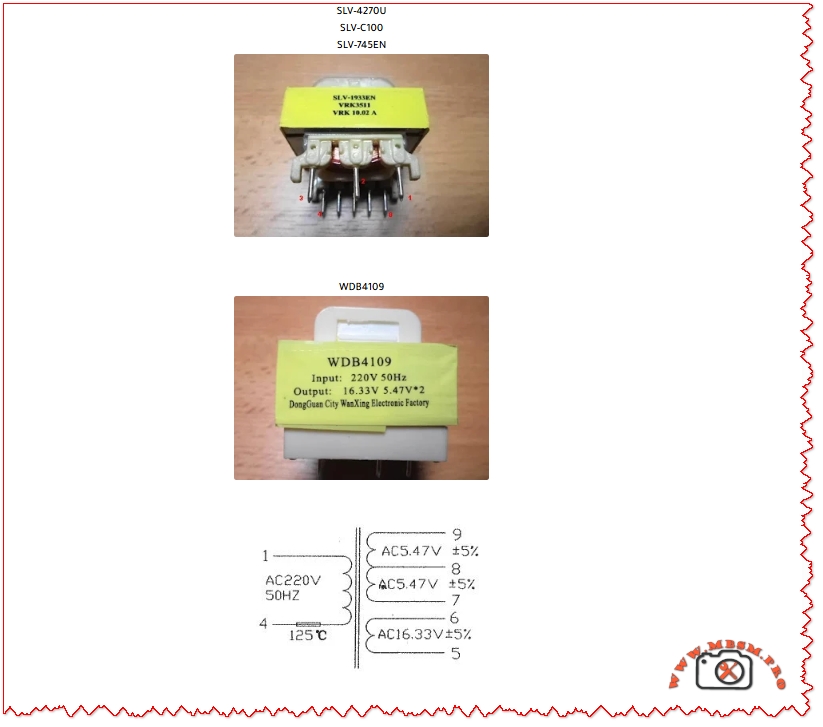

Transformer, WDB4109, 220V 50Hz, Microwave Standby Power

Mbsmpro.com, Transformer, WDB4109, 220V 50Hz, Microwave Standby Power, 16.33V, 5.47V×2, Linear Supply, Samsung Compatible, Replacement, Repair Guide

WDB4109 Microwave Standby Transformer Overview

The WDB4109 is a small linear power transformer designed for the standby and control circuits of domestic microwave ovens powered from 220 V – 230 V AC at 50 Hz.

It converts the mains input to one low‑voltage secondary of about 16.33 V AC and two identical low‑voltage outputs of 5.47 V AC used for logic, relays and display boards.

Key electrical characteristics

- Input: 220 V – 230 V AC, 50 Hz single phase.

- Output: one secondary winding 16.33 V AC ±5%, plus two 5.47 V AC ±5% windings (often specified as 16.33 V / 5.47 V ×2).

- Typical application: standby power transformer for Samsung and compatible microwave ovens, mounted on the main control PCB.

Pinout, wiring and application in microwave ovens

In most Samsung‑type control boards, the primary winding of the WDB4109 is connected directly across the 220 V mains through the line filter and protective thermal fuse.

The low‑voltage secondaries feed a rectifier and linear regulator stage, providing DC rails for the microcontroller, relay drivers, sensors and display modules, while remaining fully isolated from the mains.

Typical pinout description

- Primary side: two pins marked “AC220V 50Hz”, usually pins 1 and 4 on the housing legend.

- Thermal fuse: integrated in series with the primary and rated around 125 °C to protect from overheating.

- Secondary side:

Correct orientation is critical in repair work; technicians should always match the original PCB silkscreen and verify voltages under load with an isolated multimeter.

Technical tables and performance comparison

Table 1 – WDB4109 main specifications

Table 2 – WDB4109 vs generic microwave standby transformers

This comparison shows that the WDB4109 offers a rare triple‑output combination, making direct substitution with generic 12 V or 10.5 V transformers risky without redesigning the low‑voltage section.

Fault symptoms, testing and repair best practices

When the WDB4109 fails, common microwave symptoms include dead front panel, loss of clock and keypad response, or intermittent resetting when relays operate.

Technicians often discover an open primary winding or a blown internal thermal fuse after measuring infinite resistance between the primary pins, while the high‑voltage section and fuses remain intact.

Diagnostic and replacement guidelines

- Measure primary and secondary resistances with power disconnected; very high or infinite readings indicate open windings.

- Under isolation‑transformer protection, verify that secondary voltages reach approximately 16.33 V and 5.47 V AC under normal load, staying within ±5%.

- When sourcing a replacement, match input voltage, frequency, all secondary voltages and approximate VA rating, and prefer verified WDB4109 units from reputable component suppliers.

Using genuine or equivalent WDB4109 transformers reduces overheating risk and prevents over‑voltage on the control PCB, which can otherwise damage microcontrollers and relays.

Installation safety, market availability and alternative solutions

Repair of mains‑connected power components requires strict adherence to electrical safety standards, including discharge of high‑voltage capacitors and isolation from live circuits.

In many regions, WDB4109 transformers are sold individually or in packs on specialized electronic‑spares marketplaces, often described as “microwave computer board power transformer WDB4109 16.33 V / 5.47 V ×2.”

Availability and alternatives

- Online distributors and marketplace vendors list WDB4109 units as original or reclaimed parts from dismantled microwave ovens.

- If an exact WDB4109 is unavailable, technicians sometimes adapt transformers with similar triple‑output voltages, but this requires recalculating rectifier and regulator stages and is recommended only for experienced repairers.

Choosing an unsuitable alternative, even with close voltage ratings, can lead to overheating, excessive standby consumption or unstable logic supply, which negatively affects both performance and user safety.

Yoast SEO elements for this article

Focus keyphrase (≤191 characters)

WDB4109 microwave standby transformer 16.33V 5.47V×2, Samsung control board linear power supply, input 220V 50Hz, repair, replacement, pinout, specifications and troubleshooting guide

SEO title for Yoast

WDB4109 Microwave Standby Transformer 16.33V 5.47V×2 – Specs, Pinout, Repair & Replacement Guide | Mbsm.pro

Meta description for Yoast

Professional guide to the WDB4109 microwave standby transformer: 220V 50Hz input, 16.33V and 5.47V×2 outputs, pinout, testing methods, typical failures and safe replacement options for Samsung ovens.

Slug for Yoast

wdb4109-microwave-standby-transformer-16-33v-5-47v2-specs-repair

Tags (comma separated)

WDB4109, microwave standby transformer, 16.33V 5.47V×2, Samsung microwave repair, microwave control board power supply, transformer pinout, linear transformer fault, appliance spare parts, Mbsmgroup, Mbsm.pro, mbsmpro.com, mbsm

Excerpt (first 55 words)

The WDB4109 is a compact linear transformer used as the standby power source in many Samsung microwave ovens, converting 220 V – 230 V AC to 16.33 V and dual 5.47 V outputs for the control board. It is critical for powering the clock, keypad, relays and low‑voltage electronics safely.