Electrostar 16 foot refrigerator 1/6 HP compressor 125W top freezer Mbsmgroup

Electrostar 16 foot refrigerator 1/6 HP compressor 125W top freezer Mbsmgroup

Electrostar 16‑Foot Refrigerator: Reliable Cooling With Efficient Compressor Power

The Electrostar 16‑foot refrigerator remains a practical choice for families who want robust cooling, straightforward controls and serviceable components rather than complex smart features. With a capacity around 315–330 liters and a compact footprint, it suits medium‑size kitchens while its small‑horsepower compressor keeps electricity consumption under control in hot climates.

Design, capacity and layout

Electrostar positions this 16‑foot series in the standard top‑freezer category, giving households a familiar layout that is easy to organize and clean. The cabinet typically offers roughly 315–330 liters of gross capacity, split between a top freezer for frozen food and a larger refrigerator section for fresh produce, drinks and daily ingredients.

- Adjustable wire or glass shelves let users reconfigure the interior for tall pots, trays or beverage bottles as needed.

- A full‑width vegetable crisper maintains higher humidity for fruits and vegetables, limiting dehydration over long storage periods.

- Door balconies provide space for sauces, jars and large bottles so that the main shelves stay free for bulkier items and prepared dishes.

Cooling system and compressor power (HP & W)

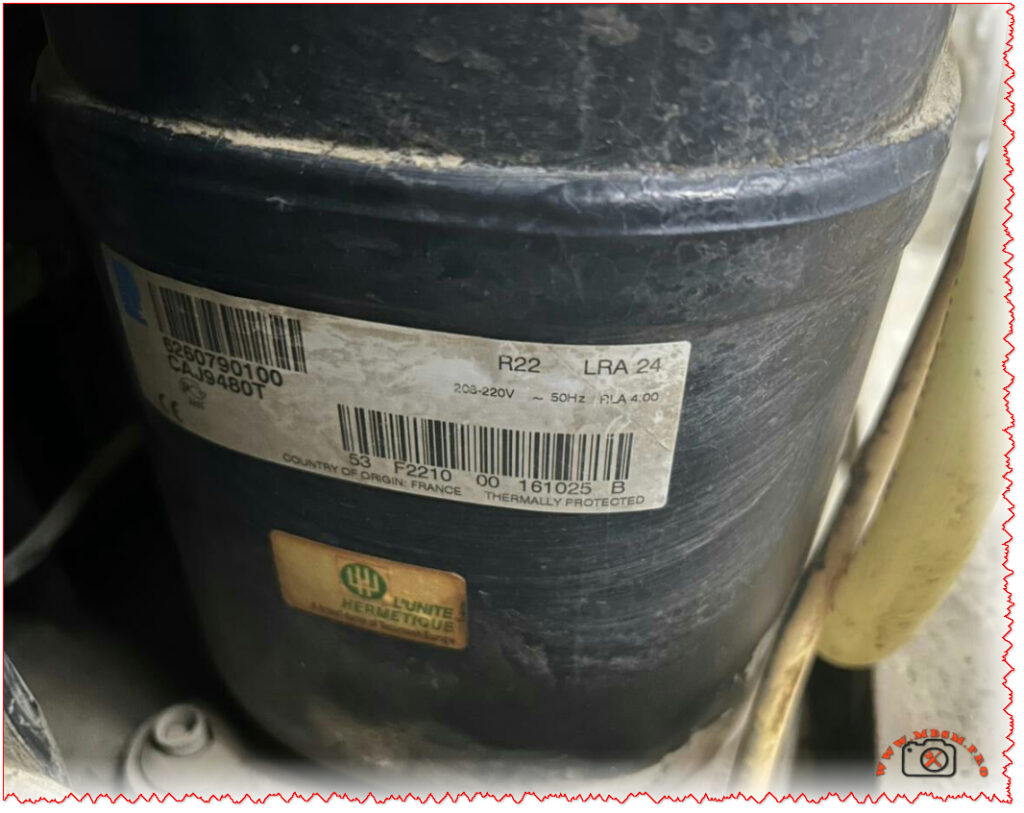

Most 16‑foot Electrostar models are offered in both defrost and No‑Frost versions, but in both cases the “heart” of the system is a low‑horsepower hermetic compressor sized for domestic use. Domestic compressor selection charts show that refrigerators in the 9–13 cubic‑foot (around 283–370 liter) range are normally matched with compressors in the 1/6 to 1/5 horsepower class, consuming about 120–150 watts at rated conditions.

- A typical 1/6 HP refrigerator compressor corresponds to roughly 120–130 W electrical input, giving enough capacity for a 16‑foot top‑freezer cabinet when paired with an efficient evaporator and insulation package.

- Independent wattage studies for 16–20 cubic‑foot top‑freezer fridges show average running power between 100 and 400 W depending on design and age, placing a modern Electrostar 16‑foot model toward the lower end of that span when the thermostat cycles the compressor on and off.

