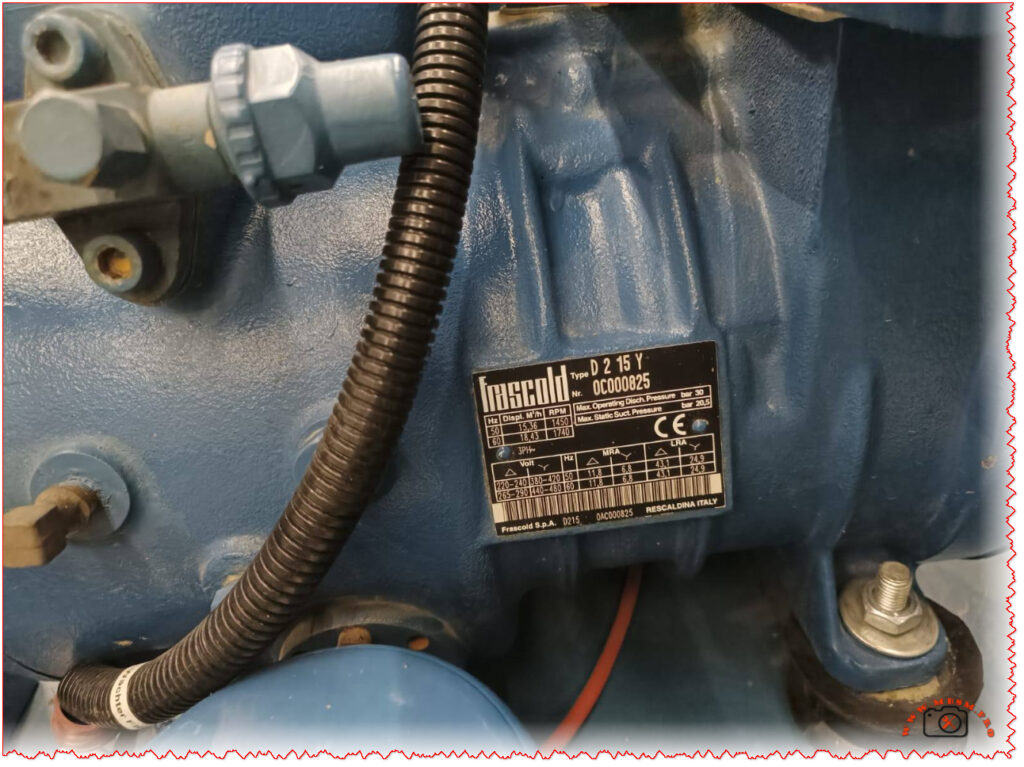

Frascold D2‑15Y / D2‑15.1Y

Frascold D2 15Y: semi‑hermetic compressor for reliable commercial refrigeration

General overview

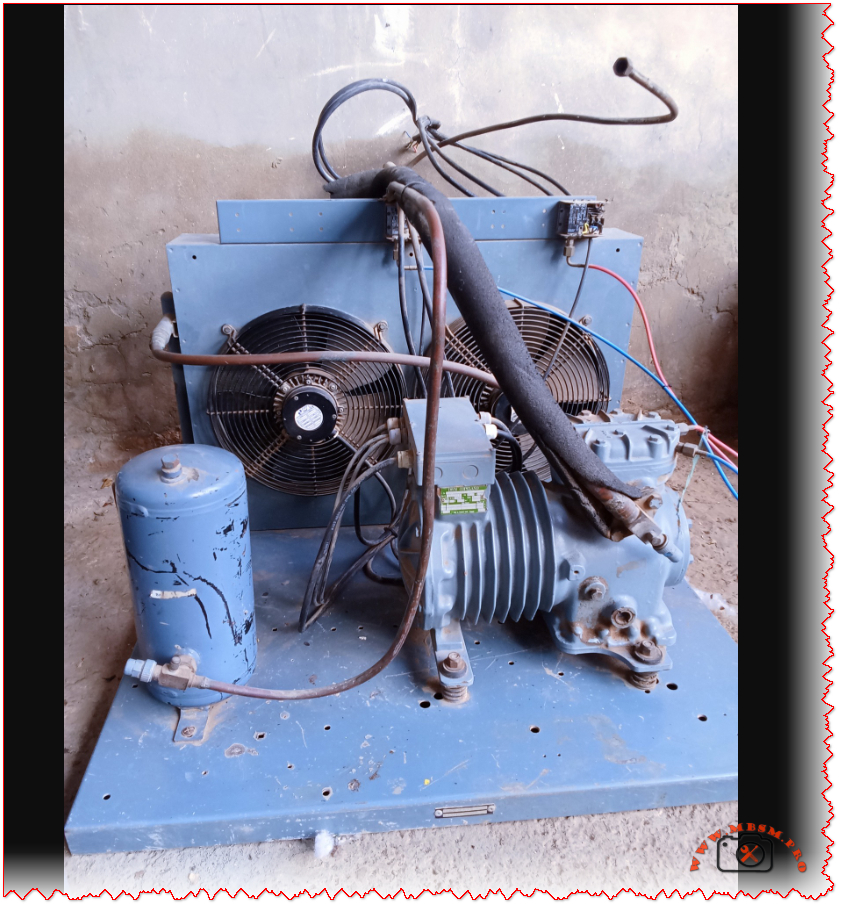

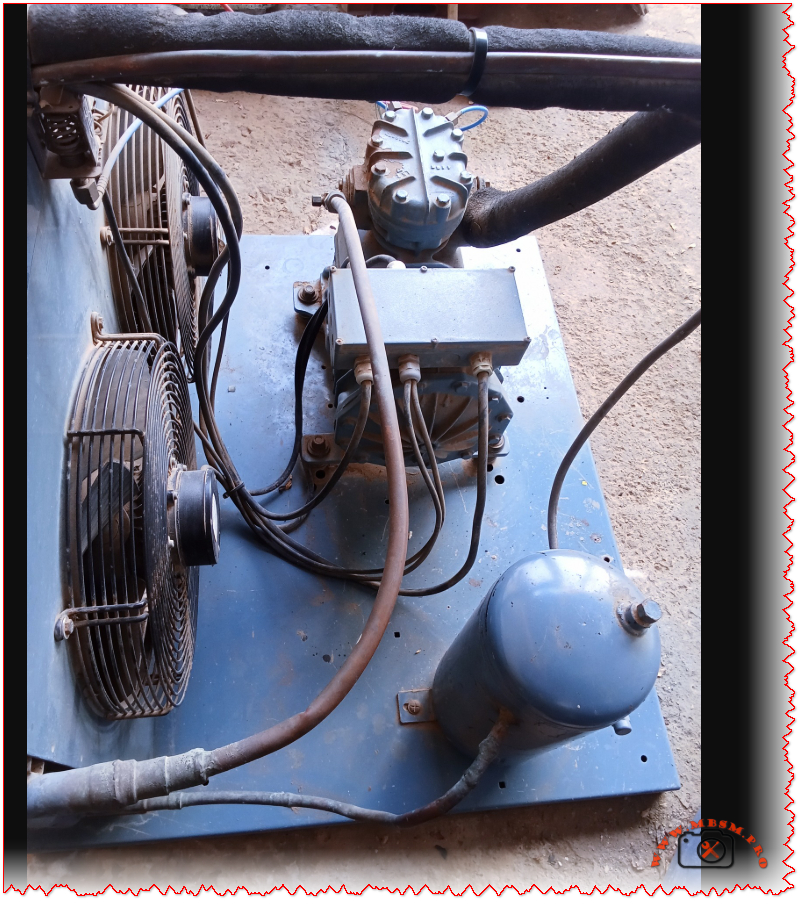

The Frascold D2 15Y is a two‑cylinder, semi‑hermetic reciprocating compressor designed for low‑ and medium‑temperature commercial and industrial refrigeration duties. With a displacement of about 15.4 m³/h at 50 Hz and a nominal motor power of 1.5 kW (2 HP), it fits perfectly in small to medium cold rooms, display cabinets and process coolers.

This model belongs to Frascold’s D series, known for compact cast‑iron bodies, quiet operation and high energy efficiency under EN12900 test conditions. The D2 15Y can be supplied as a bare compressor or integrated into silent condensing units, giving installers flexibility in plant design.

Key technical features

Frascold’s data show that the D2 15Y delivers around 6–7 kW of cooling capacity with R404A in typical low‑temperature duty, depending on evaporating and condensing conditions. The compressor is charged with POE oil (approx. 1.1 L) and uses robust suction and discharge service valves to facilitate commissioning and service.

Electrical supply options usually cover 220–240 V/3/50 Hz and 380–420 V/3/50 Hz (with corresponding 60 Hz variants), allowing use across most European three‑phase networks. The unit is compatible with multiple refrigerants, including R22, R134a, R404A, R507A, R407A/F, and new lower‑GWP blends such as R448A and R449A.

Table – Main data for Frascold D2 15Y

Benefits for HVACR professionals

Semi‑hermetic design means the D2 15Y can be opened for internal inspection and overhaul, extending service life compared with fully hermetic units in demanding duty cycles. The compressor is also suitable for operation with variable‑frequency drives, enabling smooth capacity modulation from part‑load to peak demand while improving seasonal efficiency.

For contractors and wholesalers, the D2 15Y’s widespread availability and clear documentation (including a dedicated PDF datasheet and full catalog) simplify selection, replacement of legacy units and stocking of spare parts. Its broad refrigerant approval list helps systems transition towards lower‑GWP blends without changing the compressor platform.