overview

The Samsung SD162H‑L4UA S01 is a hermetic reciprocating compressor designed for small household refrigerators using R134a refrigerant, with dual‑voltage operation at 200‑220V 50Hz and 220V 60Hz.

It belongs to the SD162 family widely used in under‑counter and reach‑in cabinets where high efficiency, reliable starting, and low noise are required.

Electrical and identification data

This section summarizes the key electrical characteristics typically associated with the SD162H series working with R134a in low back pressure applications.

These values make the Samsung SD162H‑L4UA suitable for compact refrigerators in the 150–250 liter class where moderate starting current and good efficiency are important.

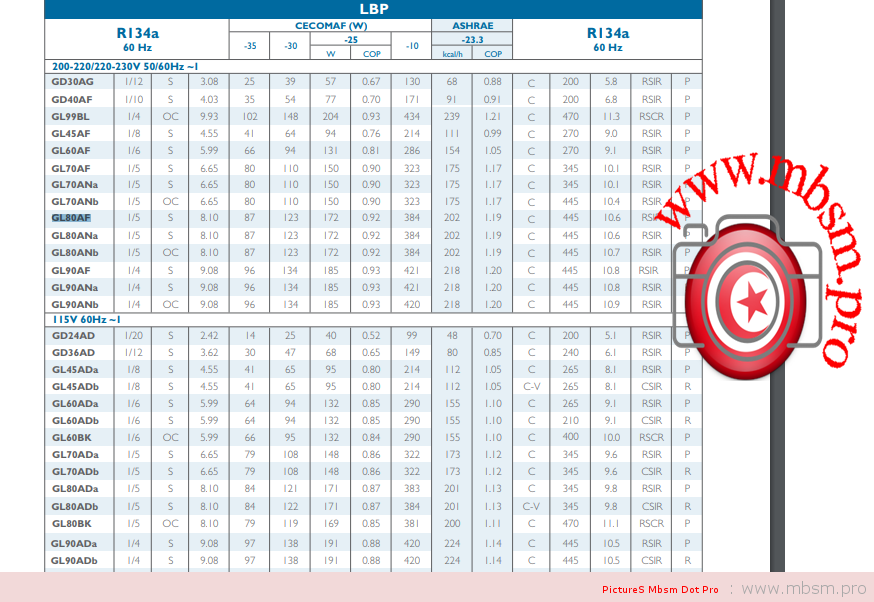

Cooling performance and application range

Samsung does not publish an open public sheet for every sub‑suffix, but performance can be estimated from SD162Q‑L1UA and similar 1/5 HP R134a LBP models.

In practical use this means the compressor can work both in standard refrigerator mode around −10 °C evaporating and in small freezer compartments near −25 °C with reduced capacity but stable operation.

Comparison with similar R134a compressors

To help with replacement and design decisions, the next table compares Samsung SD162H‑L4UA with two other 1/5–1/4 HP R134a hermetic compressors often referenced in technical catalogs.

R134a domestic compressors comparison

Compared with SD162Q‑L1UA, the SD162H‑L4UA keeps similar capacity but offers a label‑specified 5.5 A LRA, which can be interesting when designing systems with modest starting current constraints.

Against ACC GL80AN, the Samsung unit generally has slightly lower displacement, making it better suited to compact cabinets where low noise and reduced energy use are more critical than maximum capacity.

Practical exploitation, reliability and installation tips

In workshop practice the Samsung SD162H‑L4UA S01 is appreciated for:

- Strong load capacity during pull‑down of warm cabinets, inherited from the SD162 series design.

- Reliable starting performance thanks to the RSCR/RSIR motor concept combined with an internal thermal protector.

- Low noise and vibration, making it acceptable for domestic kitchens and small commercial premises.

When using this compressor as a replacement:

- Match refrigerant (R134a), voltage, and application range (LBP) to the original unit to avoid overheating and low capacity.

- Keep suction line sizing close to Samsung recommendations in general catalogs to preserve return gas cooling and oil return.

- Use clean‑brazing practice and always replace the filter‑drier after opening the circuit to protect the compressor against moisture and acids.