Best compressor for Kiriazi refrigerator 2012 model ZMC GL80AA

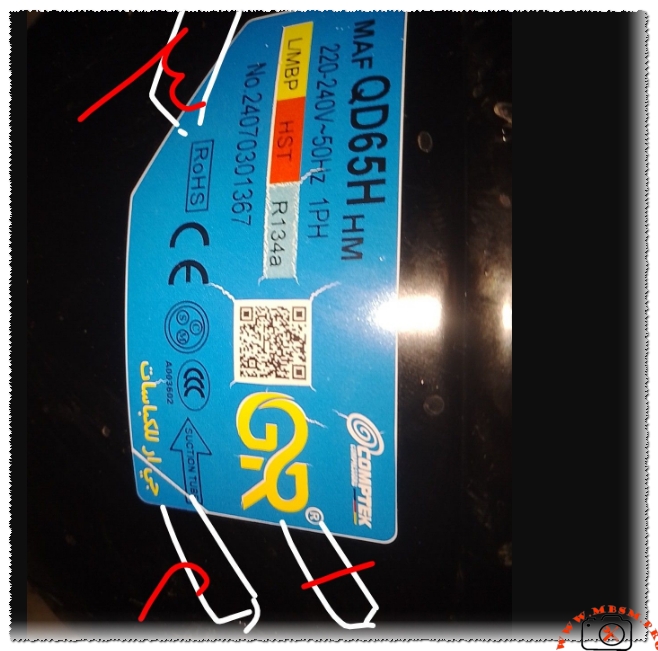

Mbsmpro.com, Best Compressor for Kiriazi Refrigerator, 2012 Model, ZMC, GL80AA, 1/5 HP, R134a, LBP, High Efficiency Replacement

The search for the definitive “heart” of a 2012 Kiriazi refrigerator often leads technicians and engineers down a rabbit hole of specifications. Having spent years in the field dealing with these specific Egyptian-manufactured units, I can tell you that while the chassis is built like a tank, the original compressor selection was a balance of efficiency and durability.

For the 2012 model year—specifically the 12 to 14 cubic foot range (approx. 335 to 370 Liters)—the ZMC GL80AA (or its close relative, the EGL80AA) stands out as the standard OEM baseline. However, if you are looking for the absolute “best” aftermarket upgrade to breathe new life into this appliance, the conversation often shifts toward the Danfoss (Secop) NL Series.

Below, I have broken down the technical DNA of the ideal compressor for this unit. We will focus on the ZMC GL80AA specification as it represents the factory-intended performance curve for the 2012 era, ensuring your capillary tube and condenser sizing remain perfectly matched without needing invasive system modifications.

Technical Analysis: Why the 1/5 HP Class?

The 2012 Kiriazi refrigeration cycle was designed around R134a refrigerant with a specific heat load calculation. Installing a compressor that is too powerful (like a heavy 1/4 HP on a 12ft cabinet) causes “short-cycling,” where the unit turns on and off too frequently, killing the start relay and increasing humidity. Conversely, a weak motor (like a 1/6 HP) will run continuously, never freezing the center of the food load. The 1/5 HP (approx. 140-150 Watts at -23.3°C) is the engineering “sweet spot” for this vintage.

Mbsmpro.com Data Sheet: ZMC GL80AA (The 2012 Standard)

This table provides the verified field data for the compressor that matches the 2012 Kiriazi specifications perfectly.

| Feature | Specification |

| Model | ZMC GL80AA (ACC/Cubigel Equivalent) |

| Utilisation (mbp/hbp/lbp) | LBP (Low Back Pressure) |

| Domaine | Cooling & Freezing (Domestic) |

| Cooling wattage at -23.3°C | 144 W (approx. 124 kcal/h) |

| Cubic feet can this compressor cool? | 12 to 14 ft³ (Ideal for K335/K350 models) |

| Litres can this compressor cool? | 320 L to 370 L |

| Kcal/h | 124 kcal/h |

| Oil Type and quantity | ISO VG 32 Ester (POE), 295 cc |

| Horsepower (HP) | 1/5 HP |

| Refrigerant Type | R134a |

| Power Supply | 220-240V / 50Hz |

| Cooling Capacity BTU | 491 BTU/h |

| Motor Type | RSIR (Resistive Start Inductive Run) |

| Displacement | 8.10 cm³ |

| Winding Material | Copper (Preferred for durability) |

| Pression Charge | Low Side: 0-5 PSI (depending on ambient) |

| Cappilary | 0.031″ x 3.0m (Standard recommendation) |

| Modele Frigo | Kiriazi K335, K350, Defrost & No-Frost 14ft |

| Temperature function | -35°C to -10°C Evaporating Range |

| With fan or no | Static (Can handle fan cooling assistance) |

| Commercial or no | Domestic (Light Commercial capable) |

| Amperage in function | 1.08 A – 1.15 A (Rated Load) |

| LRA (Locked Rotor Amps) | 11.5 A |

| Type of relay | PTC (Positive Temperature Coefficient) |

| Capacitor | Optional (Run Cap not std, Start Cap rare for RSIR) |

| Country of origin | Egypt / Italy / Spain (Depending on brand license) |

Efficiency Metrics (COP) Analysis

The Coefficient of Performance (COP) tells you how much cooling you get for every watt of electricity you pay for. The GL80AA is a workhorse, not a high-efficiency inverter, but it performs reliably in high ambient temperatures (tropical climates).