- Some Electrostar variants use branded compressors such as Panasonic, chosen for quieter operation and better efficiency in high‑ambient environments.

Technical snapshot

Everyday performance and reliability

Electrostar’s 16‑foot refrigerators are built for continuous operation in regions where high ambient temperatures put extra stress on compressors and condensers. The relatively small 1/6 HP‑class compressor may sound modest, but in a well‑insulated cabinet it provides ample cooling capacity while keeping noise and energy bills under control for most households.

- Mechanical thermostat controls make it simple for users to adjust internal temperatures without dealing with complex digital menus, and they are easy for technicians to diagnose and replace.

- Service networks in many Arab and North‑African markets stock compatible compressors, starting components and thermostats, which reduces downtime in case of failure and extends the working life of older units.

- When paired with good ventilation around the condenser and regular cleaning, the compressor can run for many years with stable suction and discharge pressures, even under heavy daily usage.

Maintenance tips to protect the compressor

Proper maintenance does not just improve hygiene; it also directly protects the small‑horsepower compressor from unnecessary strain and overheating.

- Keep at least several centimeters of clearance around the back and sides of the refrigerator so that condenser coils can reject heat effectively, preventing the compressor from running at high head pressure for long periods.

- For defrost models, manually defrost the freezer whenever frost thickness exceeds about 3–5 mm, since thick ice forces the compressor to run longer cycles to pull down temperature.

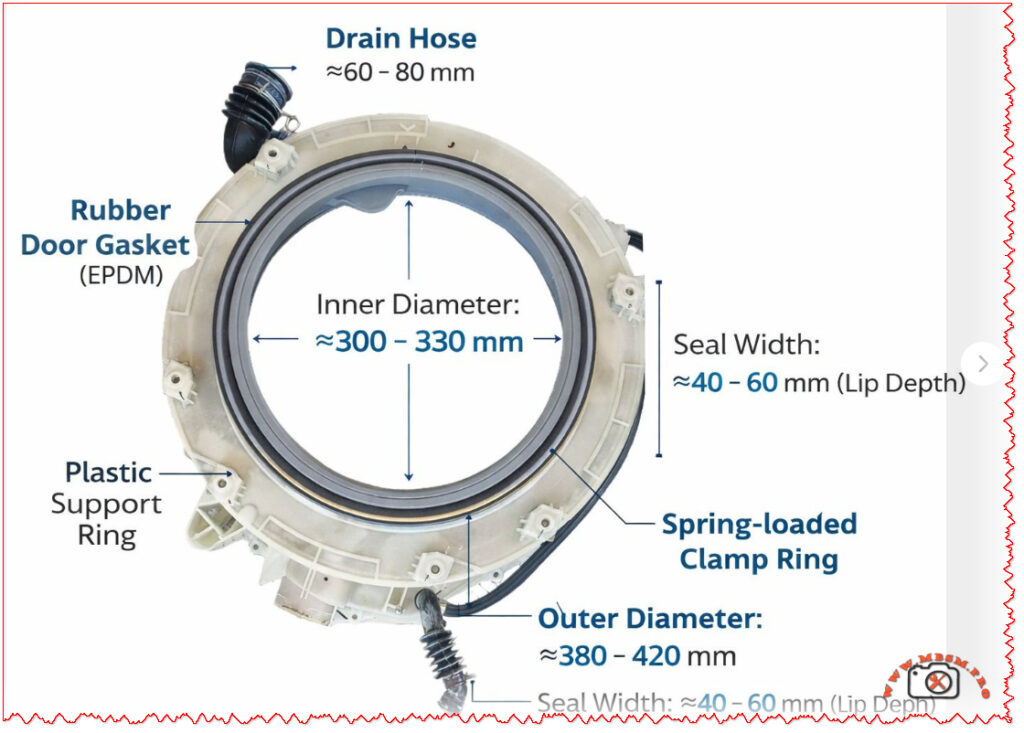

- Check door gaskets regularly for cracks or gaps; a poor seal allows warm air infiltration, leading to more frequent compressor starts and higher electricity use.

Helpful external resources

Technicians and advanced users who want deeper technical data can turn to independent references and brand‑agnostic manuals.

- A general household refrigerator user manual in PDF format explains compressor operation, wattage ratings, thermostat settings and recommended clearances that apply to most top‑freezer models.

- Mbsmgroup also publishes technical sheets and compressor data for various Electrostar units, including power ratings and application notes that help match HP and wattage when selecting replacements.

Example image and catalog links

- Safe product galleries of Electrostar refrigerators, including 315‑liter and 328‑liter models, are available through regional appliance retailers and show external design, interior shelving and control layouts similar to the 16‑foot series.

- Technical documentation and catalog PDFs for domestic refrigeration compressors outline HP classes, wattage and typical cabinet sizes, providing useful guidance when evaluating or replacing the compressor in a 16‑foot fridge.