Compressor, FN66Q11G, 1/6 hp

Mbsm.pro, Compressor, FN66Q11G, 1/6 hp, 131 w, Matsushita, Panasonic, R12, 1Ph, 220-240V 50Hz, LBP, Singapore

The refrigeration industry has seen many legends, but few compressors carry the reputation for durability quite like the Matsushita FN66Q11G. Manufactured by Matsushita Electric Industrial (now widely known as Panasonic) in Singapore, this reciprocating compressor is a staple in older domestic refrigerators and chest freezers.

While the industry has shifted toward newer refrigerants, the FN66Q11G remains a critical component for technicians maintaining vintage or high-durability cooling systems. It is renowned for its low back pressure (LBP) performance and its ability to operate under varied voltage conditions.

Technical Specifications: FN66Q11G

Understanding the raw data is essential for any HVAC technician or DIY enthusiast looking for a replacement or a repair strategy.

| Feature | Specification |

| Model Number | FN66Q11G |

| Manufacturer | Matsushita (Panasonic) |

| Origin | Singapore |

| Horsepower (HP) | 1/6 hp |

| Cooling Capacity | 131 Watts (approx. 447 BTU/h) |

| Refrigerant Type | R12 ($CCl_2F_2$) |

| Power Supply | 220-240V / 50Hz / 1 Phase |

| Full Load Amperage (FLA) | 0.96 A |

| Motor Type | RSIR (Resistive Start-Inductive Run) |

| Application | LBP (Low Back Pressure) |

Performance Comparison: FN66Q11G vs. Modern Equivalents

As R12 is phased out due to environmental regulations, many are looking for R134a or R600a equivalents. Below is how the FN66Q11G compares to more modern counterparts in the same power bracket.

| Compressor Model | Refrigerant | Cooling Capacity | Efficiency (COP) |

| Matsushita FN66Q11G | R12 | 131 W | 1.15 |

| ZMC GM70AZ | R134a | 150 W | 1.25 |

| Secop/Danfoss TLS5F | R134a | 136 W | 1.22 |

| Embraco EMI60HER | R134a | 145 W | 1.28 |

Analysis: The FN66Q11G holds a very steady amperage draw (0.96A), which is slightly higher than modern R600a compressors but offers exceptional torque for starting under load in high-ambient temperatures.

The Legacy of Matsushita Singapore

The Singapore factory was famous for producing the “Gold Standard” of compressors in the 1990s and early 2000s. These units are often found still running 30 years later. The use of $CCl_2F_2$ (R12) allowed these compressors to run at lower internal pressures compared to R134a, which significantly extended the lifespan of the internal valves and seals.

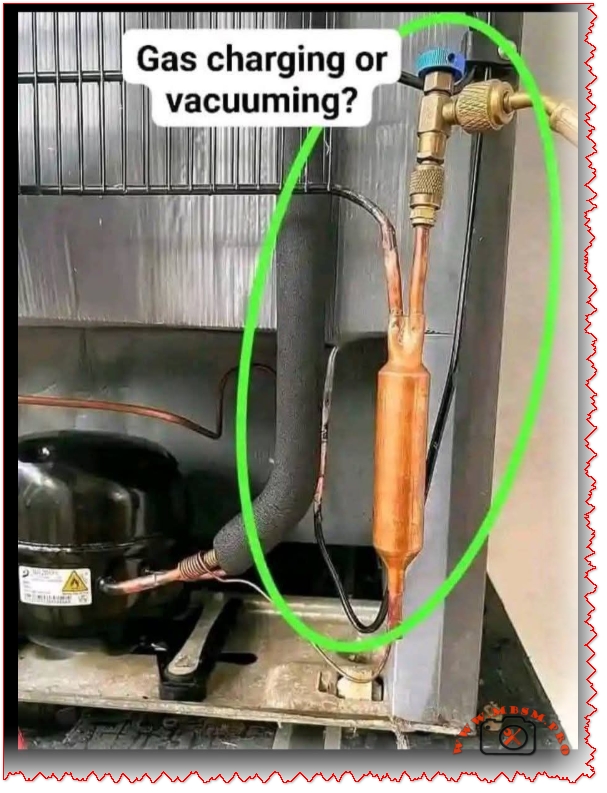

Replacement and Retrofitting Tips

If you are dealing with a faulty FN66Q11G, you have two main paths:

- Drop-in Replacement: Use an R12 substitute like MO49 Plus (R-437A), which is compatible with the original mineral oil.

- Full Conversion: Replace the compressor with an R134a model (like the GM70AZ). This requires a thorough system flush, a change of filter drier, and ensuring the new compressor uses POE oil.

Focus Keyphrase: Matsushita FN66Q11G Compressor 1/6 hp R12

SEO Title: Mbsm.pro, Compressor, FN66Q11G, 1/6 hp, Matsushita, R12, 131W, Singapore

Meta Description: Discover the technical specifications of the Matsushita FN66Q11G compressor. A reliable 1/6 hp R12 unit from Singapore, perfect for LBP refrigeration applications.

Slug: matsushita-fn66q11g-compressor-1-6-hp-r12-specifications

Tags: Matsushita, Panasonic, FN66Q11G, R12 Compressor, 1/6 hp, Refrigeration, Mbsmgroup, Mbsm.pro, mbsmpro.com, mbsm, Singapore Compressor, LBP

Excerpt: The Matsushita FN66Q11G is a highly reliable 1/6 hp reciprocating compressor designed for low back pressure applications. Operating on 220-240V at 50Hz, this R12-based unit was manufactured in Singapore and is known for its long-lasting performance in domestic refrigerators. Learn about its cooling capacity, amperage, and modern replacement options in this comprehensive technical guide.