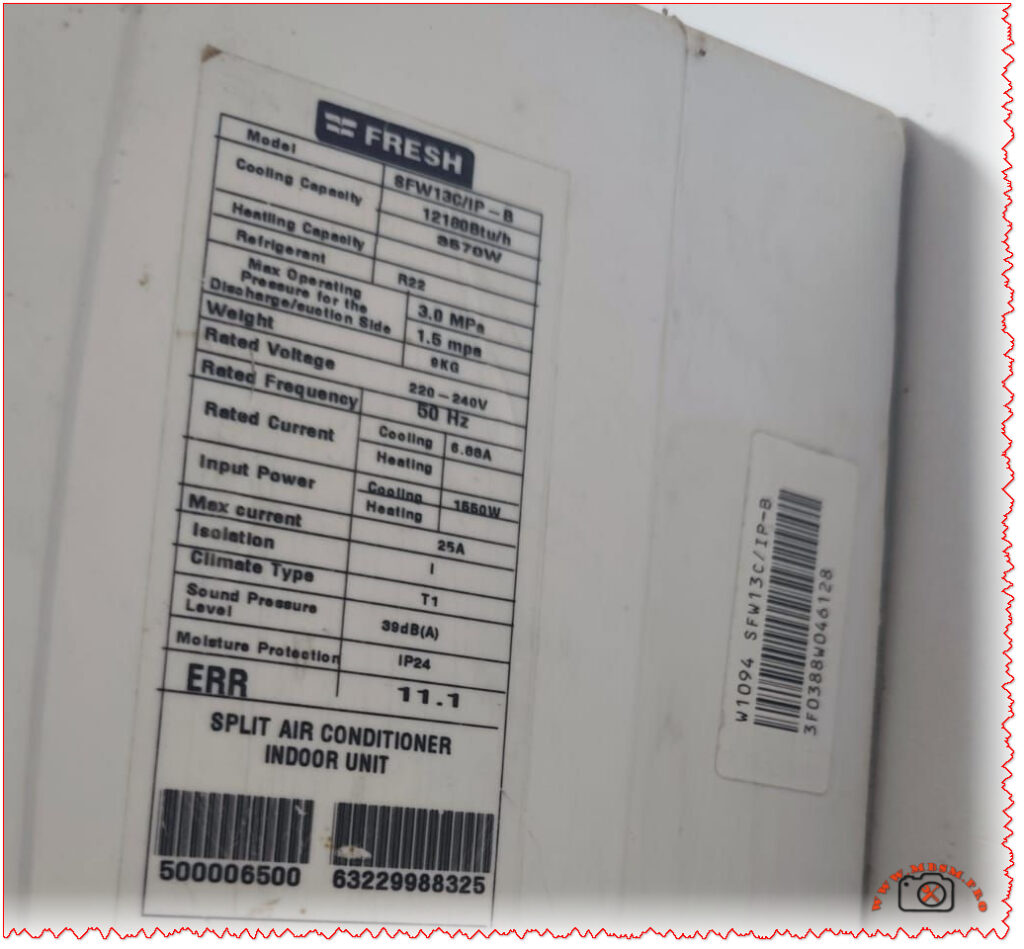

Fresh SFW13C1P‑B Split Air Conditioner

Fresh SFW13C1P-B Split Air Conditioner: Technical Label, Specifications, and Error 11.1 Guide

The Fresh SFW13C1P-B split air conditioner is a 1.5 HP cooling‑only indoor unit designed for 220–240 V residential applications, with a cooling capacity around 12,000 BTU/h and R22 refrigerant. Its nameplate also references the diagnostic code ERR 11.1, which technicians commonly associate with serial communication faults between indoor and outdoor units on similar split systems.

Nameplate data overview

The identification label on the Fresh SFW13C1P-B indoor unit groups the key electrical and operating data needed for installation, commissioning, and service.

- Model family: SFW13C series, 1.5 HP, cooling‑only split air conditioner.

- Typical application: Small to medium rooms (about 12–18 m² depending on climate and insulation).

- Refrigerant: R22 on legacy units in this series, with specified maximum operating pressures for high and low sides.

Fresh SFW13C1P-B basic specifications

Electrical and operating characteristics

The label on the SFW13C1P‑B provides detailed electrical data that help installers size breakers, cables, and protection devices correctly.

- Rated voltage 220–240 V, 50 Hz single‑phase with electronic inverter control on associated outdoor units in the SIFW/SFW families.

- Rated and maximum currents are specified (often around 6–8 A running and 20–25 A max), guiding breaker choice and cable sizing.

- Input power on cooling is in the 1.5 kW class for a 1.5 HP Fresh split, which matches catalog data for SIFW13C‑IP and SFW13C series.

Indicative electrical table for 1.5 HP Fresh SFW13C series

ERR 11.1 on Fresh SFW13C1P-B

The nameplate of this indoor unit explicitly lists “ERR 11.1”, indicating that self‑diagnostic communication is part of the design.

- On many inverter split systems, error 11 or 11.1 corresponds to a serial communication error between indoor and outdoor units (loss or corruption of signal on the interconnecting terminals).

- Service manuals for comparable brands describe error 11 as forward or reverse transfer serial communication failure, often triggered when the outdoor PCB does not properly receive the indoor control signal for 10 seconds or more.

Typical causes associated with error 11 / 11.1

Professional troubleshooting approach

Professional technicians treating a Fresh SFW13C1P‑B that displays ERR 11.1 can follow a methodical process inspired by standard inverter AC service instructions.

- Reset and verify supply

- Inspect communication wiring

- Measure serial signal

- Service documentation for similar systems specifies that the AC serial signal between designated terminals should swing within an expected voltage window (for example, 30–130 V AC) during operation; abnormal readings indicate PCB or wiring faults.

- During measurement, verify that fan motors and relays do not induce excessive noise on the same harness.

- Evaluate PCBs and external causes

User‑oriented best practices

End users operating a Fresh SFW13C1P‑B split unit can reduce the risk of error codes and extend system life by following a few simple best practices derived from documentation of modern Fresh air conditioners.

- Maintain clean indoor filters to preserve airflow and reduce strain on the refrigeration circuit and electronics.

- Avoid repeatedly cycling power from the main breaker, as frequent restarts stress inverter components and communication circuits; instead use the remote control for routine on–off operations.

- If error 11.1 appears repeatedly after a full power reset, contact qualified HVAC service instead of attempting to rewire the communication cable.