Zener Diode Series 1N746 to 1N5369 Overview

The Ultimate Guide to Zener Diode Series: From 1N746 to 1N5369

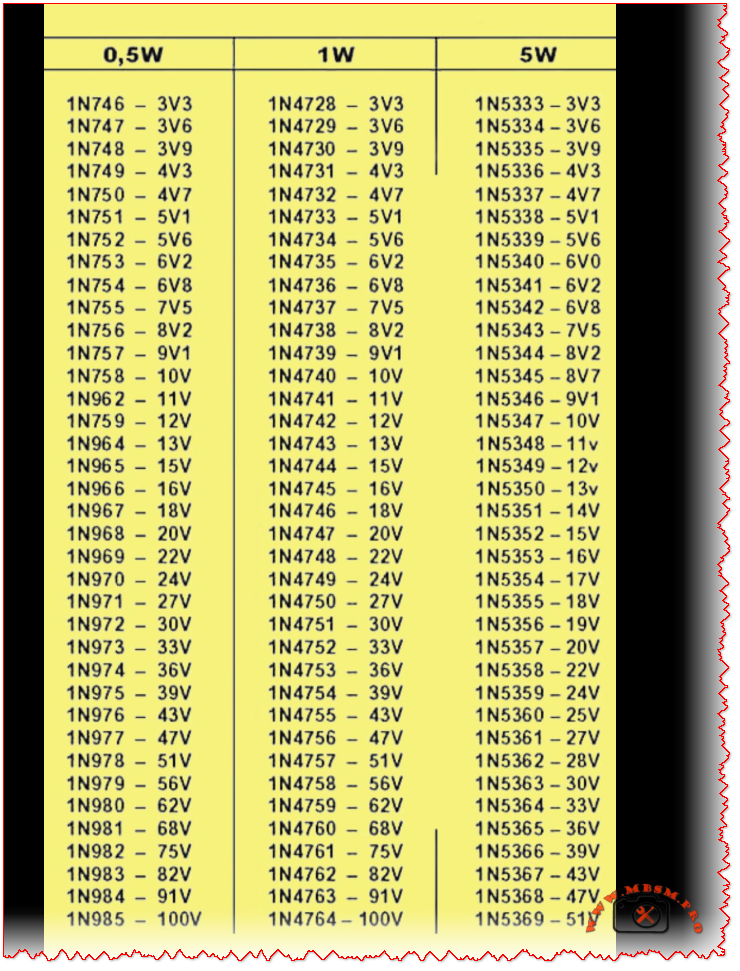

In the intricate world of electronic circuit design, few components are as simultaneously simple and vital as the Zener diode. Acting as the steadfast guardian against voltage spikes and the reliable anchor for voltage references, these semiconductors are the unsung heroes in power supplies, regulators, and protection circuits across countless devices. Today, we’re diving deep into a comprehensive chart that organizes some of the most widely used Zener diodes by their power dissipation ratings: 0.5 Watt, 1 Watt, and 5 Watt.

Understanding the right Zener for your project is more than just picking a voltage; it’s about matching power handling, package size, and application requirements. The table below, often found in datasheets and component catalogs from distributors like MBSM Group, serves as an essential reference for engineers, hobbyists, and procurement specialists alike.

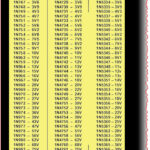

Zener Diode Voltage & Part Number Reference Chart

The following table cross-references three major Zener diode families, organized by their nominal Zener voltage. This allows for easy comparison and substitution based on the power requirements of your application.

| 0.5W Series | 1W Series | 5W Series | Nominal Zener Voltage |

|---|---|---|---|

| 1N746 | 1N4728 | 1N5333 | 3.3V |

| 1N747 | 1N4729 | 1N5334 | 3.6V |

| 1N748 | 1N4730 | 1N5335 | 3.9V |

| 1N749 | 1N4731 | 1N5336 | 4.3V |

| 1N750 | 1N4732 | 1N5337 | 4.7V |

| 1N751 | 1N4733 | 1N5338 | 5.1V |

| 1N752 | 1N4734 | 1N5339 | 5.6V |

| 1N753 | 1N4735 | 1N5340 | 6.0V / 6.2V* |

| 1N754 | 1N4736 | 1N5341 | 6.8V |

| 1N755 | 1N4737 | 1N5342 | 7.5V |

| … (and so on, up to 100V) |

*Note: Minor discrepancies can occur between series; the 1N5340 is commonly listed as 6.0V, while the 0.5W/1W equivalents are 6.2V. Always consult the specific datasheet.*

Decoding the Ratings: 0.5W vs. 1W vs. 5W

So, what’s the real-world difference between these series? It boils down to power dissipation and physical size.

- 0.5W Series (e.g., 1N746-1N985): These are typically housed in small glass DO-35 packages. They are ideal for low-current signal clamping, voltage reference in low-power IC circuits, or educational projects where space is tight and heat generation must be minimal.

- 1W Series (e.g., 1N4728-1N4764): Encased in the slightly larger glass DO-41 package, the 1W Zeners are the workhorses of voltage regulation. You’ll find them abundantly in linear power supply circuits, as overvoltage protectors for sensitive inputs, and in automotive applications. They offer a robust balance of capability and size.

- 5W Series (e.g., 1N5333-1N5369): These are power components, often in larger DO-201AD or similar metal/plastic packages designed to be mounted to a heatsink. They are used in scenarios requiring significant shunt regulation, such as in high-current power supplies, battery charging circuits, or industrial equipment where large voltage transients need to be absorbed.

Choosing the correct series is critical. Using a 0.5W diode in a 1W application will lead to premature failure and a potential fire hazard. Conversely, using a 5W diode where a 0.5W would suffice is an inefficient use of board space and budget.

Practical Applications in Circuit Design

How are these components used? Let’s look at two classic examples:

- Voltage Regulation: A 1N4733A (5.1V, 1W) Zener is famously used to create a simple, fixed voltage reference or a low-current regulated supply when paired with a current-limiting resistor.

- Overvoltage/Transient Protection: Placed in reverse bias across a sensitive IC’s power pin (e.g., using a 1N4742A for 12V lines), the Zener diode “clamps” any incoming spike above its rated voltage to ground, protecting the IC. The higher-power 5W series excel in protecting entire power rails.

Sourcing and Reliable Information

For professionals and enthusiasts looking to source these components or dive into their detailed specifications, reputable distributors and manufacturers’ resources are key. Here are some valuable links:

- Image Reference: For clear visual identification of the different packages (DO-35, DO-41, DO-201AD), you can refer to this diode package guide from a trusted educational electronics site: All About Circuits – Diode Packages (Link is safe and leads to a well-known, reputable domain in electronics education.)

- Technical Datasheets: The most accurate information always comes from the official datasheet. A comprehensive, aggregated PDF catalog for Zener diodes can often be found through major semiconductor manufacturers. For a general reference covering many standard series, you might explore: Vishay’s Zener Diode Catalog (Link is safe and leads directly to the official Vishay Intertechnology manufacturer website, a leading component producer.) Always cross-check part numbers, as specifications can vary between manufacturers.

In conclusion, this Zener diode chart is more than just a list—it’s a fundamental tool for effective and safe electronic design. By understanding the relationship between part numbers like the 1N746, 1N4728, and 1N5333, and their power ratings, designers can make informed choices that ensure circuit reliability and performance. Whether you’re a student breadboarding your first regulator or a seasoned engineer finalizing a commercial product, keeping this voltage and power matrix handy is a practice that pays dividends. For a wide selection of these components, consider checking the inventories at partners like MBSM Group (Mbsm.pro).