LG T1387NEHVE 13.2 kg Smart Inverter, Washing Machine

LG T1387NEHVE 13.2 kg Smart Inverter Top Load Washing Machine Nameplate: What Every Technician Should Read

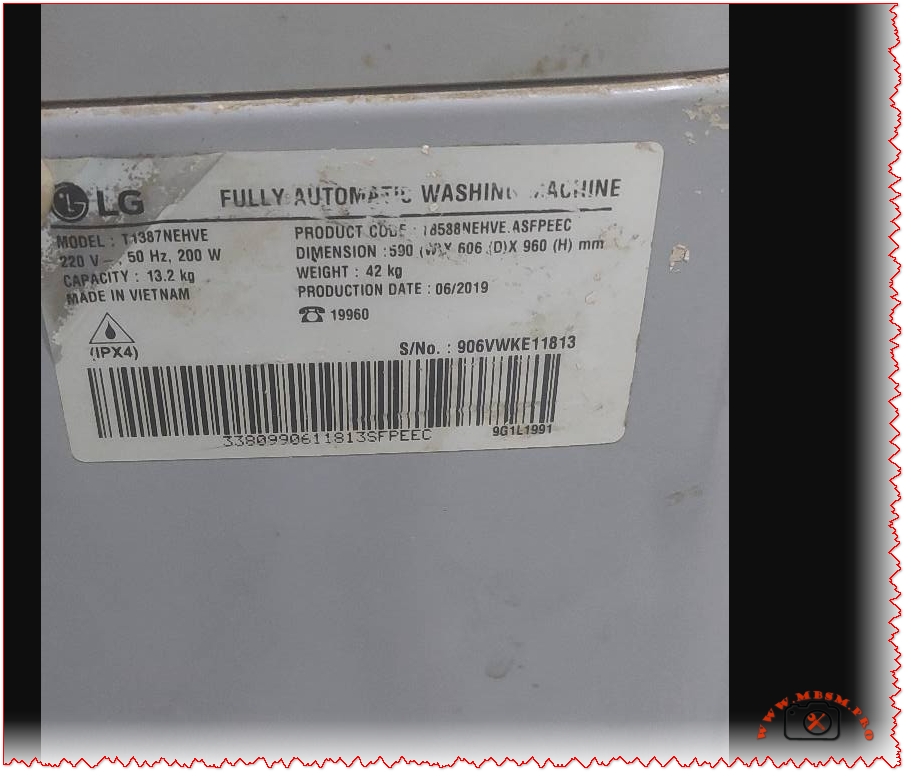

The label fixed to the side of the LG T1387NEHVE washing machine is more than a simple sticker; it is a compact technical identity card that tells you exactly what this appliance can do, how it should be powered, and when it was manufactured. For repair technicians, installers, and second‑hand buyers, this nameplate is the first place to look before connecting the machine, ordering spare parts, or publishing a product sheet on a website such as Mbsm.pro or Mbsmgroup.

Technical identity of the LG T1387NEHVE

The image shows a white identification label on a silver cabinet with the LG logo followed by the description Fully Automatic Washing Machine and the model code T1387NEHVE. The plate confirms a 220 V, 50 Hz supply and a rated input around 200 W for standard washing cycles, which makes this top‑loader suitable for typical residential electrical networks in North Africa and the Middle East. The capacity printed on the label is 13.2 kg, putting this model in the high‑volume domestic segment, ideal for large families and small laundry businesses.

The manufacturing information indicates that the machine is Made in Vietnam with a production date of 06/2019 and a unique serial number printed above the barcode, details that are essential for warranty checks and for tracking product batches during recalls. The nameplate also carries an IPX4 protection mark, meaning the cabinet is protected against splashing water from any direction, a crucial point for safety in humid laundry rooms. Next to the compliance icons, the product code format (like 1S88NEHVE.ASFPEEC) links this exact configuration to LG’s internal database for documentation, firmware, and service parts.

Main specifications and dimensions

Behind this modest label there is a full‑size 13.2 kg smart inverter top‑load washer with modern LG technology. Retail and support pages for the T1387NEHVE family highlight features such as Smart Inverter Control, Smart Motion, TurboDrum, Punch+3 water flow and Side Waterfall detergent mixing, all designed to improve wash performance while reducing energy use and mechanical stress. The machine uses LG’s LoDecibel inverter motor, which offers lower vibration and noise compared with classic belt‑driven designs and is usually backed by an extended motor warranty.

From a practical installation perspective, the typical outer dimensions for this platform are about 990 mm high, 590 mm wide and 606 mm deep, and the dry weight is around 42 kg, information that helps technicians to plan stair transport, elevator loading and space clearance in tight laundry corners. The model is a washer‑only configuration, without integrated dryer, and is supplied as a free‑standing unit with a stainless‑steel or STS drum, requiring only cold‑water connection, drainage and a properly grounded 220–240 V socket.

Why the nameplate matters for service and resale

For field technicians, reading the nameplate before any intervention is a basic but critical habit. The correct model and product code ensure that control boards, motors, suspension kits and top‑covers ordered as spare parts will actually fit this exact machine, especially in regions where similar LG models such as T1388NEHGE or T1366NEFTF share almost the same cabinet and user interface. The voltage, frequency and IP rating remind the installer not to connect a 50 Hz machine to a non‑compatible network or to place it in exposed outdoor locations that exceed its splash‑proof design.

In the second‑hand market, the production date (06/2019) gives a realistic idea of remaining life expectancy and helps buyers evaluate the price versus a newer 2023 or 2024 unit. Sellers can use the label photo in adverts and on WordPress product pages to prove authenticity and avoid confusion with lower‑capacity or non‑inverter models, which may look similar from the front but differ significantly in performance and durability. For online catalogues like Mbsmgroup and mbsmpro.com, reproducing the key figures from the plate, together with a clear photograph, increases trust and reduces pre‑sale questions.

Specification table for WordPress article

Useful image and PDF resources for your article

For a richer WordPress article, you can safely embed or link to a few illustrative media and documents related to this LG top‑load platform:

- High‑resolution product photos of LG smart inverter top‑load washers in the same family (13 kg class) are available on LG regional sites; for example the official gallery for similar 13 kg top‑load models such as the T1366NEFTF shows clear cabinet, control panel and drum views.

- Detailed commercial images and lifestyle shots of a 13–13.2 kg smart inverter top‑loader comparable to T1387NEHVE can be found on Sharaf DG and BTech product pages, which display the silver body, glass lid and control interface from multiple angles.

For technical documentation and catalog PDF links you can add to your post:

- LG’s support portal for the T1387NEHVE series provides user manuals and sometimes quick‑start guides under similar codes like T1388NEHVE; the manual hosted on Manua.ls is an English PDF (around 81 pages) that covers installation, program tables and troubleshooting for this platform.

- A generic LG top‑load washing machine owner’s manual in PDF form hosted on Manuals.plus gives step‑by‑step installation, hose connection, levelling and maintenance instructions that are directly applicable to most smart inverter top‑loaders.

- Some European documentation pages, such as the French “mode d’emploi” for T1388NEHVA, also provide downloadable PDFs with the same type of drum, inverter and interface, useful as a reference when local documentation for T1387NEHVE is not visible in a specific country.

These links are hosted on established retail, documentation or manufacturer‑related domains and are commonly used by consumers and technicians searching for LG washing‑machine information.