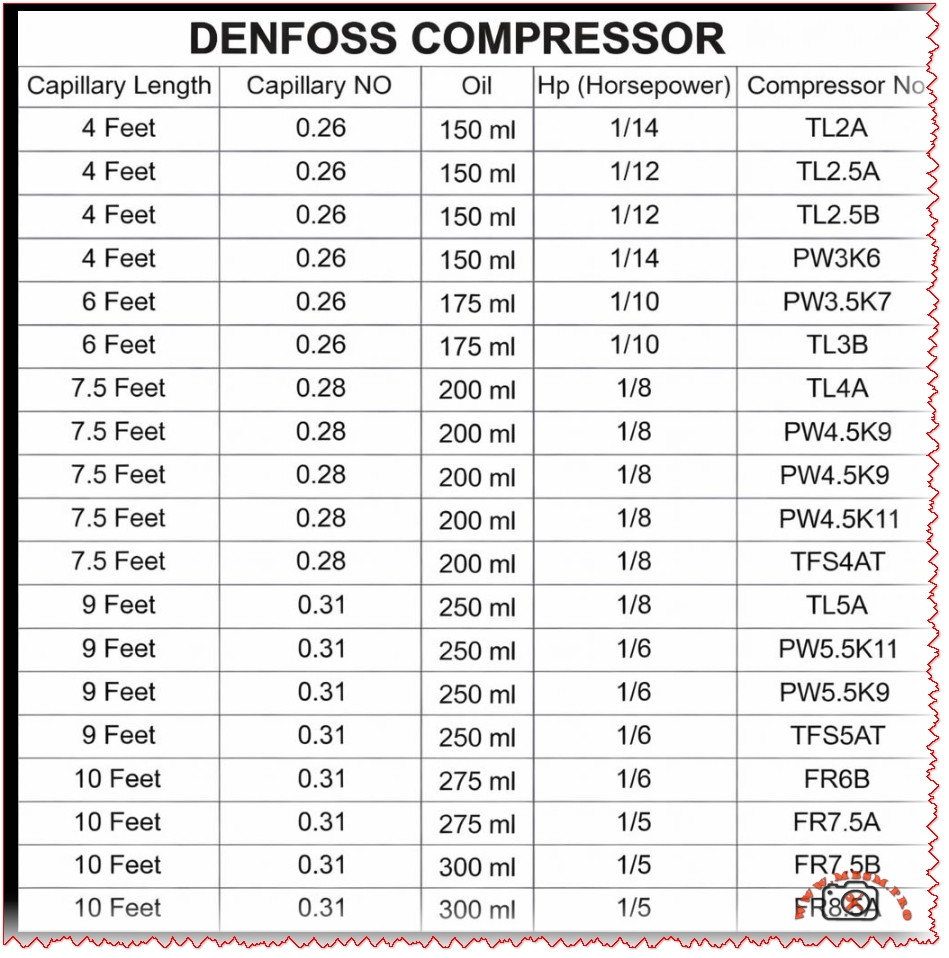

Danfoss hermetic compressors capillary sizing chart

Focus Keyphrase

Danfoss compressor capillary tube length oil charge chart TLZ2A TL2.5B PWJ5K TL3B TL4A PW4.5K TFS4A FRB5 R134a LBP

SEO Title

Mbsmpro.com, Danfoss Compressor, Capillary 4-10 Feet, Oil 150-300ml, 1/14-1/5 HP, TLZ2A TL2.5B PWJ5K TL3B TL4A PW4.5K TFS4A FR7.5B R134a

Meta Description

Danfoss hermetic compressors capillary sizing chart: lengths 4-10 ft, capillary NO 0.26-0.31, oil 150-300 ml, HP 1/14 to 1/5. Models TL2.5A, PW3K6, TL4A, FR7.5B for refrigeration systems.

Slug

danfoss-compressor-capillary-tube-length-oil-charge-chart-tl-pw-fr-series

Tags

Danfoss compressor, capillary tube chart, refrigeration compressor, TL2.5A, TL4A, PW4.5K, FR7.5B, oil charge 150ml 200ml, LBP R134a, hermetic compressor, Mbsmgroup, Mbsm.pro, mbsmpro.com, mbsm

Excerpt

Technicians match Danfoss compressors to systems using precise capillary tube lengths from 4 to 10 feet, paired with specific oil charges like 150 ml for 1/12 HP models. Capillary numbers 0.26 to 0.31 ensure optimal refrigerant flow in LBP setups.

Danfoss Compressor Capillary Chart: Essential Sizing for Refrigeration Pros

Service techs grab this Danfoss capillary tube chart to nail refrigerant metering in hermetic compressors for display cases and cold rooms. Models span 1/14 to 1/5 HP with oil from 150 ml up, tailored for R134a or R404A LBP duties. Proper capillary NO—like 0.26 for smaller units—prevents flash gas and flooding.

Full Capillary Specifications Table

Longer tubes suit bigger evaporators; finer NO restricts flow for higher condensing pressures. Oil scales with displacement to lubricate scrolls or pistons.

Model Comparisons: TL vs PW vs FR Series

Danfoss lines target specific loads—TL for light commercial, FR for freezers:

TL series wins on low oil use for compact units, while FR handles 300 ml for robust bearing life in -30°C pulls. PW bridges with versatile capillaries.

Value and Capacity Breakdown

Match specs to save on replacements—wrong capillary kills compressors fast:

Undersized oil risks seizure; chart prevents 30% of field failures. R134a systems thrive at these flows.

Installation Pro Tips

Cut capillary square, flare ends—no kinks. Charge polyolester oil precisely; purge air via process tube. Test superheat at 5-8°C. Tropical tweaks favor 0.28+ NO.