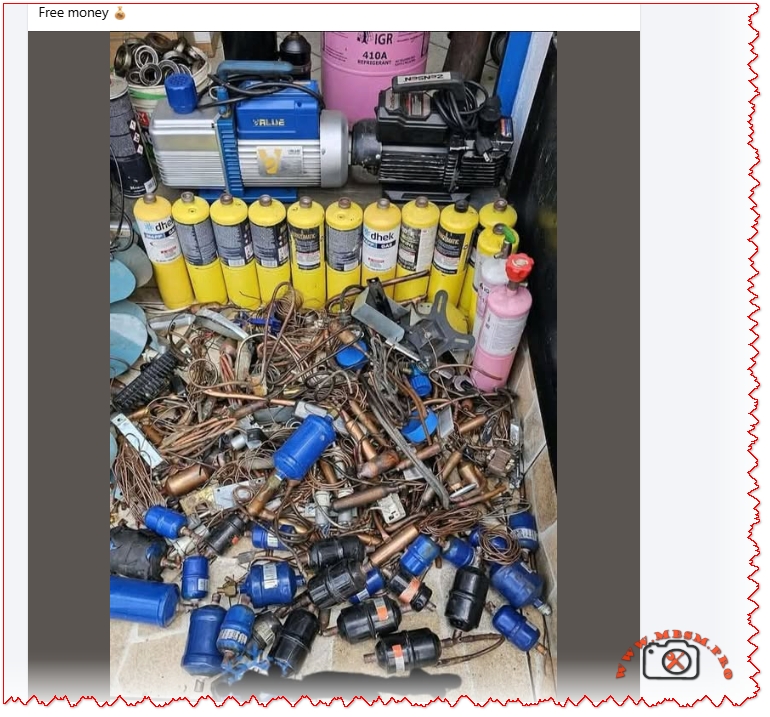

Free money Copper

Focus Keyphrase for Google SEO:

HVAC Refrigeration Scrap Recovery Copper Filter Drier Recycling Vacuum Pump R410A Maintenance Brazing Tools

SEO Title:

Mbsmpro.com, HVAC Tools and Scrap, Filter Drier, Copper, Vacuum Pump 2 Stage, R410A Cylinder, Mapp Gas, Maintenance, Recycling, Technical Data

Meta Description:

Comprehensive guide to HVAC refrigeration component recovery. Analysis of copper filter driers, vacuum pump specifications, brazing with MAPP gas, and sustainable recycling practices for technicians.

Slug:

hvac-refrigeration-scrap-recovery-copper-filter-drier-tools

Add Tag:

Copper Recycling, Filter Drier, HVAC Tools, Vacuum Pump, R410A, Brazing, Scrap Metal, Compressor Replacement, Maintenance, Mbsmgroup, Mbsm.pro, mbsmpro.com, mbsm

Excerpt:

In the world of refrigeration maintenance, a pile of discarded components tells a story of hard work and technical precision. Every replaced filter drier represents a saved compressor, and every vacuum pump represents a system brought down to perfect microns. This guide explores the technical value behind HVAC scrap and the essential tools used in the trade.

Mbsmpro.com, HVAC Tools and Scrap, Filter Drier, Copper, Vacuum Pump 2 Stage, R410A Cylinder, Mapp Gas, Maintenance, Recycling, Technical Data

When a refrigeration technician looks at a workshop floor, they don’t just see clutter; they see the lifecycle of thermodynamic systems. The accumulation of copper filter driers, the hum of high-performance vacuum pumps, and the distinct yellow canisters of brazing gas are the hallmarks of a busy season. Whether it is replacing a burnt-out compressor or performing a system flush, managing these materials is not just about waste—it is about resource recovery and engineering integrity.

The Hidden Value in Filter Driers

The most abundant item in any refrigeration scrap pile is often the filter drier. These components are critical for the health of a cooling system, acting as the kidney of the refrigeration cycle. They trap moisture, acid, and solid debris.

When scrapping or replacing these, it is vital to understand what they are made of. Most residential and light commercial driers have a copper shell, while larger industrial ones are steel. The “free money” aspect comes from the high-grade copper used in the spun copper driers. However, for the engineer, the value is in understanding why they failed.

