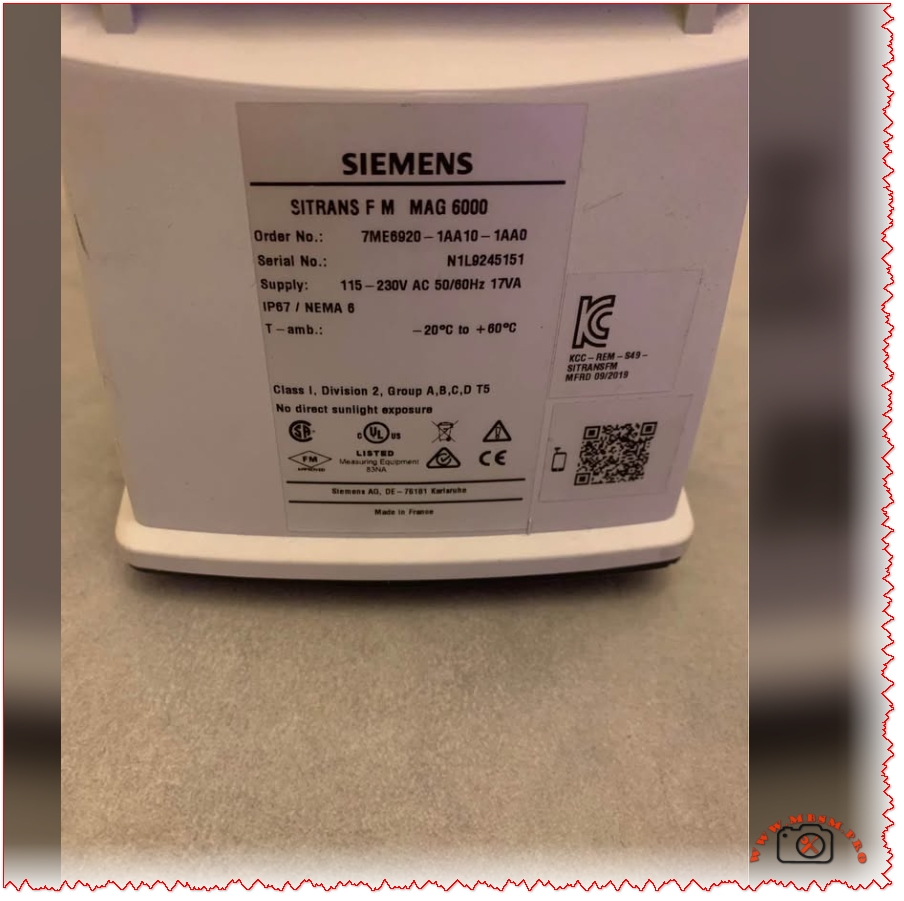

Siemens SITRANS FM MAG 6000, 7ME6920‑1AA10‑1AA0

Mbsmpro.com, Flowmeter Transmitter, Siemens SITRANS FM MAG 6000, 7ME6920‑1AA10‑1AA0, 115‑230V AC 50/60Hz, IP67 / NEMA 6, Class I Div.2, Batch Control, High‑Accuracy Electromagnetic Flow Measurement

Overview of the Siemens SITRANS FM MAG 6000 7ME6920‑1AA10‑1AA0

The Siemens SITRANS FM MAG 6000 with order number 7ME6920‑1AA10‑1AA0 is a microprocessor‑based electromagnetic flow transmitter engineered for high‑accuracy liquid measurement in industrial applications.

It combines IP67 / NEMA 6 protection, a back‑lit alphanumeric display, and wide‑range 115‑230 V AC 50/60 Hz supply for compact or wall‑mount installations in harsh environments.

Technical specifications and ratings

The table below summarizes the key technical data of the SITRANS FM MAG 6000 transmitter variant 7ME6920‑1AA10‑1AA0.

These characteristics make the SITRANS FM MAG 6000 transmitter a solid choice wherever reliable and repeatable volumetric flow measurement is required, from water distribution networks to process industry batching lines.

Functional features and exploitation in industrial systems

The MAG 6000 platform offers several core functions that go beyond basic flow indication.

- Instantaneous flow rate and totalizers: Two independent totalizers allow separate registration of forward and reverse flow or batching totals.

- Wide turndown and low‑flow cut‑off: Digital signal processing and high‑resolution measurement provide stable readings at both very low and very high velocities.

- Batch control and limit switching: Integrated batch controller with configurable relay outputs can start, stop, and fine‑tune dosing operations without an external PLC in smaller systems.

- Diagnostic and self‑verification: Built‑in self‑diagnostics and optional verification functions help operators detect coil faults, empty pipe alarms, configuration errors, and sensor problems early.

In daily exploitation this means a plant can use a single MAG 6000 transmitter as a measurement, supervisory, and basic control element, saving cabinet space and engineering time while maintaining metering‑class accuracy.

Comparison with other MAG transmitters and typical competitors

To clarify the position of the MAG 6000, the table compares it with the Siemens MAG 5000 transmitter and a generic compact electromagnetic flow transmitter of similar class.

Compared with the MAG 5000, the MAG 6000 offers tighter accuracy, extended communication options, and integrated batch functionality, making it more suitable for high‑value products and billing applications.

Against a typical compact magmeter, the MAG 6000 stands out with its rugged IP67 housing, richer diagnostics, and modular communications, which are important in large plants seeking long‑term reliability and easy integration.

Value comparison with alternative technologies

When deciding between the SITRANS FM MAG 6000 and other flow measurement technologies, engineers usually compare performance, installation constraints, and lifecycle cost.

Because the electromagnetic principle does not introduce obstruction or moving parts, the MAG 6000 solution usually offers lower total cost of ownership in water and wastewater plants compared with turbine or orifice systems, especially where solids or scaling are present.