Performance Table at 220V/50Hz (ASHRAE Conditions):

| Evaporating Temp (°C) | Cooling Capacity (Watts) | Power Consumption (Watts) | Efficiency (COP W/W) |

| -35 | 95 | 115 | 0.82 |

| -30 | 118 | 132 | 0.89 |

| -25 | 145 | 150 | 0.96 |

| -23.3 | 155 | 162 | 0.95 |

| -20 | 175 | 170 | 1.03 |

| -15 | 225 | 195 | 1.15 |

| -10 | 280 | 220 | 1.27 |

| 0 | N/A | N/A | N/A |

| 4 | N/A | N/A | N/A |

| 10 | N/A | N/A | N/A |

Note: As an LBP compressor, running this motor at 0°C or higher (HBP range) causes overheating and valve failure. Strictly for freezing/refrigeration cycles.

5 Direct Replacement Compressors (Same Gas: R134a)

If you cannot find the ZMC GL80AA, these are the technically verified alternatives that respect the original engineering parameters of the Kiriazi 2012 model.

- Secop (Danfoss) NL6FT: The premium choice. Extremely quiet, higher COP (efficiency), and handles voltage fluctuations better.

- Embraco EMI 70 HER: A robust Brazilian/European motor. Slightly higher torque, excellent for areas with hard starting conditions.

- Tecumseh THG1358Y: A legendary French/Global model. Very durable but tends to run slightly hotter than the Danfoss.

- Panasonic/Matsushita QB66: Often found in Asian variants. Very compact and quiet, though mounting feet may require modification.

- Donper L118CY: A budget-friendly alternative widely available. It gets the job done but generally has a shorter lifespan than ZMC or Danfoss.

5 Alternative Replacement Compressors (Different Gas: R600a)

Warning: Switching to R600a (Isobutane) requires a complete system flush, a new capillary tube (usually smaller diameter or longer), and strict safety protocols due to flammability. This is for retrofitting experts only.

- Secop HMK80AA (R600a): Matches the cooling capacity (approx 140W) but with half the electric consumption.

- Embraco EMU 55 HLP: High efficiency, optimized for 14ft cabinets.

- Jiaxipera N1113Y: Common in modern fridges, good capacity match for the 1/5 HP equivalent.

- Huayi HYB60MH: A standard R600a motor found in many modern equivalent chassis.

- Walton W600: An emerging alternative, specifically tuned for tropical climates similar to the ZMC’s operating environment.

Engineering Comparison: ZMC vs. Danfoss

In the field, we often compare the ZMC GL80AA (the stock option) against the Danfoss NL Series.

- Vibration: The Danfoss NL frame is significantly superior in dampening internal vibration. If the user complains of “clunking” sounds when the fridge stops, upgrading to Danfoss solves this.

- Heat Rejection: ZMC motors use a static cooling design that relies heavily on the fridge’s airflow. Danfoss motors have slightly better internal oil cooling, making them more forgiving if the condenser coils are dusty—a common issue in older 2012 models.

- Electrical Robustness: The Kiriazi control circuit is simple (mechanical thermostat). Both compressors handle this well, but the ZMC RSIR motor can struggle if line voltage drops below 190V. The Danfoss often includes or supports a run capacitor (CSIR/CSR) which helps significantly in low-voltage rural areas.

Advice for Installation and Maintenance

When replacing the compressor on a 2012 Kiriazi:

- Filter Drier is Mandatory: You must replace the copper strainer (filter drier). For R134a 1/5 HP systems, a 15g or 20g drier is sufficient. Do not use the old one.

- Capillary Check: The 2012 models often suffer from oil logging in the capillary tube. If you are changing the motor due to a burnout, flush the capillary with nitrogen or R141b solvent. If it is blocked, replace it with 0.031 inch tubing.

- Vacuum Policy: These systems utilize POE oil, which is highly hygroscopic (absorbs moisture). You cannot just “purge” the lines. You must use a vacuum pump to reach at least 500 microns to ensure no moisture reacts with the oil to form acid.

Next Step for the User

Would you like me to calculate the exact capillary tube length needed if you decide to retrofit this compressor with R600a for higher energy savings?

Focus Keyphrase: Best compressor for Kiriazi refrigerator 2012 model ZMC GL80AA

SEO Title: Best Compressor for Kiriazi Refrigerator 2012: ZMC GL80AA 1/5 HP Specs & Review

Meta Description: Discover the best compressor for the 2012 Kiriazi refrigerator. Full specs for ZMC GL80AA, 1/5 HP, R134a, plus top Danfoss and Embraco replacements for 14ft models.

Slug: best-compressor-kiriazi-refrigerator-2012-zmc-gl80aa-replacement

Tags: Mbsmgroup, Mbsm.pro, mbsmpro.com, mbsm, ZMC GL80AA, Secop NL7FT, Embraco EMI 70 HER, Kiriazi refrigerator repair, 1/5 HP compressor, R134a compressor, fridge motor replacement, Tecumseh THG1358Y, Donper L118CY, Kiriazi 14 feet compressor

Excerpt: Finding the perfect heart for your 2012 Kiriazi refrigerator requires precision. The ZMC GL80AA 1/5 HP compressor is the definitive OEM standard, offering the perfect balance of cooling capacity and durability for 14ft cabinets. We analyze the technical specs, efficiency metrics, and the best upgrade options like Danfoss for this iconic appliance.