Technical Composition of a Filter Drier

| Component | Material | Function | Recycling Potential |

| Shell | Spun Copper or Steel | Pressure containment | High (Copper is valuable) |

| Desiccant | Molecular Sieve (Zeolite) | Absorbs water/acid | None (Hazardous waste) |

| Screen | Stainless Steel / Brass | Filters particulates | Low |

| Connections | Copper | Brazing points | High |

Engineering Notice: Never reuse a filter drier. Once exposed to the atmosphere, the molecular sieve reaches saturation within minutes. A saturated drier releases moisture back into the system, creating hydrofluoric acid which destroys compressor windings.

The Heart of Evacuation: Vacuum Pumps

The presence of robust vacuum pumps, such as the dual-stage rotary vane pumps often seen in professional setups (like the blue “Value” series), indicates a commitment to deep vacuums.

A vacuum pump is not just an air mover; it is a dehydration tool. By lowering the pressure inside the refrigeration circuit below 500 microns, water boils off at room temperature and is exhausted as gas.

Comparison: Single Stage vs. Dual Stage Pumps

| Feature | Single Stage Pump | Dual Stage Pump (Recommended) |

| Ultimate Vacuum | ~75 Microns | ~15 Microns |

| Efficiency | Lower | High (Faster evacuation) |

| Application | Automotive / Small A/C | Refrigeration / Deep Freeze / R410A |

| Oil Sensitivity | Less sensitive | Requires clean oil for max performance |

Maintenance Tip: The oil in a vacuum pump is hygroscopic. If the oil looks milky or cloudy, it is saturated with moisture and cannot pull a deep vacuum. Change the oil immediately after every wet system evacuation.

Brazing and joining: Mapp Gas vs. Propane

For joining the copper lines of filter driers or compressors, standard propane is often insufficient due to its lower burn temperature. MAPP gas (Methyl Acetylene-Propadiene Propane) or “Map/Pro” replacements are the standard for field service.

Yellow cylinder gas burns significantly hotter than blue propane cylinders, allowing the technician to melt silver solder (15% to 45% silver content) rapidly without overheating the surrounding components.

- Propane Temperature in air: ~1,980°C (3,596°F)

- MAPP Gas Temperature in air: ~2,925°C (5,300°F)

Safety Protocol: When brazing near a Schrader valve or a service port, always remove the valve core or use a wet rag (heat sink) to prevent the rubber seals from melting.

R410A: Handling High-Pressure Refrigerants

The pink cylinders generally indicate R410A, a hydrofluorocarbon (HFC) refrigerant. Unlike the older R22, R410A operates at pressures approximately 60% higher. This dictates that all tools—manifold gauges, hoses, and recovery tanks—must be rated for these higher pressures.

Recovery and Recycling:

Venting refrigerant is illegal and unethical. Recovered R410A must be stored in DOT-approved recovery cylinders (usually gray with a yellow shoulder) and sent to reclamation facilities. The pink disposable tanks should strictly be used for charging, not recovery, as they lack overfill protection sensors.

Maximizing Copper Recovery (The “Free Money” Aspect)

For the technician looking to liquidate scrap, segregation is key. A mixed pile of steel and copper yields the lowest return.

- Cut the Ends: Use a tubing cutter to remove the copper capillary tubes or connection pipes from steel-bodied driers.

- Separate Brass: If there are expansion valves or service valves, separate the brass from the copper.

- Clean Copper: Tubing should be free of insulation (Armaflex) and heavy solder joints for the best grade classification (often called #1 Copper vs. #2 Copper).

Conclusion

The messy pile of copper, worn-out tools, and empty gas canisters is the byproduct of thermal comfort. For the expert, it represents a cycle of diagnosis, repair, and renewal. Whether you are recovering resources for recycling or evacuating a system to 200 microns, precision and material knowledge are your most valuable assets.

Exclusive Comparison: Filter Drier Types

This table assists in selecting the correct drier to replace the scrap units.

| Type | Application | Desiccant Blend | Direction |

| Liquid Line Drier | Placed after condenser | 100% Molecular Sieve (or blend) | Uni-directional |

| Suction Line Drier | Placed before compressor | High Activated Alumina (Acid cleanup) | Bi-directional (Heat Pump) or Uni |

| Spun Copper | Domestic fridges/freezers | Molecular Sieve beads | Uni-directional |